júl . 10, 2025 09:48 Aftur á lista

Precision Pin Gauge Delivers Reliable Inspection Results

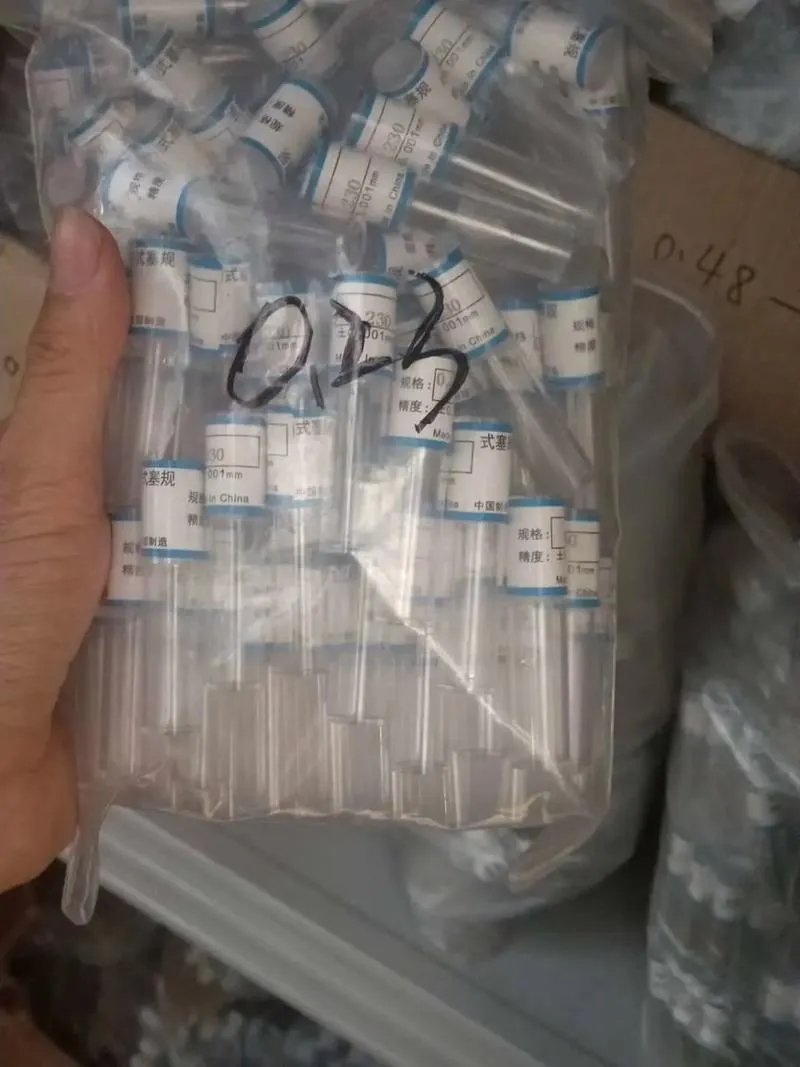

In the exacting realm of industrial quality control, the reliability of inspection tools can make or break the success of a manufacturing operation. Pin gauge products from Storaen (Cangzhou) International Trading Co. are engineered to meet the highest standards of precision, ensuring consistent and trustworthy inspection results. Our comprehensive range, including machinist gauge pins models, combines advanced manufacturing techniques, premium materials, and meticulous craftsmanship to provide industries with the essential tools for accurate dimensional inspection.

Storaen (Cangzhou) International Trading Co.’s Dedication to Precision Pin Gauge Manufacturing

- Based in Botou, China, Storaen (Cangzhou) International Trading Co. has long been a leader in producing top-tier industrial measurement tools.

- When it comes to pin gaugemanufacturing, our company’s dedication to precision remains unwavering.

- We employ a team of seasoned engineers who leverage state-of-the-art technology and strict quality control processes.

- Every step is carefully monitored, from the selection of high-grade materials like GCr15 bearing steel to the final inspection of each finished product.

- This commitment ensures our pin gaugeofferings consistently deliver the reliability required for critical inspection tasks across diverse industries.

The Design and Engineering Behind Reliable Pin Gauge Performance

The reliability of our pin gauge products stems from their intelligent design and robust engineering. Crafted from GCr15 bearing steel, these gauges undergo a meticulous heat-treatment process that enhances their hardness and dimensional stability. The surface of machinist gauge pins is precision-ground and lapped to achieve an ultra-smooth finish, reducing friction during measurements and minimizing wear. For thread pin gauge models, the threads are precisely formed to match industry standards, enabling accurate “go/no-go” assessments of internal threads. This combination of material quality, design features, and manufacturing precision results in pin gauges that can be relied upon to provide consistent and accurate inspection outcomes.

Applications of Machinist Gauge Pins in Critical Inspection Processes

- Machinist gauge pinsfrom Storaen (Cangzhou) International Trading Co. play a vital role in various critical inspection processes.

- In the automotive industry, they verify the diameter of engine components to ensure proper fit and function.

- Aerospace manufacturers rely on these gauges to inspect aircraft parts with extreme precision, as even minor deviations can have significant consequences.

- In general machining operations, machinist gauge pinsensure holes and slots are machined to correct specifications, maintaining the quality and integrity of final products.

- Their reliability makes them an indispensable tool for any inspection task requiring accuracy.

Thread Pin Gauge: Ensuring Accuracy in Thread Inspection

Our thread pin gauge models are specifically designed to excel in thread inspection, providing accurate and reliable results. Whether inspecting the threads of nuts, bolts, or other threaded components, these gauges offer a precise “go/no-go” evaluation. The carefully crafted threads on the thread pin gauge match the pitch and profile of the threads being inspected, allowing for a snug fit. This enables inspectors to quickly and accurately determine if a thread meets the required standards. By using our thread pin gauge, manufacturers can prevent costly assembly issues caused by incorrect thread dimensions and ensure the overall quality of their products.

Pin Gauge FAQS

How do pin gauges ensure reliable inspection results?

Storaen (Cangzhou) International Trading Co.’s pin gauge ensures reliable inspection results through a combination of factors. The use of high-grade materials like GCr15 bearing steel, along with heat treatment, provides excellent hardness and stability. Precision-ground and lapped surfaces reduce measurement errors caused by friction. For thread pin gauge models, the accurate thread formation allows for precise evaluations. These design and manufacturing features work together to ensure that each measurement is consistent and trustworthy, delivering reliable inspection outcomes.

Can machinist gauge pins be used for different types of materials?

Yes, our machinist gauge pins are suitable for use with a variety of materials. The robust construction and durable materials used in their manufacture enable them to withstand the rigors of measuring different substances, from soft metals to hard plastics. Their precision-ground surfaces ensure smooth insertion and removal, regardless of the material’s texture. Whether in metalworking, plastic molding, or other manufacturing processes, machinist gauge pins can accurately measure dimensions and contribute to reliable inspection results across diverse materials.

What maintenance is required for thread pin gauges?

Maintenance for thread pin gauges is relatively straightforward. Regularly clean the gauges with a soft brush or cloth to remove debris, metal shavings, and any contaminants that could affect accuracy. After use, apply a light coating of lubricant to prevent corrosion and keep the threads in good condition. Store the gauges in a protective case to avoid damage. Periodically check for any signs of wear or damage, and if necessary, have the gauges calibrated by professionals. Following these steps will help maintain the reliability of thread pin gauges over time.

Are there different sizes available for precision pin gauges?

Yes, Storaen (Cangzhou) International Trading Co. offers a wide range of sizes for our precision pin gauges. We understand that different inspection tasks require gauges of varying diameters. Our comprehensive selection includes a diverse array of sizes for pin gauge models. Additionally, we can provide customized size options to meet specific customer requirements, ensuring that there is a suitable precision pin gauge for every inspection application, no matter how unique the measurement needs may be.

How do Storaen’s pin gauges compare in terms of accuracy to other brands?

Storaen (Cangzhou) International Trading Co.’s pin gauges excel in accuracy compared to many other brands. Our strict quality control processes, from material selection to final inspection, ensure that each gauge meets tight tolerances. The precision-ground and lapped surfaces of machinist gauge pins and the accurate thread formation of thread pin gauge models contribute to highly accurate measurements. Unlike some competitors, our gauges maintain their accuracy over extended periods of use, providing industries with a reliable and consistent tool for inspection tasks where precision is paramount.

-

Thread Plug Gauge Our Promise of Measurement ExcellenceFréttirAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyFréttirAug.22,2025

-

Check Valve Types for High Rise BuildingsFréttirAug.22,2025

-

Water Control Valve for Irrigation SystemsFréttirAug.22,2025

-

Gate Valve with Soft Seal TechnologyFréttirAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsFréttirAug.22,2025

Skyldar vörur