កញ្ញា . 28, 2024 07:45 Back to list

Bore Gauge Specification Overview and Key Features for Precision Measurement

Bore Gauge Specifications Understanding Measurement Tools for Precision Engineering

Bore gauges are essential tools used in various industries to measure the internal diameter of cylindrical objects such as pipes, engine cylinders, and various mechanical components. Accurate measurement is crucial in manufacturing, automotive, aerospace, and mechanical engineering, making the specifications of bore gauges a vital topic. This article delves into the specifications, types, applications, and the significance of precision in bore gauge measurements.

Types of Bore Gauges

Bore gauges come in several types, each designed for specific measurement needs

1. Dial Bore Gauges These are the most common type of bore gauges and are equipped with a dial indicator. They measure the bore diameter through a probe that expands to touch the internal walls of the bore. The dial indicator displays the measurement, allowing users to monitor tolerances effectively.

2. Digital Bore Gauges With advancements in technology, digital bore gauges offer an electronic display of measurements. They provide improved accuracy, instant readings, and often have the capability to store measurements for further analysis.

3. Measuring Tapes and Calipers While not specifically bore gauges, these tools can measure larger or less accessible bores. However, their accuracy is not comparable to specialized bore gauges.

4. Internal Micrometers These are more complex tools used for precision measurements of small internal diameters. They require careful calibration and are ideal for high-precision applications.

Specification Factors

When selecting a bore gauge, several specifications should be taken into account

1. Measurement Range Bore gauges come in various measurement ranges, typically from a few millimeters to several centimeters, accommodating different applications. Knowing the bore size is crucial for selecting the appropriate gauge.

bore gauge specification

2. Resolution and Accuracy The precision of a bore gauge is often defined by its resolution and accuracy. Resolution refers to the smallest increment a gauge can measure, while accuracy indicates how close the measurement is to the true value. High-quality bore gauges generally have resolutions of 0.01 mm or better.

3. Calibration Regular calibration is vital for maintaining accuracy. Many bore gauges provide features for self-calibration or come with calibration certificates. Understanding the calibration process is necessary for ensuring the tool’s reliability.

4. Material and Durability Bore gauges are often made from high-quality materials that can withstand wear and tear. The durability of the gauge is especially important in industrial environments, where tools may be subjected to harsh conditions.

5. Ease of Use User-friendly designs improve efficiency. Features such as ergonomic handles, clear readouts, and easy measurement adjustments contribute significantly to the usability of bore gauges.

Applications of Bore Gauges

Bore gauges are widely used across various sectors including

- Manufacturing Ensuring parts fit together correctly and function properly. - Automotive Measuring engine component bores, crucial for performance and safety. - Machining Checking internal diameters during the production of precision parts. - Aerospace High precision is critical; bore gauges ensure that components meet stringent safety standards.

Importance of Precision

Precision in measurements is not merely a technical requirement; it directly impacts product quality, safety, and performance. In fields like aerospace and automotive engineering, even minute deviations in internal diameters can lead to catastrophic failures. Therefore, adhering to the specifications of bore gauges is paramount to maintaining high standards.

Conclusion

Bore gauges play an indispensable role in ensuring the accuracy and precision of internal measurements across various industries. Understanding their specifications—ranging from measurement range and accuracy to calibration and durability—allows engineers and technicians to select the most suitable tool for their needs. As industries continue to evolve, the demand for precision measurement tools like bore gauges will only increase, ensuring that these essential tools remain at the forefront of manufacturing and engineering excellence.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

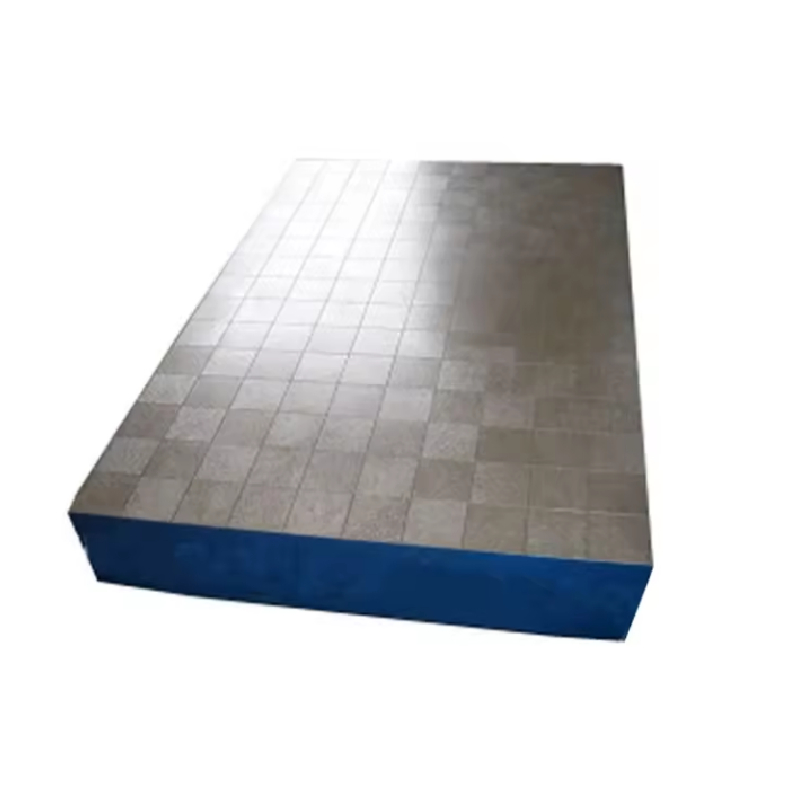

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS