Қар . 15, 2024 23:18 Back to list

backcheck valve

Understanding Backcheck Valves Function, Types, and Applications

Backcheck valves are essential components in various fluid systems, primarily used to prevent backflow and ensure the smooth, unidirectional flow of fluids. These valves are pivotal in many industrial and residential applications, where controlling the flow of liquids or gases is critical. This article delves into the function, types, and applications of backcheck valves, highlighting their importance in maintaining system efficiency and safety.

Function of Backcheck Valves

The primary function of a backcheck valve is to allow fluid to flow in one direction while preventing reverse flow. This is crucial in systems where backflow could cause contamination, equipment damage, or system failure. For instance, in a heating system, if the water were to flow back into the boiler, it could lead to overheating and potential damage. Backcheck valves eliminate this risk by closing automatically when there is a reverse flow.

When fluid flows in the intended direction, the valve opens, allowing the fluid to pass through. However, if there is an attempt for fluid to flow backward, the valve closes, effectively creating a barrier. This one-way flow is critical in various applications, ensuring operational safety and efficiency.

Types of Backcheck Valves

There are several types of backcheck valves, each designed for specific applications and operating conditions

. Here are some of the most common types1. Swing Check Valve This type features a hinged disc that swings open to allow flow and swings closed under backflow conditions. Swing check valves are typically used in larger diameter pipes and are favored for their simple design and reliability.

2. Lift Check Valve Unlike swing check valves, lift check valves operate using a vertically moving disc or ball that lifts off its seat when forward flow occurs. This type is more suitable for high-pressure systems where there is a need for a tighter seal against backflow.

3. Wafer Check Valve Compact and lightweight, wafer check valves are installed between flanges in a piping system. They offer low flow resistance and are often used in water and wastewater applications.

4. Dual Plate Check Valve This type uses two plates that pivot around a central axis. Dual plate check valves are known for their quick response to changes in flow direction and are commonly used in high-flow applications.

backcheck valve

5. Spring Check Valve This valve incorporates a spring mechanism that assists in closing the valve under backflow conditions. It is particularly useful in cases where gravitational force alone may not reliably close the valve.

Applications of Backcheck Valves

Backcheck valves are employed across various industries, demonstrating their versatility and critical role in fluid control systems. Some notable applications include

- Water Supply Systems In municipal water supply systems, backcheck valves prevent contamination from backflow and protect water quality.

- Industrial Processes Many manufacturing processes use backcheck valves to maintain the integrity of fluid transfer systems, protecting equipment from damaging backflow.

- HVAC Systems In heating, ventilation, and air conditioning systems, backcheck valves ensure that heated or cooled air flows in the desired direction, enhancing efficiency.

- Fire Suppression Systems Backcheck valves are also essential in fire suppression systems, preventing water from flowing back into storage tanks, thus ensuring the system is always ready in case of emergency.

- Chemical Processing In chemical plants, backcheck valves are critical in preventing hazardous backflow, maintaining safety and compliance with regulations.

Conclusion

Backcheck valves play an integral role in numerous fluid handling applications by preventing backflow and ensuring the safe operation of various systems. Understanding the different types of backcheck valves and their respective applications can aid in selecting the most appropriate valve for specific needs. Whether in residential plumbing, industrial manufacturing, or chemical processing, the significance of backcheck valves cannot be overstated. They are vital not only for operational efficiency but also for ensuring safety and preventing potential hazards in fluid systems. As industries continue to evolve, the innovation and development of backcheck valve technology will undoubtedly play a crucial role in future fluid management solutions.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

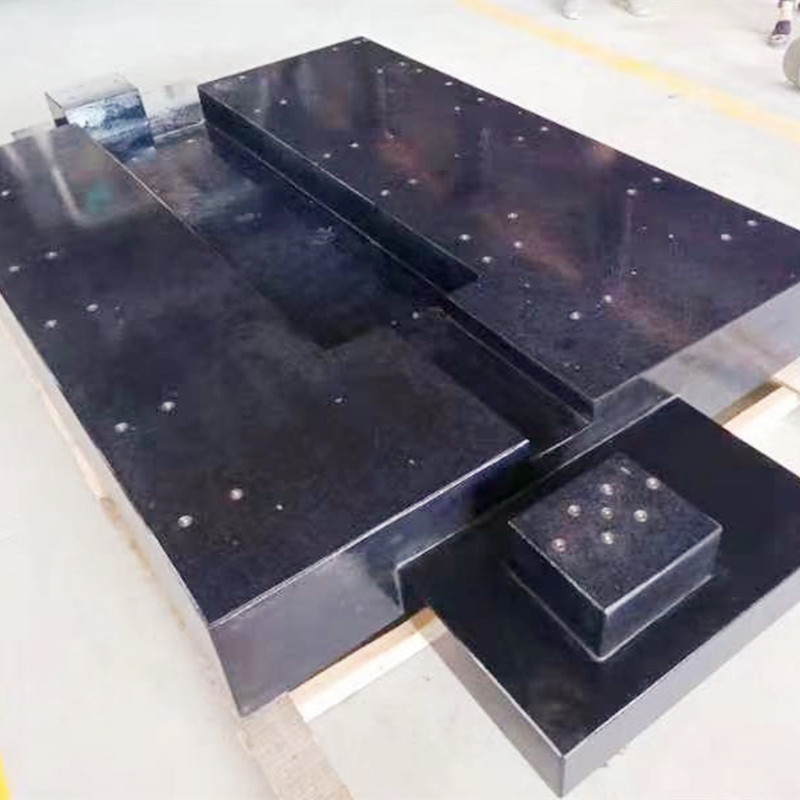

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS