ធ្នូ . 31, 2024 06:58 Back to list

ball type check valve manufacturers

Understanding Ball Type Check Valve Manufacturers

Ball type check valves are vital components in various fluid systems, providing crucial functionality by allowing the flow of fluid in one direction while preventing backflow. These valves find applications in numerous industries, including oil and gas, water treatment, chemical processing, and HVAC systems. The effectiveness and longevity of these valves hinge largely on the quality of the manufacturers producing them. Understanding the landscape of ball type check valve manufacturers is essential for selecting the right products for industrial applications.

Key Features of Ball Type Check Valves

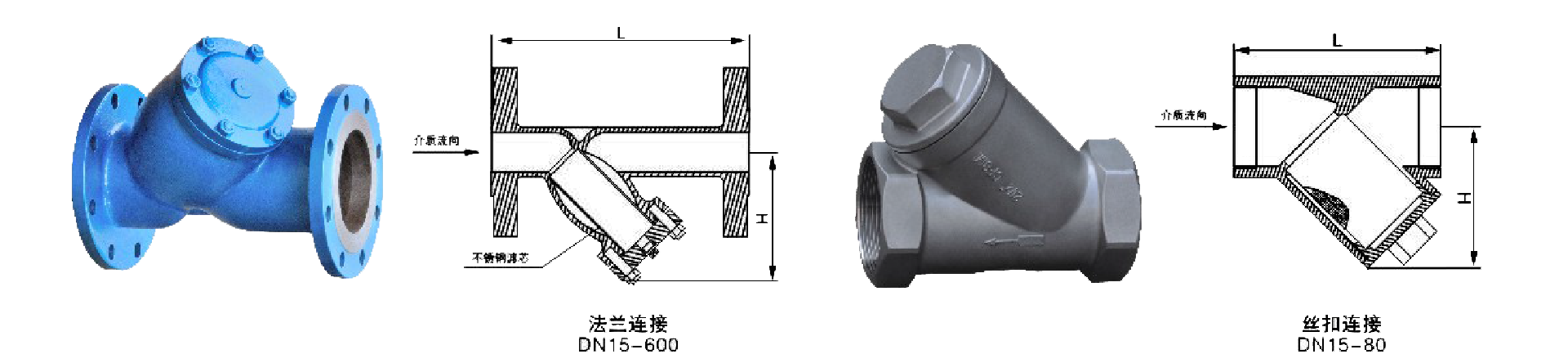

Before delving into manufacturers, it's important to highlight the features that make ball type check valves special. These valves operate based on a basic principle where a ball sits in a seat, allowing flow in one direction while sealing off the passage when fluid attempts to flow backwards. This design minimizes pressure drop, making it efficient for various applications. Furthermore, the simplicity of the design ensures durability and reduces the potential for leakage, which is a critical factor in maintaining system integrity.

The Role of Manufacturers

The ball type check valve market includes numerous manufacturers, each vying to present their unique values. When assessing manufacturers, several factors come into play

1. Quality Assurance Leading manufacturers comply with international quality standards, such as ISO 9001. They conduct rigorous testing during the manufacturing process to ensure the reliability and longevity of their valves. A commitment to quality is crucial since faulty valves can lead to leakage, costly downtimes, and safety hazards.

2. Material Selection Different applications require different materials. Top manufacturers offer a range of options, including brass, stainless steel, and PVC. The choice of material affects the valve's durability and resistance to corrosive substances. A good manufacturer will guide customers in selecting the right material based on their specific applications.

3. Customization Many manufacturers understand that the needs of customers can vary greatly. This has led some companies to offer custom solutions, designed to meet specific performance standards or unique installation challenges. This flexibility can be a significant advantage in industries where standard solutions are inadequate.

ball type check valve manufacturers

4. Innovative Technology The best manufacturers invest in research and development to produce valves that are more efficient, easier to install, and require less maintenance. Innovations such as improved sealing technology and enhanced flow characteristics can bring substantial benefits to end-users.

5. Customer Support and Service Manufacturing a valve is just one part of the equation; providing excellent customer service is equally important. Leading manufacturers often have dedicated support teams to assist with installation, maintenance, and troubleshooting, ensuring that customers maximize their investment.

Leading Manufacturers in the Market

While there are many manufacturers globally, a few have established themselves as leaders in the ball type check valve market

- Kitz Corporation Known for their high-quality valves, Kitz has a long history and wide-ranging product line, making them a trusted choice in various industries. - Apollo Valves Apollo offers a robust selection of ball check valves, focusing on innovative design and reliability. They are particularly recognized for their application in HVAC and plumbing systems.

- John Guest Specializing in high-quality plastic valves, John Guest plays a crucial role in industries that require lightweight and corrosion-resistant solutions, like food and beverage processing.

- Flowserve With a strong global presence, Flowserve manufactures an extensive range of valve products, including ball check valves tailored for high-pressure applications in the oil and gas sector.

Conclusion

Understanding the landscape of ball type check valve manufacturers is crucial for anyone involved in fluid system design or maintenance. The right manufacturer can provide not only high-quality products but also essential support and guidance throughout the selection process. By focusing on manufacturers that prioritize quality, innovation, customization, and customer service, businesses can ensure reliable performance and safety in their fluid handling systems. Choosing the right ball type check valve can ultimately lead to improved operational efficiency and reduced maintenance costs, making it a vital investment for any industrial setting.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS