júl . 29, 2024 04:04 Back to list

Enhancing Precision in Measurements with High-Quality Stone Surface Plates for Industrial Applications

The Significance of Stone Surface Plates in Precision Engineering

In the realm of precision engineering and metrology, stone surface plates play a pivotal role in ensuring accuracy and reliability in measurements and product fabrication. Typically constructed from high-quality granite, these flat plates serve as an essential reference tool in various industries, including manufacturing, aerospace, automotive, and quality control laboratories. This article explores the significance, characteristics, and applications of stone surface plates in a professional environment.

What Are Stone Surface Plates?

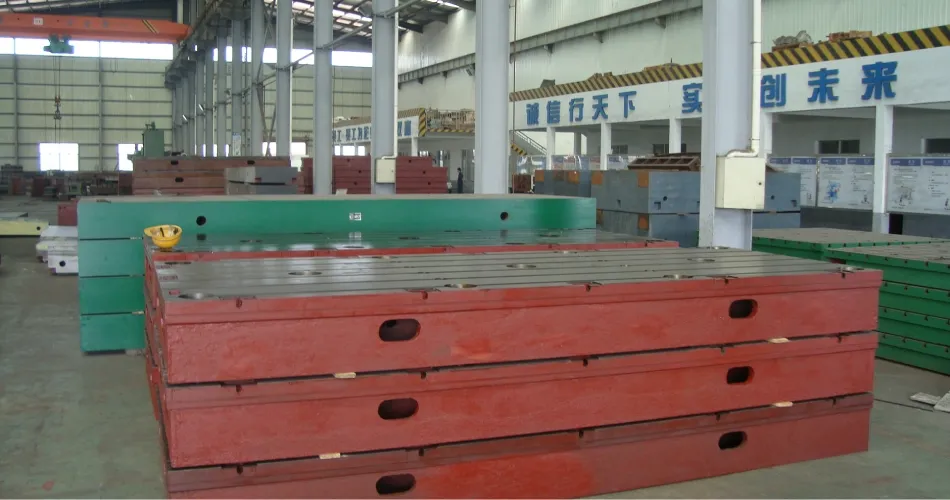

Stone surface plates are large, flat slabs made from fine-grained granite, chosen for their superior stability and rigidity. The natural properties of granite, including its ability to resist wear and deformation, make it an ideal material for producing a surface that can withstand the rigors of mechanical inspection and measurement. The plates are carefully crafted to attain a high degree of flatness, ensuring that they serve as an accurate reference surface.

Importance in Precision Measurement

The primary purpose of stone surface plates is to provide a stable and flat surface for various measurement and inspection tasks. In the world of precision engineering, even the smallest deviation can lead to significant errors in the final product. By utilizing a granite surface plate, engineers and technicians can ensure that their measuring instruments, such as height gauges, dial indicators, and coordinate measuring machines (CMMs), provide precise and repeatable measurements.

Moreover, stone surface plates are often used for aligning and supporting machined parts during the fabrication process. The flat surface allows for consistent contact points, which are crucial when performing tasks like machining, grinding, or welding. This ensures that machined components meet exact specifications before moving to the next stage of production.

Characteristics of Stone Surface Plates

The effectiveness of stone surface plates stems from several key characteristics

1. Flatness and Accuracy The definition of a good surface plate is its flatness. High-quality granite plates achieve tolerances that can be as precise as a few microns, making them indispensable in precision engineering.

stone surface plate

2. Durability Granite is resistant to scratching and wear, allowing surface plates to maintain their flatness over time under continuous use.

3. Thermal Stability Granite's low thermal expansion rate makes it an ideal choice for environments where temperature variation can affect measurement accuracy.

4. Non-magnetic Properties Unlike some metals, granite does not have magnetic properties, ensuring that it won’t interfere with sensitive measuring instruments.

5. Cost-Effectiveness While they are a significant investment, granite surface plates offer longevity and reliability, resulting in reduced costs over time when compared to more fragile materials.

Applications of Stone Surface Plates

The applications of stone surface plates are widespread. They are commonly found in

- Quality Control In factories, surface plates serve as the basis for quality control and assurance processes, providing a stable reference for checking the dimensions of manufactured parts. - Calibration Instrument calibration frequently relies on granite surface plates to ensure that measuring tools remain accurate over time. - Tool Setup Machinists often use surface plates to set up tools and fixtures with utmost precision, facilitating accurate machining operations. - Research and Development Surface plates are crucial in R&D labs for experimental setups that require high levels of accuracy and repeatability.

Conclusion

In summary, stone surface plates are indispensable tools in precision engineering and metrology. Their unmatched flatness, durability, and stability make them essential for ensuring accuracy in measurements and maintaining the integrity of manufacturing processes. Investing in high-quality stone surface plates can significantly enhance the precision and quality of engineering projects, ensuring that industries continue to produce high-caliber products in an increasingly competitive market.

-

Smart Monitoring Integration with Modern Gate Valve TypesNewsJun.16,2025

-

Innovative Metal Mesh Strainer Designs for Modern Minimalist KitchensNewsJun.16,2025

-

Impact of Control Valve Maintenance on Pipeline SafetyNewsJun.16,2025

-

Essential Maintenance Tips for Trunnion Ball Valves TypesNewsJun.16,2025

-

Cost-Benefit Analysis of Common Check Valve TypesNewsJun.16,2025

-

Bidirectional Flow Challenges in Globe Valve SystemsNewsJun.16,2025

Related PRODUCTS