Giu . 05, 2025 13:52 Torna alla lista

Cost - Effective Solutions with Pin Gauges

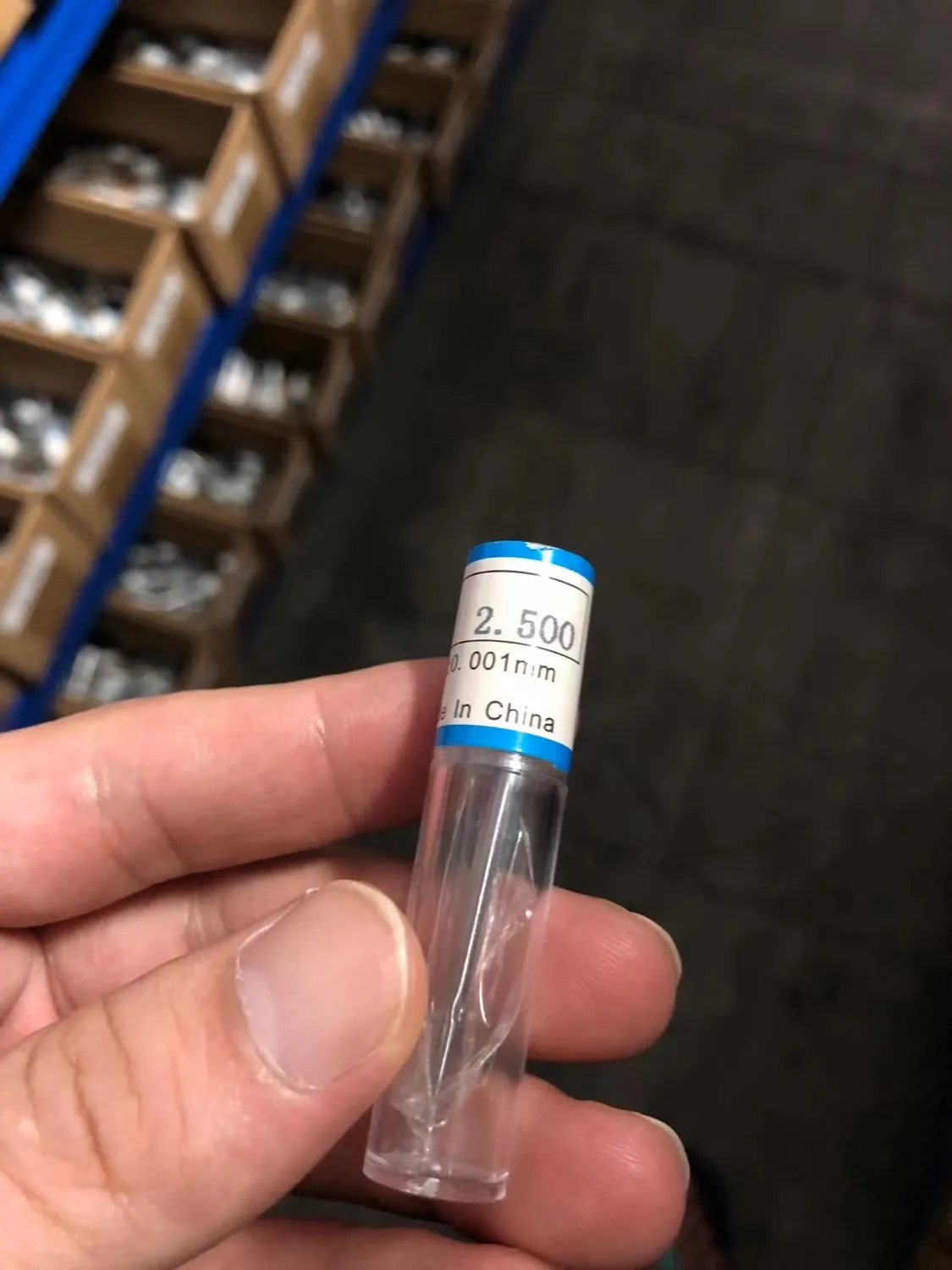

In the intricate landscape of industrial manufacturing and quality control, achieving accurate measurements while managing costs is a constant pursuit. Pin gauges, with their diverse forms such as calibrated pin gauges and go no go pin gauge, offer valuable solutions in this regard. These unassuming yet powerful tools play a crucial role in ensuring product quality, streamlining processes, and ultimately reducing expenses. Understanding how to leverage the unique capabilities of pin gauges, calibrated pin gauges, and go no go pin gauge can unlock significant cost - effective benefits for various industries. From their inherent features to smart usage strategies, exploring the potential of these measuring instruments reveals a world of opportunities for optimizing operations without compromising on precision.

Fundamental Features of Pin Gauges for Cost - Efficiency

Pin gauges possess fundamental features that contribute to cost - efficiency in measurement processes. Their simple and robust design allows for easy handling and long - term durability, reducing the need for frequent replacements. The slender, cylindrical shape of pin gauges enables them to access tight and hard - to - reach areas, facilitating comprehensive inspection of components without the need for complex and costly equipment. For instance, in the production of small mechanical parts with intricate internal geometries, a pin gauge can quickly and accurately assess the dimensions, eliminating the requirement for more expensive and specialized measuring devices. This versatility in application minimizes the investment in multiple measurement tools, directly contributing to cost savings. Additionally, the ease of operation of pin gauges means that minimal training is needed for operators, reducing labor costs associated with extensive training programs.

Precision and Savings with Calibrated Pin Gauges

Calibrated pin gauges offer a combination of precision and cost - saving potential. Through meticulous calibration processes, these gauges ensure highly accurate measurements, which is essential for maintaining product quality. By providing reliable data, calibrated pin gauges prevent the production of defective parts. In manufacturing, even a minor measurement error can lead to a cascade of issues, resulting in wasted materials, rework, and production delays. With calibrated pin gauges, the likelihood of such errors is significantly reduced. This not only saves on the cost of raw materials but also minimizes the time and resources spent on rectifying mistakes. Moreover, the long - term stability of calibrated measurements means that calibrated pin gauges can be used consistently over time without frequent recalibration, further optimizing costs related to instrument maintenance and management.

Strategic Selection and Usage for Cost - Effectiveness

Strategic selection and usage of pin gauges, calibrated pin gauges, and go no go pin gauge are key to achieving cost - effectiveness. Understanding the specific requirements of each measurement task is essential. For basic dimensional checks where a quick pass - fail determination suffices, a go no go pin gauge is the ideal choice. In contrast, for applications demanding high - precision measurements and traceable data, calibrated pin gauges are more suitable. By choosing the right tool for the job, unnecessary expenses associated with over - specifying or under - specifying measurement instruments can be avoided. Additionally, proper maintenance and storage of these gauges extend their lifespan. Regular cleaning, protection from environmental factors, and correct handling ensure that pin gauges remain in optimal condition, reducing the frequency of replacements and associated costs.

Integration into Processes for Overall Cost Reduction

Integrating pin gauges, calibrated pin gauges, and go no go pin gauge into existing manufacturing and quality control processes can lead to significant overall cost reduction. By incorporating these tools at key points in the production line, potential issues can be identified early. For example, using a go no go pin gauge during the initial stages of part production can quickly flag components that are out of tolerance, preventing them from proceeding further in the production process and incurring additional costs. Calibrated pin gauges can be used for in - process verification to ensure that parts are being manufactured to the correct specifications, reducing the likelihood of costly rework at later stages. This proactive approach to measurement and quality control, enabled by these pin gauges, helps streamline operations, minimize waste, and ultimately achieve cost - effective production.

Pin Gauges FAQS

How do pin gauges contribute to cost - savings in manufacturing?

Pin gauges contribute to cost - savings in multiple ways. Their simple and durable design reduces the need for frequent replacements, cutting down on equipment costs. Their ability to access hard - to - reach areas eliminates the requirement for more expensive specialized measuring devices. The ease of operation of pin gauges means minimal training for operators, saving on labor costs. By enabling comprehensive and accurate inspection, they prevent the production of defective parts, avoiding the waste of raw materials, rework, and production delays, all of which are significant cost factors in manufacturing.

What advantages do calibrated pin gauges offer for cost - effective quality control?

Calibrated pin gauges provide several advantages for cost - effective quality control. Their high - precision measurements ensure that parts are manufactured to the correct specifications, preventing the production of defective items and the associated costs of rework, scrap, and lost production time. The reliable data they provide helps maintain consistent product quality, reducing the risk of costly product recalls or customer complaints. Additionally, the long - term stability of calibrated measurements means less frequent recalibration is needed, optimizing costs related to instrument maintenance and management, making them a valuable asset for maintaining quality while controlling expenses.

In what situations is a go no go pin gauge the most cost - effective choice?

A go no go pin gauge is the most cost - effective choice in high - volume production environments where rapid inspection is crucial. When the goal is to quickly determine whether a part’s dimension falls within the acceptable tolerance range without the need for detailed measurements, this type of gauge shines. It allows operators to swiftly sort parts into acceptable and non - acceptable categories, increasing production throughput and reducing inspection time. This leads to less idle time for machinery and labor, optimizing resource utilization. Its straightforward operation also reduces the risk of human error during inspection, avoiding costs associated with misclassified parts and re - evaluation, making it an ideal option for cost - efficient quality control in such situations.

How can proper selection and usage of pin gauges enhance cost - effectiveness?

Proper selection and usage of pin gauges enhance cost - effectiveness by ensuring that the right tool is used for each measurement task. Choosing a go no go pin gauge for basic pass - fail checks and calibrated pin gauges for high - precision measurements avoids over - or under - specifying measurement instruments, saving on unnecessary expenses. Additionally, following best practices for maintenance and storage, such as regular cleaning and correct handling, extends the lifespan of pin gauges, reducing replacement costs. By integrating these gauges strategically into production processes, potential issues can be identified early, preventing costly rework and production delays, thus optimizing overall operational costs.

What role do pin gauges play in reducing overall production costs?

Pin gauges, including calibrated pin gauges and go no go pin gauge, play a vital role in reducing overall production costs. They enable accurate and efficient inspection, preventing the production of defective parts and the associated waste of materials, time, and labor. Go no go pin gauges streamline the inspection process in high - volume production, increasing throughput and reducing idle time. Calibrated pin gauges ensure precision in measurements, maintaining product quality and avoiding costly quality - related issues. By being integrated into production processes at key points, they help identify and address problems early, minimizing rework and production delays, ultimately contributing to significant cost savings across the entire production cycle.

-

Why the Right Angle Ruler Reigns in MetalworkingNotiziaJul.21,2025

-

The Enduring Allure of Granite Boxes in Modern InteriorsNotiziaJul.21,2025

-

The Digital Gauging Revolution: Reshaping Thread Rings Inspection's FutureNotiziaJul.21,2025

-

How Modern Inspection Platforms Transcend Surface MeasurementNotiziaJul.21,2025

-

How Customization Drives Wholesale Success in Parallel RulersNotiziaJul.21,2025

-

Fortifying Permanent Steel Ground Anchors Against Corrosion's OnslaughtNotiziaJul.21,2025

Prodotti correlati