វិច្ឆិកា . 04, 2024 19:00 Back to list

300 gate valve

The Importance of 300% Gate Valves in Industrial Applications

Industrial processes often rely on various types of valves to regulate fluid flow, ensure safety, and maintain operational efficiency. Among the many types of valves available, the 300% gate valve has emerged as a critical component in various applications. This article will explore the significance, functionality, and advantages of 300% gate valves in industrial settings.

The Importance of 300% Gate Valves in Industrial Applications

One of the primary advantages of using 300% gate valves is their ability to provide a tight seal. This ensures that there is minimal leakage when the valve is in the closed position, which is crucial in maintaining system integrity and preventing environmental contamination. Additionally, they can handle viscous fluids, making them suitable for a wide range of applications, from crude oil transport to chemical manufacturing.

300 gate valve

The design of a gate valve allows for low flow resistance, which means that when the valve is fully open, there is little obstruction to the fluid's movement. This ability to minimize flow resistance is particularly important in processes requiring high flow rates and efficiency. In contrast to other types of valves, such as globe or ball valves, gate valves can maintain lower operational costs by reducing energy consumption and wear on pumps.

Another significant aspect of 300% gate valves is their longevity and durability. Constructed from robust materials such as stainless steel or cast iron, these valves can withstand harsh operating conditions, including high temperatures and corrosive environments. This durability not only extends the lifespan of the valve itself but also contributes to overall system reliability and reduces maintenance costs over time.

Installation and maintenance of gate valves are generally straightforward, further enhancing their appeal in industrial settings. With fewer moving parts than other valve types, there is less that can go wrong, which streamlines the maintenance process. Moreover, regular inspections and prompt repairs can ensure optimal performance, making them a low-maintenance option for many operators.

In conclusion, the 300% gate valve plays an essential role in a wide array of industrial applications. Its ability to handle high pressures, maintain low flow resistance, offer a tight seal, and its robust construction makes it an indispensable asset in ensuring the efficiency and safety of industrial processes. As industries continue to evolve and demand more reliable solutions, the significance of high-performance gate valves like the 300% variant cannot be overstated.

-

Thread Micrometer Set FeaturesNewsJul.04,2025

-

Right Angle Ruler Tool for WoodworkingNewsJul.04,2025

-

Precision Frame Level Calibration StepsNewsJul.04,2025

-

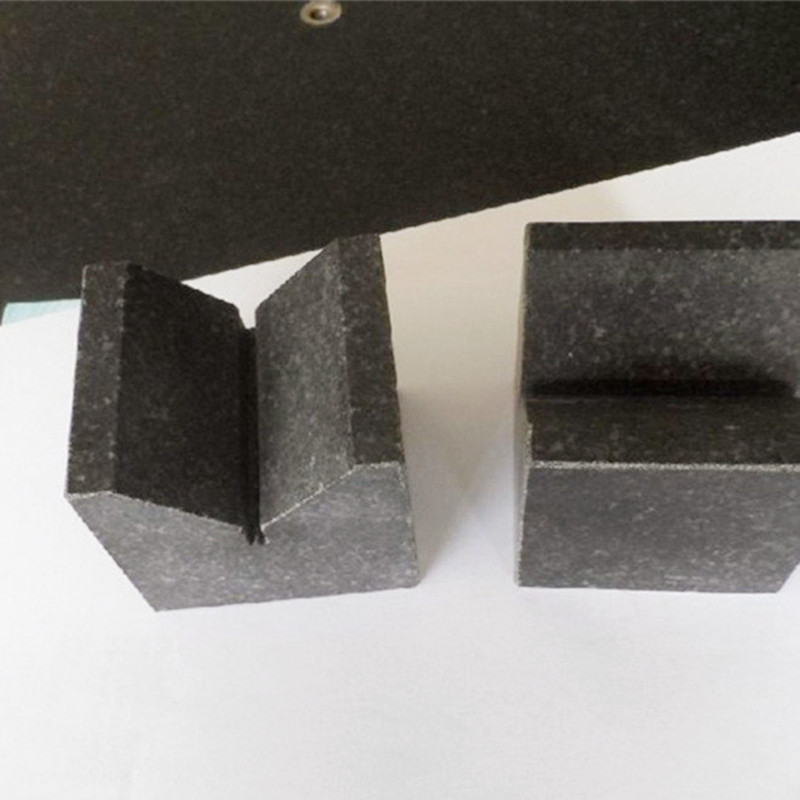

Magnetic Vee Block MaterialsNewsJul.04,2025

-

Heavy Duty Ground Anchors in MiningNewsJul.04,2025

-

Features of Welding Table Cast IronNewsJul.04,2025

Related PRODUCTS