កុម្ភៈ . 03, 2025 03:33 Back to list

butterfly valve types

The 3-inch stainless steel butterfly valve stands out as a crucial component in various industrial applications, where precise control of fluid flow is required. Its robust design and superior material make it an ideal choice for systems handling aggressive media and demanding environments. Drawing from years of industry experience, the following insights unveil why the stainless steel butterfly valve continues to be a preferred option for engineers and technicians across sectors.

Trustworthiness is built through transparency and rigorous quality control. Many top manufacturers provide detailed documentation and performance reports for their valves, which include pressure and temperature ratings, lifespan under specific conditions, and material compatibility assessments. This transparency allows purchasers to make informed decisions, fostering trust in both the product and the brand. Those in procurement and project management roles often prefer suppliers who can demonstrate a track record of reliability and customer satisfaction through case studies and client testimonials. A key factor that underlines the dominance of stainless steel butterfly valves in the market is their adaptability. These valves can be customized with different disc materials, linings, and actuators to suit unique operational needs. For example, a valve equipped with an EPDM lining might be selected for its superior chemical resistance in acidic environments, whereas a PTFE-lined valve might be chosen for its non-reactivity in pharmaceutical applications. In conclusion, the 3-inch stainless steel butterfly valve encapsulates a blend of experience-backed reliability, specialized expertise, authoritative design, and trustworthy performance. By consistently meeting the rigorous demands of diverse industries, these valves reinforce their status as indispensable components in fluid control systems. As industries evolve, so does the technology surrounding butterfly valves, promising even greater efficiency and functionality in future iterations. Embracing these innovations can lead to significant improvements in operational efficiency, safety, and cost-effectiveness, establishing stainless steel butterfly valves as a cornerstone in industrial fluid management solutions.

Trustworthiness is built through transparency and rigorous quality control. Many top manufacturers provide detailed documentation and performance reports for their valves, which include pressure and temperature ratings, lifespan under specific conditions, and material compatibility assessments. This transparency allows purchasers to make informed decisions, fostering trust in both the product and the brand. Those in procurement and project management roles often prefer suppliers who can demonstrate a track record of reliability and customer satisfaction through case studies and client testimonials. A key factor that underlines the dominance of stainless steel butterfly valves in the market is their adaptability. These valves can be customized with different disc materials, linings, and actuators to suit unique operational needs. For example, a valve equipped with an EPDM lining might be selected for its superior chemical resistance in acidic environments, whereas a PTFE-lined valve might be chosen for its non-reactivity in pharmaceutical applications. In conclusion, the 3-inch stainless steel butterfly valve encapsulates a blend of experience-backed reliability, specialized expertise, authoritative design, and trustworthy performance. By consistently meeting the rigorous demands of diverse industries, these valves reinforce their status as indispensable components in fluid control systems. As industries evolve, so does the technology surrounding butterfly valves, promising even greater efficiency and functionality in future iterations. Embracing these innovations can lead to significant improvements in operational efficiency, safety, and cost-effectiveness, establishing stainless steel butterfly valves as a cornerstone in industrial fluid management solutions.

Next:

Latest news

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

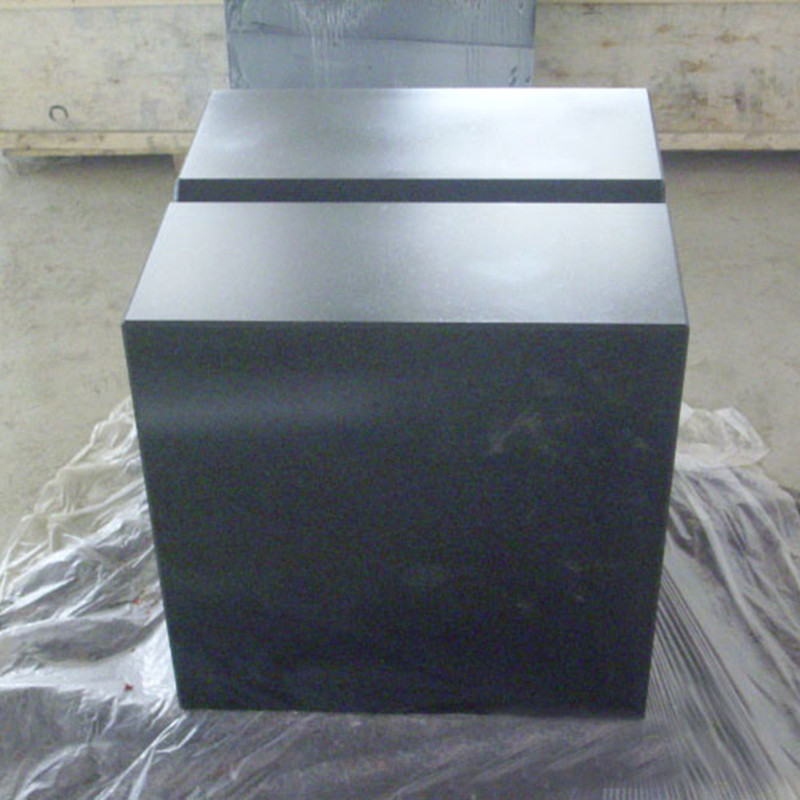

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS