nóv . 30, 2024 06:48 Back to list

Understanding the Functionality of Check Valve Discs in Fluid Systems

Understanding Check Valve Discs Importance, Functionality, and Applications

In the realm of fluid dynamics, check valves play a pivotal role in ensuring the smooth and efficient operation of various systems. Among the essential components of a check valve is the check valve disc, a critical element that prevents backflow and maintains the integrity of fluid flow. This article delves into the significance, functionality, and applications of check valve discs, highlighting their crucial role in various industries.

What is a Check Valve?

A check valve, also known as a non-return valve, is a mechanical device that permits fluid (liquid or gas) to flow in one direction only. This functionality is achieved through the use of a movable component known as the disc. The disc is designed to close automatically when there is a reversal of flow, thereby preventing backflow that could potentially damage equipment or disrupt processes.

The Anatomy of a Check Valve Disc

The check valve disc can take various forms, such as a swivel disc, lift disc, or piston-type disc, determined by the application requirements and the design of the valve. Typically, check valve discs are crafted from durable materials like stainless steel, brass, or polymer composites, chosen for their resistance to corrosion and wear. This durability is essential for maintaining functionality over time, especially in demanding environments.

The Functionality of Check Valve Discs

The primary role of the check valve disc is to act as a barrier to reverse flow. When fluid flows in the designated forward direction, the disc opens, allowing for smooth passage. However, in instances of backflow or a drop in pressure, gravitational force or fluid dynamics act upon the disc, prompting it to close tightly against the valve seat. This swift closure is crucial to safeguarding systems from potential damage caused by fluid surges, which could lead to pump failure, piping leaks, or contamination.

Applications Across Industries

check valve disc

Check valve discs are employed in a plethora of applications across various industries, including

1. Water and Wastewater Management In facilities dealing with municipal water supply and sewage treatment, check valves prevent the backflow of contaminated water, ensuring that clean supply lines remain untainted.

2. Oil and Gas Industry The extraction and distribution of petroleum products utilize check valves to maintain directional flow and protect pipeline integrity, reducing the risks associated with leaks or spills.

3. Food and Beverage Processing In this sector, check valve discs help maintain hygiene by preventing cross-contamination during fluid transfer processes, ensuring that consumables remain safe for consumption.

4. Chemical Manufacturing The handling of corrosive and reactive chemicals demands rigorous safety measures; check valve discs provide essential backflow prevention in these systems, helping to avert dangerous reactions.

5. Heating and Cooling Systems Check valves are often integrated into HVAC systems, where their discs protect against reverse flow that can disrupt temperature regulation and efficiency.

Conclusion

Check valve discs may appear to be simple components, but their role is vital in controlling fluid dynamics across various systems. By preventing backflow, these discs maintain operational integrity, protect equipment, and enhance safety in numerous applications. Understanding the importance of check valve discs not only underscores their essential function but also highlights the need for regular maintenance and inspection to ensure they perform optimally. As industries continue to evolve and adopt more sophisticated fluid management systems, the significance of reliable check valve discs will undoubtedly remain paramount.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

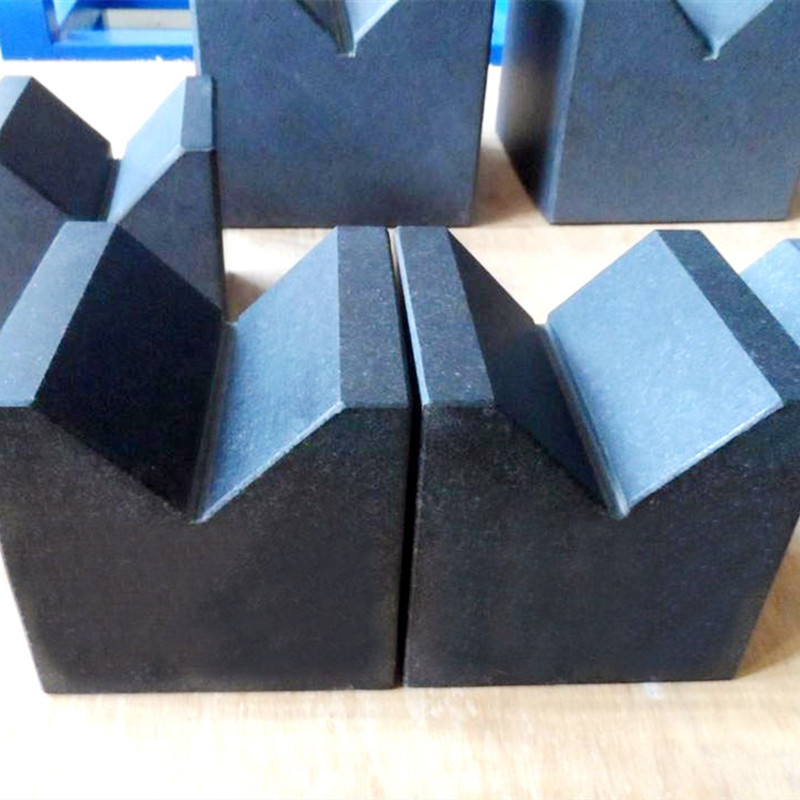

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS