Jun . 19, 2025 09:33 Bali menyang dhaptar

Plug Ring Gauge Applications in Automotive Quality Control

In the automotive industry, precision and reliability are non-negotiable. Even the smallest component defect can compromise safety, performance, and brand reputation. Plug gauges, plug ring gauges, and small hole gauges play pivotal roles in maintaining stringent quality control standards. These tools ensure dimensional accuracy, fit, and functionality of critical automotive parts, from engine components to intricate assemblies. Let’s explore their applications and how they elevate manufacturing excellence.

The Role of Plug Gauge in Precision Measurement

A plug gauge is a cylindrical measuring instrument designed to check the diameter of holes, slots, or other cylindrical bores. In automotive manufacturing, where holes of various sizes exist in parts like cylinder heads, transmission housings, and brake components, these gauges are indispensable. They verify whether a hole's diameter falls within the specified tolerance range, ensuring compatibility with mating parts such as bolts, pins, or shafts.

For instance, in engine cylinder production, plug gauges ensure that the diameter of coolant passages and oil galleries meets design specifications. Inaccurate hole dimensions could lead to fluid leaks, overheating, or lubrication failures—issues that directly impact engine longevity. By providing quick, reliable measurements, plug gauges help manufacturers identify defects early in the production cycle, reducing waste and rework costs. Their simple yet effective design allows for easy integration into both manual inspection processes and automated quality control systems, making them a staple in automotive factories worldwide.

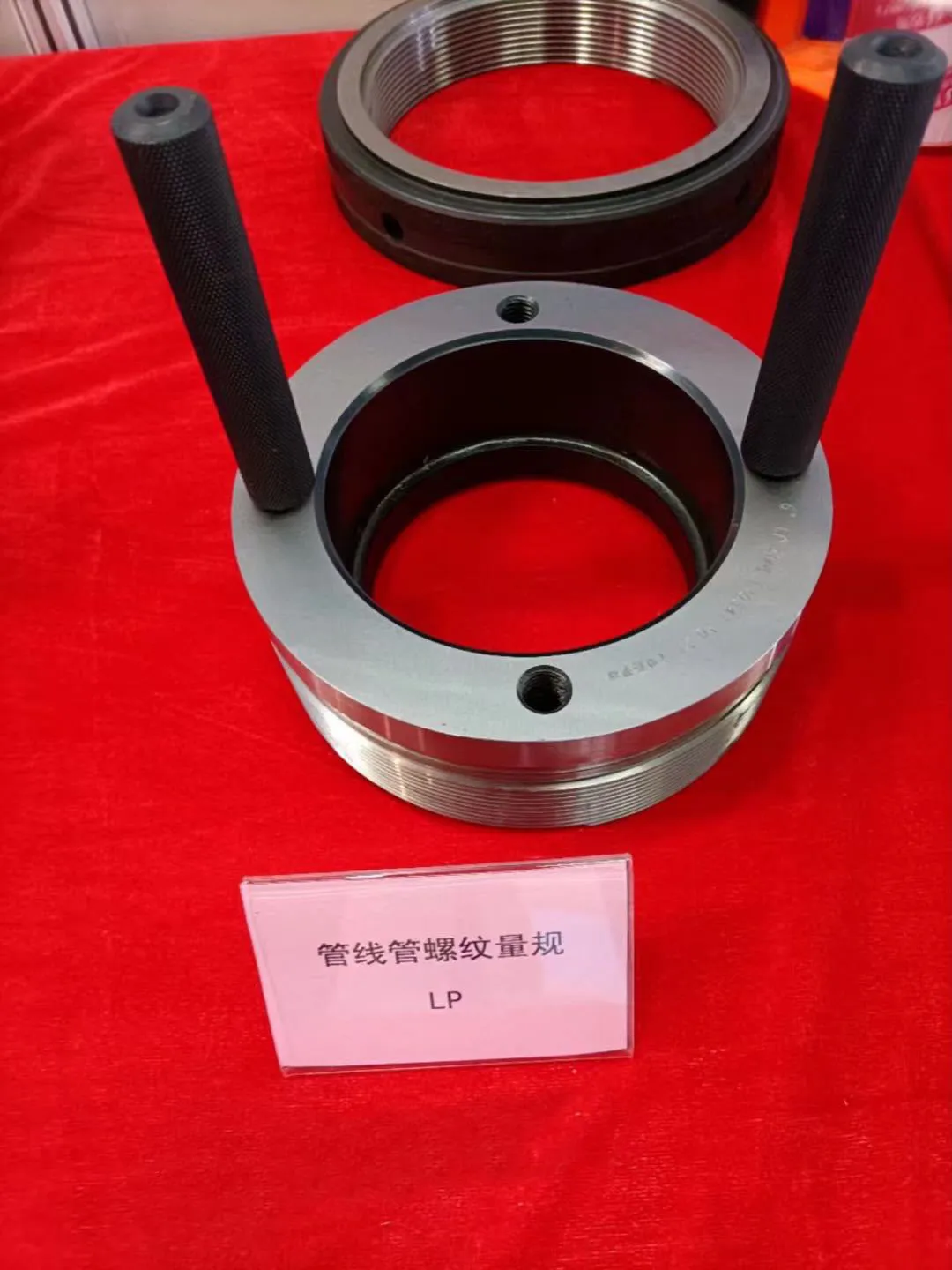

Ensuring Shaft and Hole Compatibility with Plug Ring Gauge

While plug gauges focus on hole measurements, plug ring gauges are designed to check the external diameter of shafts, pins, and other cylindrical components. In automotive assembly, proper shaft-hole fit is critical for smooth mechanical operation. A misaligned or incorrectly sized shaft can cause excessive wear, noise, or even mechanical failure. Plug ring gauges help manufacturers ensure that shafts—such as those in transmissions, drive axles, or steering systems—meet the precise dimensional requirements for optimal fit with their corresponding holes.

Consider a transmission shaft that must fit seamlessly into a gear housing. A plug ring gauge quickly determines if the shaft's diameter is within the allowable tolerance, preventing issues like play (which causes vibration) or binding (which leads to excessive friction). These gauges are often used in conjunction with plug gauges to achieve a "go/no-go" inspection standard, where a part is only approved if both the hole and shaft gauges confirm proper fit. This dual-check system is vital in high-stakes applications where component interaction directly affects vehicle performance and safety.

Small Hole Gauge: Mastering Micro-Dimensions in Automotive Components

As automotive technology evolves, components are becoming smaller and more complex, especially in areas like fuel injection systems, electronic connectors, and hydraulic valves. These applications require precise measurement of small holes—often with diameters as tiny as a few millimeters or less. Traditional gauges may lack the sensitivity or design to measure such micro-dimensions accurately, making the ukuran bolongan cilik an essential tool.

Small hole gauges are engineered with fine-tipped probes and high-precision mechanisms to measure intricate bores in parts like fuel injector nozzles, which require ultra-small holes for optimal fuel atomization. Inaccurate measurements here could lead to poor combustion, reduced fuel efficiency, and increased emissions. These gauges also excel in inspecting holes in electronic components, such as connector sockets, where dimensional precision ensures reliable electrical contact. By addressing the unique challenges of small-scale measurements, small hole gauges enable manufacturers to meet the strict standards of modern automotive engineering, where every micron matters.

FAQ: Maximizing the Value of Plug Gauge, Plug Ring Gauge, and Small Hole Gauge

What Are the Key Advantages of Using Plug Ring Gauge in Automotive Production?

The primary benefits include unmatched precision, rapid inspection capability, and durability. Plug ring gauges offer immediate "go/no-go" results, reducing inspection time while ensuring consistent shaft diameter compliance. Their robust construction withstands frequent use in harsh manufacturing environments, providing long-term reliability and cost-effectiveness.

How Does a Small Hole Gauge Improve Quality Control for Miniature Components?

Small hole gauges are specifically designed to measure diameters in the sub-millimeter range with high accuracy. They feature adjustable probes and ergonomic designs that allow access to hard-to-reach small holes, ensuring no dimension is overlooked. This is critical for components like micro-valves or sensor housings, where dimensional errors can disrupt entire systems.

Can Plug Gauges Be Used for Both Manual and Automated Inspections?

Yes, plug gauges are highly versatile. Manual models are ideal for quick spot-checks on the factory floor, while automated versions can be integrated into robotic arms or coordinate measuring machines (CMMs) for high-volume, repetitive inspections. This flexibility makes them suitable for all stages of production, from prototyping to mass manufacturing.

What Makes Plug Ring Gauges Better Than Other Shaft-Measuring Tools?

Unlike calipers or micrometers, which require operator skill and time to interpret readings, plug ring gauges provide instant pass/fail results. This minimizes human error and speeds up quality control processes, especially in high-throughput automotive assembly lines where efficiency and accuracy are equally important.

How Can I Ensure Longevity and Accuracy of Plug Gauges?

Regular calibration and proper maintenance are key. Store gauges in clean, dry environments, avoid dropping or mishandling, and follow the manufacturer's recommended calibration schedule. Investing in high-quality gauges from trusted suppliers ensures they retain their precision over years of use, providing a solid return on investment for your quality control operations.

In conclusion, plug gauges, plug ring gauges, and small hole gauges are not just tools—they are the backbone of automotive quality control. By ensuring dimensional accuracy at every stage of production, these instruments safeguard against defects, enhance component performance, and uphold the rigorous standards that modern vehicles demand. Whether you're inspecting large engine components or tiny electronic parts, the right gauge can make all the difference in delivering products that combine safety, reliability, and excellence.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlKabarAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseKabarAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsKabarAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesKabarAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingKabarAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlKabarAug.05,2025

PRODUK sing gegandhengan