des . 12, 2024 10:18 Back to list

globe valve a105

The A105 Globe Valve A Robust Solution for Fluid Control

Globe valves are essential components in various industrial applications, including oil and gas, water treatment, power generation, and chemical processing. Among the many types of globe valves, the A105 globe valve stands out for its durability and efficiency. This article delves into the features, applications, and advantages of A105 globe valves, providing a comprehensive overview of their role in fluid control systems.

Understanding A105 Material

The term A105 refers to a specific carbon steel material that conforms to the ASTM A105 standard. This standard specifies the chemical composition and mechanical properties of carbon steel, which is utilized in the manufacturing of forged piping components. A105 is known for its strength and versatility, making it an excellent choice for high-pressure and high-temperature applications. The material's excellent weldability and machinability further enhance its usability across a range of industrial sectors.

Design Features

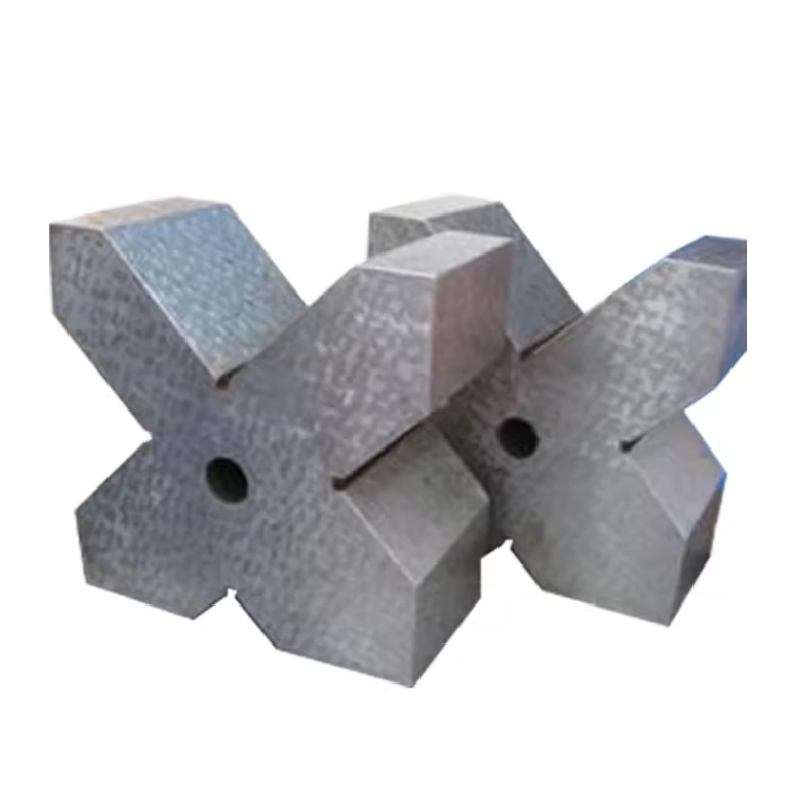

The A105 globe valve is characterized by its unique design, which allows for efficient throttling of fluid flow and tight sealing. The valve consists of a spherical body with an internal baffle that directs the flow of fluid, creating a pressure drop. This design allows operators to control the flow rate effectively, making it suitable for applications where precise regulation is essential.

Key design features of A105 globe valves include

1. Body and Bonnet Construction The A105 globe valve is typically constructed with a forged body and bonnet, ensuring strength and the ability to withstand high-pressure environments. 2. Sealing Mechanism The valve is equipped with a resilient sealing mechanism that provides excellent leak-tight performance. This is critical in preventing fluid loss and ensuring safety in industrial applications.

3. Flow Direction Unlike other valve designs, globe valves have a linear flow pattern, which reduces turbulence and pressure loss. This characteristic is particularly beneficial in applications requiring consistent flow rates.

4. Size and End Connections A105 globe valves are available in various sizes, typically ranging from ½ inch to 12 inches, with options for threaded, flanged, or welded end connections, making them adaptable for various piping systems.

Applications of A105 Globe Valves

A105 globe valves find applications across numerous industries, including

globe valve a105

1. Oil and Gas In the oil and gas industry, A105 globe valves are used for controlling the flow of crude oil, natural gas, and various refined products. Their robust construction enables them to handle the high pressures and harsh conditions often encountered in this sector.

2. Power Generation Globally, many power plants utilize A105 globe valves in steam and water lines. They are instrumental in regulating steam flow and preventing backflow, ensuring efficient power generation and operational safety.

3. Chemical Processing The chemical industry relies on A105 globe valves for managing corrosive and high-temperature fluids. Their durable design aids in maintaining process integrity and reducing downtime.

4. Water Treatment In municipal and industrial water treatment facilities, A105 globe valves are employed in various applications, including flow regulation, isolation, and filtration processes.

Advantages of A105 Globe Valves

The use of A105 globe valves comes with several advantages

1. Durability Made from high-quality carbon steel, A105 globe valves offer exceptional durability, ensuring long lifespan and reliable performance even in demanding environments.

2. Efficiency The effective throttling capabilities of globe valves facilitate precise control of fluid flow, enhancing operational efficiency and minimizing wastage.

3. Versatility A105 globe valves can be utilized in diverse applications, making them a versatile choice for engineers and operators.

4. Cost-effective Given their longevity and performance, A105 globe valves provide a cost-effective solution in the long run, reducing the need for frequent replacements and maintenance.

Conclusion

In conclusion, the A105 globe valve is an exemplary choice for industries requiring reliable fluid control. Its robust construction, efficient design, and versatility make it a preferred option for applications in the oil and gas, power generation, chemical processing, and water treatment sectors. As industries evolve and demand for efficient flow control systems increases, the A105 globe valve will undoubtedly play a pivotal role in ensuring operational excellence.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS