okt . 05, 2024 19:21 Back to list

Calibrating Spline Gauges for Accurate Measurement Applications

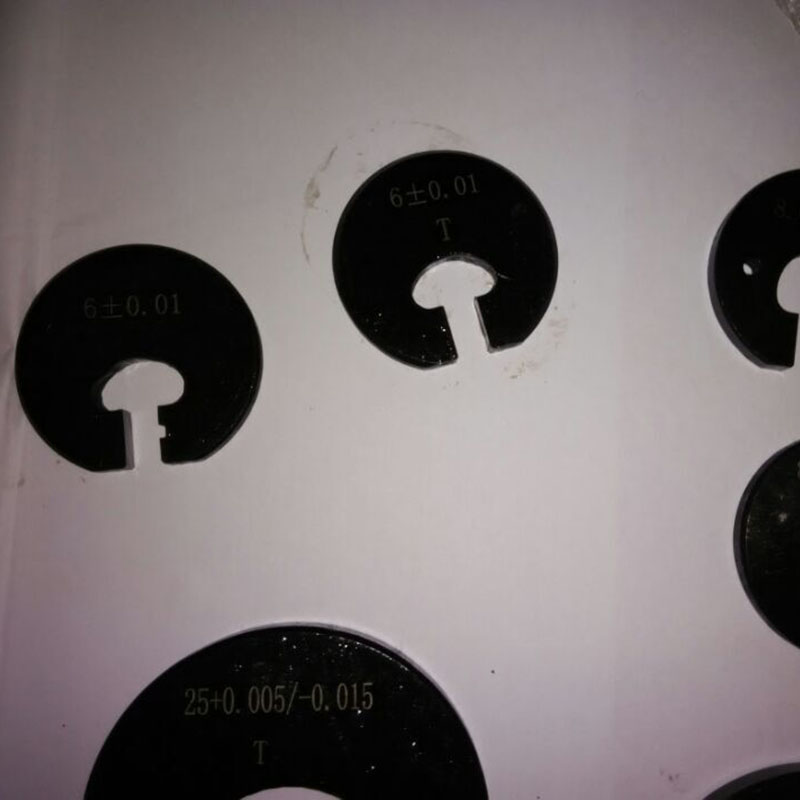

Understanding Spline Gage Calibration Ensuring Precision in Measurements

Spline gages are essential tools in the realm of precision engineering and manufacturing. Often used to measure complex geometries and contours, these gages ensure that components meet stringent specifications and fit together correctly. However, the accuracy of measurements obtained from spline gages heavily relies on proper calibration. This article delves into the significance of spline gage calibration, the process involved, and its importance in various industries.

Importance of Calibration

Calibration is the process of adjusting and verifying the accuracy of measurement instruments. For spline gages, calibration ensures that the measurements taken reflect the true dimensions of the part being assessed. Without proper calibration, there exists a risk of accumulating errors during the manufacturing process, potentially leading to defective products and costly rework.

In industries such as aerospace, automotive, and manufacturing, the precision of each component is critical. For instance, in aerospace engineering, even a minor deviation in measurements can lead to severe safety risks. Therefore, regular calibration of spline gages is not just a best practice but a necessary measure to uphold industry standards and ensure quality control.

The Calibration Process

Calibration of spline gages involves a series of well-defined steps

1. Preparation Before calibration, it’s important to gather all necessary equipment and tools, including standard gages with known dimensions, calibration software, and environmental controls to minimize temperature and humidity fluctuations.

spline gage calibration

2. Initial Verification The first step is to perform an initial check on the spline gage by measuring it against known standards. This step helps identify any significant discrepancies that need to be addressed during the calibration process.

3. Adjustment If any errors are detected, the spline gage must be adjusted accordingly. This adjustment may involve mechanical recalibration, software updates, or sensor realignment to ensure that the gage operates within specified tolerances.

4. Re-testing After adjustments are made, the spline gage must be re-tested against the standard measurements. This verification step ensures that the gage now provides accurate readings.

5. Documentation Finally, detailed records of the calibration process must be maintained. This documentation should include the date of calibration, the individual conducting the calibration, the tools used, and the results of the tests. Such records are vital for traceability and compliance with industry regulations.

Benefits of Regular Calibration

Regular calibration of spline gages offers numerous benefits. Firstly, it enhances the reliability and accuracy of measurements, ultimately improving product quality. Secondly, it helps in reducing waste and minimizing the costs associated with defective parts. Finally, maintaining a robust calibration schedule promotes compliance with regulatory standards and builds trust with clients and stakeholders.

Conclusion

In conclusion, spline gage calibration is a critical aspect of precision manufacturing that cannot be overlooked. By ensuring that these tools are accurately calibrated, companies not only enhance the quality of their products but also foster a culture of excellence and safety within their operations. As industries continue to evolve and demand higher standards, the role of proper calibration in maintaining measurement integrity becomes increasingly vital. Investing in regular calibration protocols is an investment in quality, reliability, and long-term success in today’s competitive landscape.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS