តុលា . 12, 2024 11:32 Back to list

custom fabrication table

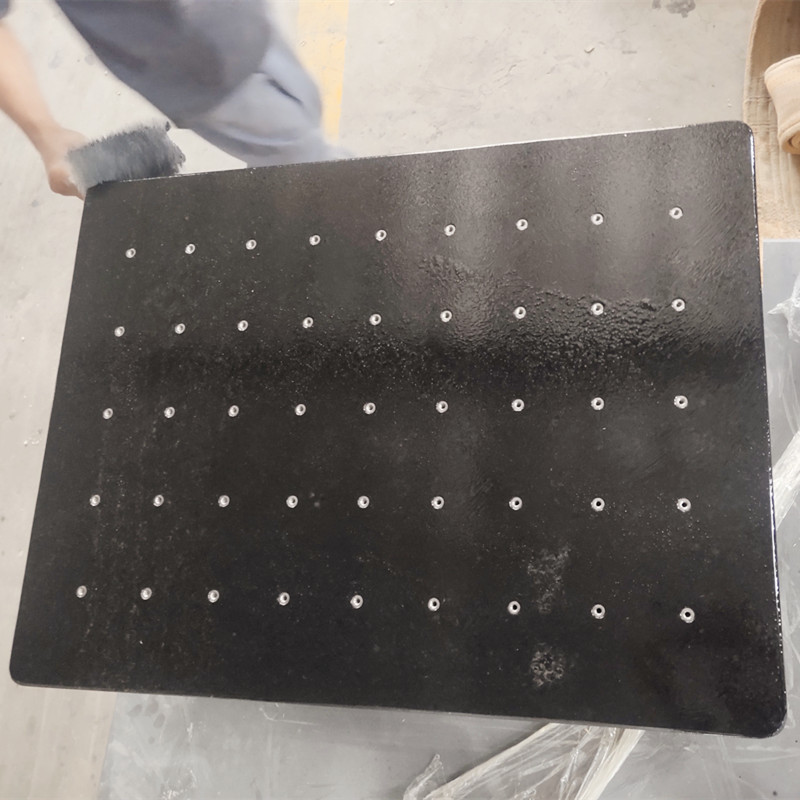

Customized Fabrication Tables Enhancing Efficiency and Versatility in Different Industries

In today’s fast-paced world, customization has become a crucial aspect of manufacturing across various industries. One area that has witnessed significant growth due to this trend is the field of custom fabrication tables. These tables are not just simple work surfaces; they are tailored solutions that can adapt to the unique needs of different projects and workflows, enhancing efficiency and productivity.

What is Custom Fabrication?

Custom fabrication refers to the process of creating tailored solutions to meet specific requirements. It includes a range of activities such as cutting, shaping, and assembling materials to produce components or structures designed for particular applications. This is particularly important in industries that require precision and adaptability, such as construction, manufacturing, and design.

Importance of Fabrication Tables

Fabrication tables serve as foundational work surfaces that support various manufacturing processes. The importance of these tables lies in their ability to enhance workflow, organization, and safety. They are designed to accommodate different types of materials—be it metal, wood, plastic, or composites—and can be customized to fit specific tasks.

Enhanced Workflow

One of the primary benefits of custom fabrication tables is that they can significantly enhance workflow. By creating a table that is specifically designed for the tasks at hand, businesses can optimize their operations. For instance, a custom table can be designed with built-in tools, measuring guides, and material handling systems, reducing the need for workers to move around frequently and search for tools. This streamlining of processes leads to increased efficiency and productivity.

Versatility in Design

Every industry has its unique requirements, and a one-size-fits-all approach often falls short. Customized fabrication tables can be designed in various dimensions and configurations to suit specific operations. For example, a welding table may require a specific height and surface material to accommodate high temperatures, while an assembly table may need integrated storage solutions for tools and components. This versatility allows businesses to tailor their setups to their unique production processes.

Improved Safety

Safety is paramount in any workplace, especially in manufacturing environments where heavy materials and machinery are prevalent. Custom fabrication tables can be designed with safety features such as rounded edges, non-slip surfaces, and integrated safety barriers. Furthermore, organizing tools and materials effectively on customized tables reduces clutter, minimizing the risk of accidents and enhancing overall workplace safety.

custom fabrication table

Industry Applications

The applications of custom fabrication tables are vast and varied

. Here are a few key industries where they play a vital roleManufacturing

In manufacturing settings, custom fabrication tables are invaluable for assembly lines, machining operations, and prototype development. They can be designed to hold specialized jigs, fixtures, or tools that improve the accuracy and speed of production processes.

Metalworking

For metalworking companies, having the right fabrication table is essential. Custom tables can accommodate welding machines, plasma cutters, and other tools, integrating power supply solutions and fume extraction systems to ensure safety and efficiency.

Woodworking

Woodworking requires precision and stability. Custom fabrication tables designed for this trade can include features like T-track systems for secure clamping and built-in dust collection systems that promote a cleaner workspace.

Automotive and Aerospace

In the automotive and aerospace industries, custom fabrication tables are used for assembly, maintenance, and inspection processes. They can be designed to support heavy components and equipped with adjustable heights to accommodate different tasks and workers.

Conclusion

The demand for custom fabrication tables continues to grow as businesses recognize the benefits they offer. These tables are not merely a work surface; they are multi-functional tools that enhance workflow, provide safety, and cater to the diverse needs of various industries. As technology advances and customization becomes increasingly accessible, the potential for custom fabrication tables to revolutionize workspaces and improve efficiency will only expand. Investing in these tailored solutions can lead to significant returns in productivity, innovation, and overall operational success. In a world where efficiency and adaptability are paramount, custom fabrication tables are an essential component for businesses striving to stay ahead of the curve.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS