Jul . 09, 2025 11:42 Bali menyang dhaptar

Calibration Methods for a Measurement Platform

Proper calibration of your measurement platform ensures accuracy and reliability in all inspection processes. Understanding the various techniques for platform inspection helps maintain the precision of your inspection platform over time. This guide covers essential calibration methods and best practices.

Standard Calibration Procedures for Measurement Platform

- Laser interferometry provides the most accurate calibration for high-precision measurement platform units

• Electronic levels establish the flatness and levelness of your inspection platform

• Comparator methods using gauge blocks verify the accuracy of platform inspection equipment

• Straightedge testing checks for surface deviations across the entire measurement platform

• Repeatability tests confirm consistent performance of your inspection platform

|

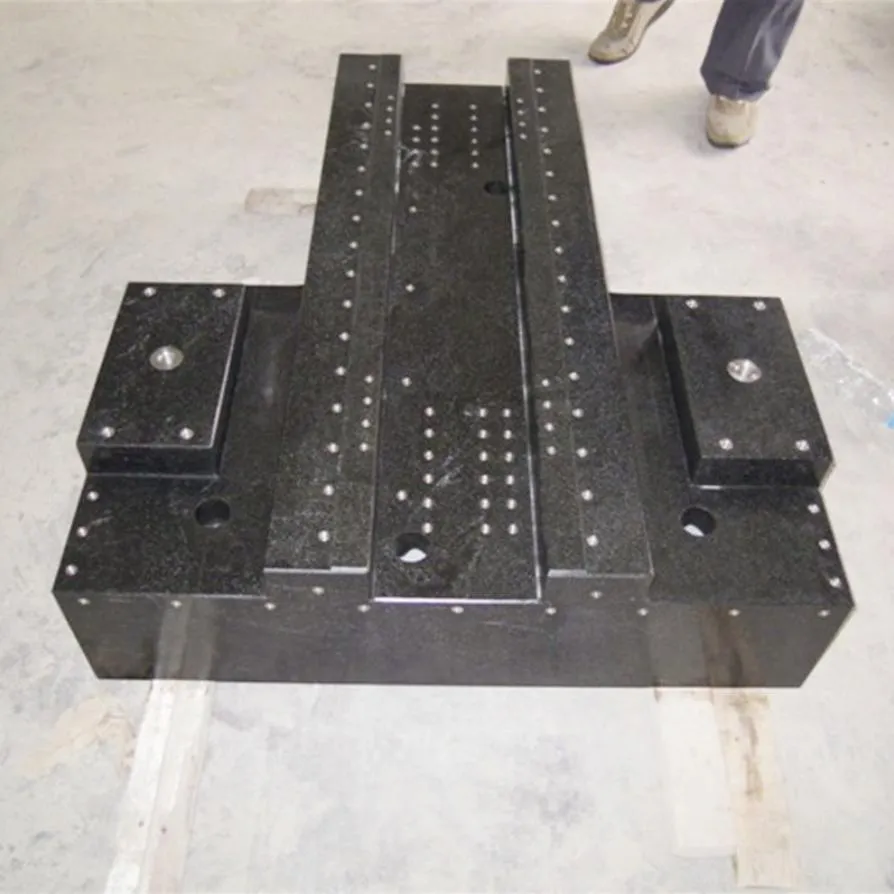

Item |

Rincian |

|

Place of Origin |

Hebei |

|

Brand Name |

Storan |

|

Model Number |

1005 |

|

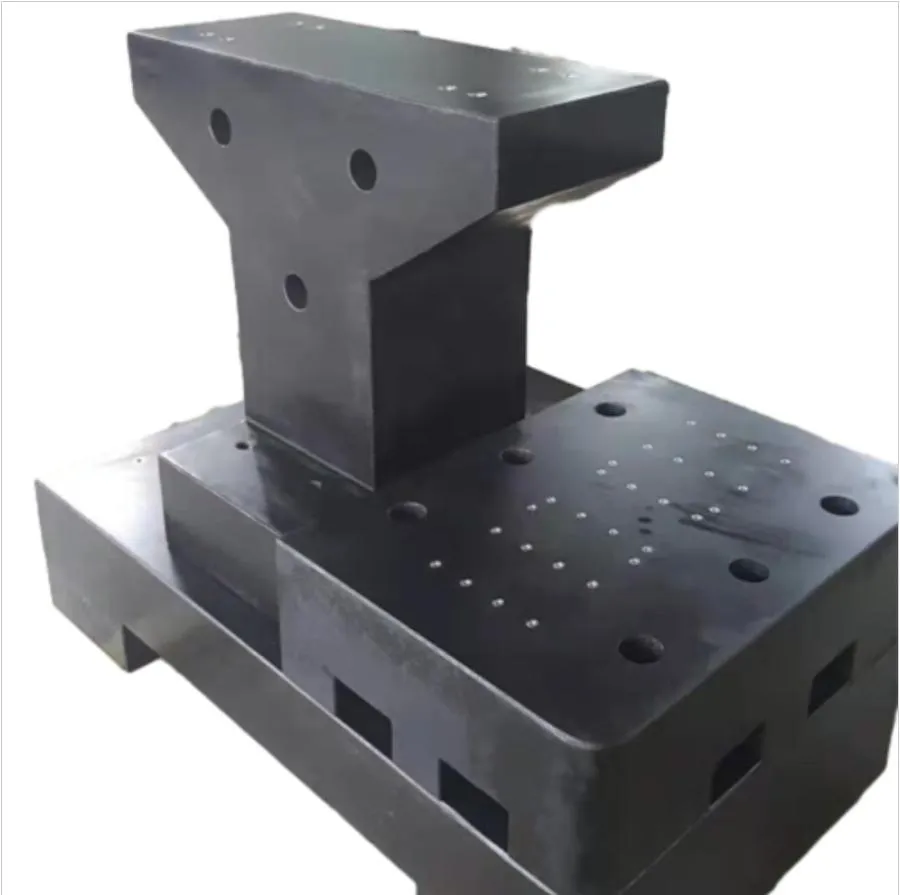

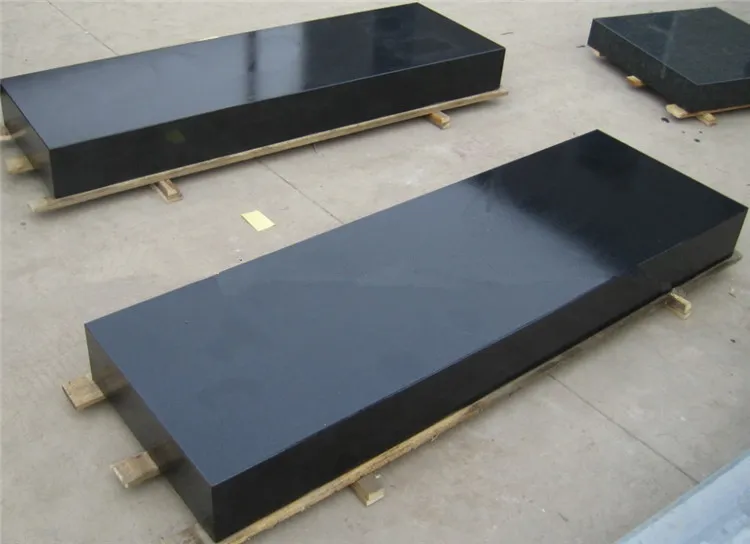

Materi |

Granit |

|

warna |

Black |

|

Paket |

Plywood box |

|

Port |

Tianjin |

|

Ukuran |

Customized |

|

Fungsi |

Test measurement |

|

Shipping |

By sea |

|

Packing |

Plywood Box |

|

Keyword |

Granite 00grade table customized |

|

Packaging Details |

Plywood |

|

Supply Ability |

1200 Piece/Pieces per Day |

|

kelas |

00 |

|

Kapadhetan |

2500 - 2600kg/Cubic metre |

|

Customized |

Yes |

|

Hardness |

More than HS70 |

|

Compressive strength |

245 - 254N/m |

|

Water absorption |

Less than 0.13% |

|

Elastic coefficient |

1.3 - 1.5*10^6kg/Square centimetre |

|

Aplikasi |

Industrial measurement, laboratory, precision parts assembly, vehicle maintenance |

Environmental Considerations for Platform Inspection

- Maintain stable temperature conditions during measurement platformcalibration (20°C ideal)

• Control humidity levels to prevent expansion/contraction of inspection platformcomponents

• Isolate from vibrations that could affect platform inspection accuracy

• Ensure proper lighting for visual checks during measurement platform calibration

• Allow sufficient warm-up time for electronic inspection platform equipment

Frequency Requirements for Measurement Platform Calibration

- High-use platform inspectionequipment requires quarterly calibration checks

• Normal-use measurement platformunits should undergo biannual calibration

• Annual calibration suffices for lightly used inspection platform setups

• Immediate recalibration needed after any measurement platform impact or damage

• Document all platform inspection calibration dates and results

Certification Standards for Inspection Platform

- ISO 9001 certification ensures proper measurement platformcalibration procedures

• NIST traceability required for certified inspection platformcalibration

• ISO/IEC 17025 accreditation for labs performing platform inspection calibration

• Manufacturer-specific standards may apply to certain measurement platform models

• Industry-specific regulations govern some specialized inspection platform applications

Maintaining Calibration Integrity for Platform Inspection

- Establish controlled access to calibrated measurement platformequipment

• Implement handling procedures to prevent inspection platformdamage

• Use proper lifting techniques when moving heavy platform inspection equipment

• Store measurement platform components in designated protective areas

• Train all personnel on proper inspection platform usage protocols

Platform Pengukuran FAQS

Q: How does a measurement platform differ from an inspection platform in industrial use?

A: A measurement platform focuses on capturing precise dimensional, geometric, or physical data (e.g., using sensors for length, angle, or vibration). An inspection platform centers on evaluating if products/components meet quality standards—though they overlap, the former emphasizes data collection, the latter compliance checks.

Q: What key features make a measurement platform suitable for laboratory precision work?

A: Labs need measurement platforms with ultra - flat, stable surfaces (minimizing vibration/interference), high - precision calibration (e.g., grade 00 granite for low thermal expansion), and compatibility with advanced sensors (laser scanners, force gauges). These ensure repeatable, accurate data for R&D or testing.

Q: Can a platform inspection identify hidden wear in a measurement platform?

A: Yes! Platform inspection checks for surface scratches, subsurface cracks (via ultrasonic tests), or degraded flatness (using autocollimators). Regular inspections catch wear early—critical for maintaining the platform’s measurement accuracy over time.

Q: How to choose between a fixed vs. portable measurement platform for fieldwork?

A: Fixed platforms (e.g., large granite slabs in factories) offer max stability/accuracy but lack mobility. Portable ones (lightweight, foldable designs) suit on - site jobs (like construction surveys) but trade some precision for flexibility. Pick based on task mobility vs. accuracy needs.

Q: Do inspection platforms require the same calibration frequency as measurement platforms?

A: Often yes—both rely on precision. Measurement platforms might need monthly calibration for ultra - precise tasks (e.g., aerospace), while inspection platforms in general manufacturing follow quarterly/annual schedules. Frequency depends on use intensity and industry standards.

Welcome to Storaen (Cangzhou) International Trading Co., a paragon of manufacturing excellence rooted in Botou, China’s casting heartland. We redefine industrial precision through our premium range of cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves—each product a testament to rigorous quality control and engineering mastery.

Strategically located amid Botou’s vibrant ecosystem of raw material suppliers and skilled artisans, we leverage local expertise to deliver unmatched durability and reliability. Our commitment to innovation drives continuous technological advancement, while customer-centric approaches ensure solutions tailored to global industry needs.

Sustainability lies at our core, with eco-friendly practices minimizing our environmental impact. As a trusted partner to industries worldwide, we blend a legacy of craftsmanship with forward-thinking solutions, ready to exceed your expectations in an ever-evolving industrial landscape.

Explore our precision-engineered products at www.strmachinery.com and discover the Storaen difference.

-

thread-plug-gauge-our-promise-of-measurement-excellenceKabarAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyKabarAug.22,2025

-

check-valve-types-for-high-rise-buildingsKabarAug.22,2025

-

water-control-valve-for-irrigation-systemsKabarAug.22,2025

-

gate-valve-with-soft-seal-technologyKabarAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsKabarAug.22,2025

PRODUK sing gegandhengan