Dic . 28, 2024 17:44 Back to list

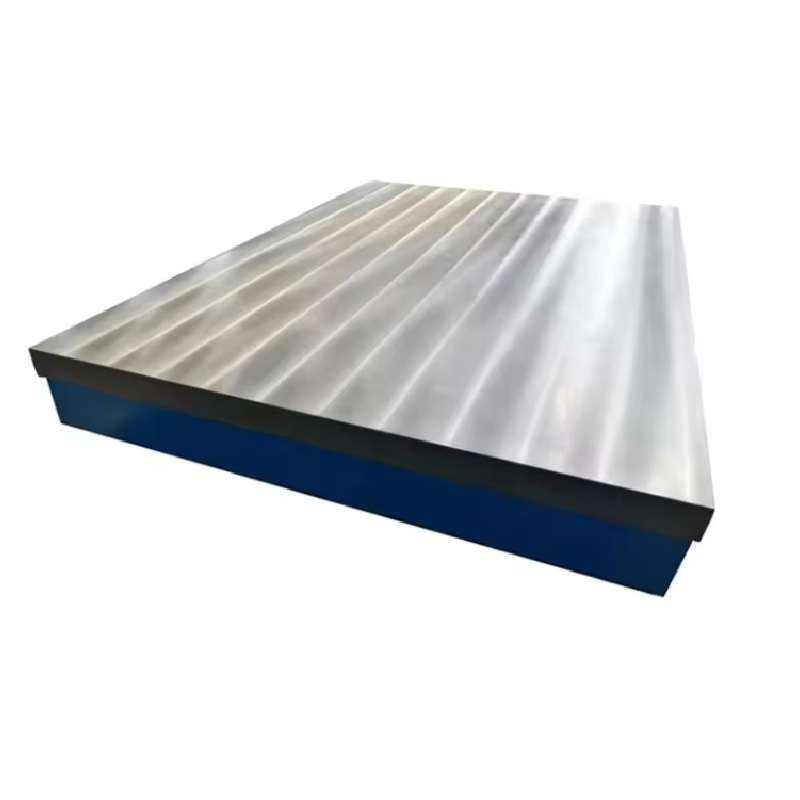

granite inspection surface plate

The Importance of Granite Inspection Surface Plates in Precision Measurement

In the realm of precision measurement and quality control, granite inspection surface plates play an indispensable role. These robust, flat surfaces serve as the foundational workspace for various inspection processes, offering remarkable stability and accuracy that is essential in manufacturing and engineering. This article aims to elaborate on the significance of granite inspection surface plates, their inherent advantages, and their applications in various industries.

Granite, a naturally occurring igneous rock primarily composed of quartz, feldspar, and mica, has established itself as the material of choice for inspection surfaces. The intrinsic properties of granite contribute to its effectiveness; it is dense, non-porous, and has an exceptional ability to withstand wear over time. Unlike other materials, granite does not deform under substantial loads, making it highly reliable for measuring tools such as calipers, micrometers, and gauges.

One of the defining characteristics of granite inspection surfaces is their flatness. A surface plate’s flatness is critical; even minute deviations in the surface can lead to significant measurement inaccuracies. High-precision granite plates are calibrated to a flatness tolerance of just a few microns, ensuring that users can achieve consistent and accurate measurements. This precision is paramount in industries where quality assurance and compliance with stringent standards are vital.

Another notable advantage of granite inspection surface plates is their thermal stability. Unlike metal surfaces, which can expand or contract with temperature fluctuations, granite maintains its dimensional stability across a wide range of temperatures. This stability is particularly advantageous in environments where temperature changes are inevitable, thus preventing measurement errors caused by thermal expansion.

granite inspection surface plate

Furthermore, granite’s resistance to chemicals enhances its appeal for inspection applications. Unlike certain materials that might corrode or degrade upon exposure to harsh substances, granite can withstand chemicals such as oils, solvents, and acids. This characteristic allows for a broad range of applications in various industries, including automotive, aerospace, electronics, and more.

The versatility of granite inspection surface plates extends beyond their durability and stability. They can be used in conjunction with a variety of precision measuring tools, facilitating an array of inspection techniques. Whether inspecting machined components, conducting gauge calibration, or performing dimensional checks, these surface plates provide a solid, reliable base for accurate measurements.

Maintenance of granite inspection surface plates is relatively straightforward. Regular cleaning and the use of appropriate measuring tools are sufficient to maintain their performance over time. Unlike softer materials that may scratch or wear out, granite offers a longevity that justifies its initial investment.

In terms of cost, although granite inspection surface plates may appear to be more expensive than alternatives, their durability and low maintenance costs often lead to a more cost-effective solution in the long run. Investing in a quality granite plate ensures that organizations can achieve high standards of accuracy and efficiency in their quality control processes.

In conclusion, granite inspection surface plates are a cornerstone of precision measurement in various industries. Their flatness, thermal stability, resistance to wear and chemicals, as well as ease of maintenance, make them the ideal choice for quality assurance tasks. As industries continue to prioritize precision and accuracy, the role of granite inspection surface plates will undoubtedly remain significant, ensuring that products meet the highest standards and that companies maintain their competitive edge in the market. For organizations aspiring for excellence, investing in granite inspection surface plates is not just an option but a necessity.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS