Жел . 17, 2024 00:50 Back to list

3 gate valve

Understanding the 3% Gate Valve Characteristics and Applications

Gate valves are essential components in various piping systems, providing a reliable means of controlling fluid flow. Among the myriad of gate valves available, the 3% gate valve has gained attention for its unique design and performance characteristics. This article elucidates the features, benefits, and common applications of the 3% gate valve, highlighting its significance in fluid management.

What is a Gate Valve?

A gate valve is a type of valve that operates by lifting a gate out of the path of the fluid. This mechanism allows for minimal resistance and pressure drop when the valve is fully open, making it an ideal choice for applications requiring unrestricted flow. Gate valves are commonly used in water, oil, gas, and other fluid systems, where they serve primarily as on/off valves, rather than flow regulators.

The 3% Gate Valve Explained

The term 3% gate valve typically refers to the design and performance parameters of the valve, specifically about how it affects the flow characteristics within a system. A gate valve labeled as 3% indicates that it maintains a flow efficiency that minimizes pressure loss to just 3% when fully open. This is particularly beneficial in applications where maintaining system pressure is crucial for efficient operation.

Key Features

1. Low Flow Resistance One of the primary advantages of the 3% gate valve is its low flow resistance. The gate design allows fluid to move through the valve with minimal disruption, resulting in lower energy costs and improved system efficiency.

2. Versatile Materials 3% gate valves can be manufactured from various materials, such as carbon steel, stainless steel, and plastic. This versatility enables their use in different environments, including corrosive applications and high-temperature situations.

3. Durability These valves are engineered for longevity, with robust construction that withstands wear and tear. This quality reduces maintenance requirements and prolongs the lifespan of the valve.

3 gate valve

4. Full Bore Design A full bore gate valve has a diameter equal to the pipe diameter, ensuring that there is no obstruction or restriction in fluid flow. This design feature contributes to the 3% gate valve's effectiveness in maintaining system efficiency.

Applications

3% gate valves find application across a diverse range of industries

- Water Supply In municipal water systems, 3% gate valves are deployed to control the flow of water, ensuring that supply lines can be shut off during maintenance without significant pressure loss in the system.

- Oil and Gas Industry These valves are crucial in oil and gas pipelines where high flow rates are required. Their efficiency helps in transporting fluids over long distances, thus reducing operational costs.

- Chemical Processing In processes where aggressive chemicals are involved, the valve's durable construction and resistance to corrosion make it a suitable choice, helping to ensure safe and efficient operations.

- Power Generation The energy sector utilizes 3% gate valves in various stages of power generation, particularly in cooling water systems, which require reliable and efficient flow control.

Conclusion

The 3% gate valve is an invaluable asset in the world of fluid control, combining efficiency, durability, and versatility. Its low flow resistance and robust design make it particularly advantageous in various industrial applications, from water supply systems to oil and gas transportation. As industries continue to seek optimization in their fluid management systems, valves like the 3% gate valve will remain at the forefront of engineering solutions, emphasizing the importance of reliable flow control in modern infrastructure. Understanding and utilizing such valves can significantly enhance operational efficiency and reduce costs in numerous applications.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

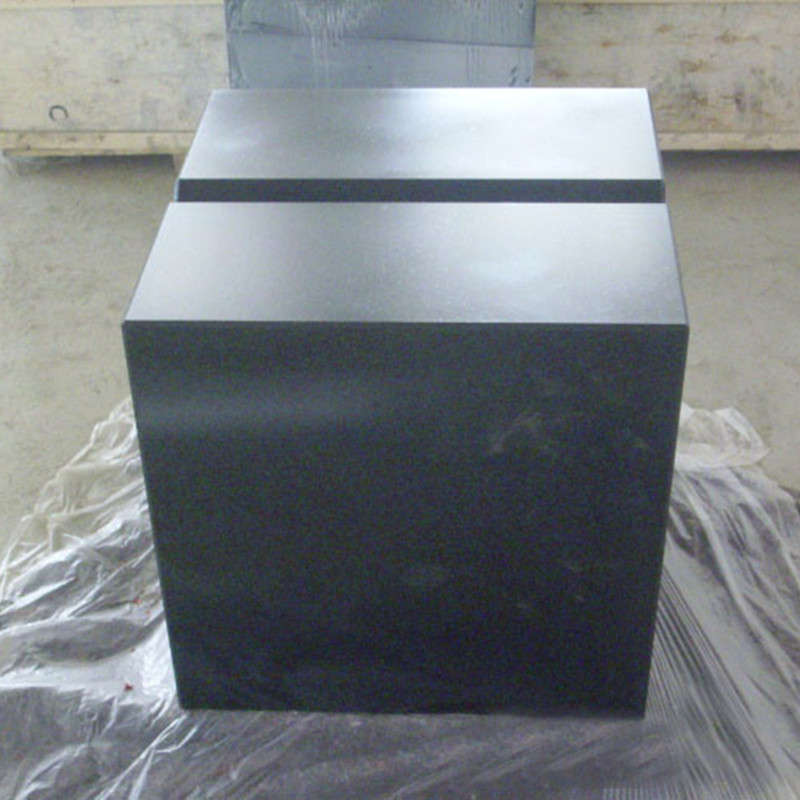

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS