des . 25, 2024 15:10 Back to list

Generating a Similar Based on c gauge in Under 15 Words

Understanding C Gauge A Comprehensive Overview

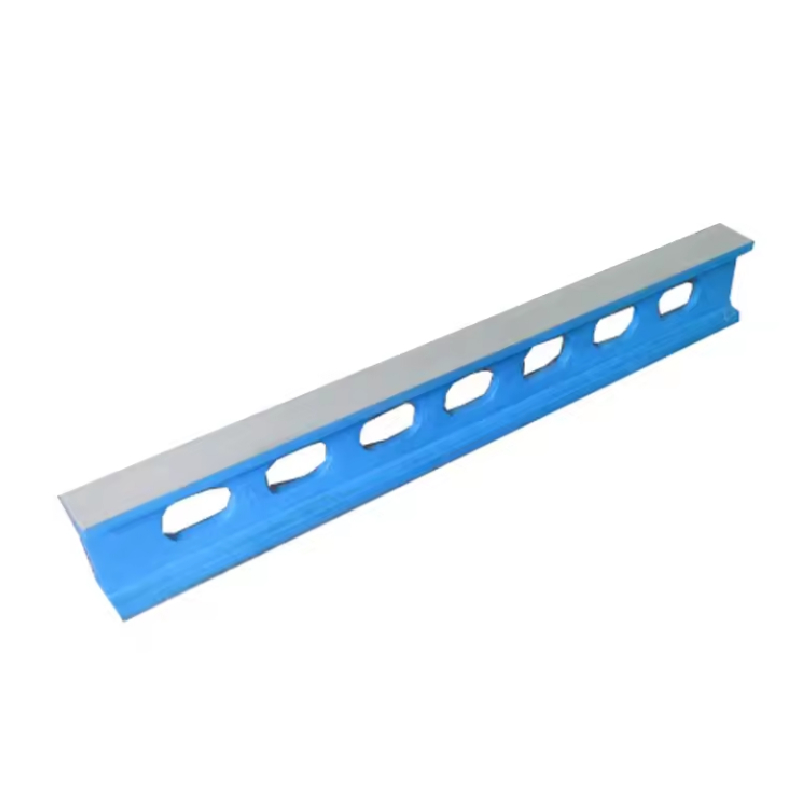

The term C gauge might seem ambiguous at first glance, but it actually represents a crucial concept in various industries, predominantly in the fields of engineering, construction, and manufacturing. Gauge refers to the measurement or thickness of material, often seen in metals like steel or aluminum. Understanding this concept requires familiarity with the measuring system employed, how it is used, and its implications in practical applications.

What is Gauge?

At its core, gauge is a numerical system that describes the thickness or diameter of a material. In the context of metals, a higher gauge number corresponds to a thinner sheet, whereas a lower gauge number indicates a thicker sheet. This may seem counterintuitive, but it's a standardized way of measuring that has evolved over time.

The most common systems for measuring gauge are the American Wire Gauge (AWG) and the Standard Wire Gauge (SWG). Each system has its own scale and is used for different materials. In the construction and manufacturing sectors, gauge measures various products like sheet metal, wires, and other structural components.

Significance of C Gauge in Engineering

In engineering applications, the gauge of materials used is of paramount importance. The choice of gauge can directly influence the strength, durability, and overall performance of a structure or component. For example, in automotive manufacturing, the gauge of steel used for body panels can affect weight, safety, and fuel efficiency. Engineers must carefully consider the gauge based on the intended application, whether it’s for structural integrity or aesthetic purposes.

Moreover, C gauge can also refer to specific requirements in building codes or regulations that dictate minimum material thickness for safety and functionality

. For instance, in construction, building codes might specify minimum gauge for roofing materials or walls to ensure sufficient strength against environmental factors like wind or snow loads.c gauge

Applications in Different Industries

C gauge finds its application in a wide range of industries. In construction, for example, the gauge of metal roofing and siding is crucial for durability and weather resistance. Thicker gauges provide better support and can withstand harsh conditions more effectively, while thinner gauges might be more economical and lighter but may require additional support structures.

In the manufacturing industry, understanding gauge is essential for the production of various components that meet strict quality standards. For instance, in electrical applications, wires of different gauges are chosen based on the required current capacity. Using the wrong gauge can lead to overheating or insufficient power delivery, resulting in failure of the electrical system.

Impact on Cost and Efficiency

The gauge of materials used in production not only affects quality but also influences costs. Thicker materials generally cost more, both in terms of raw material expenses and in terms of processing and transportation. This necessitates a careful balance between cost, performance, and safety needs. Using the correct gauge can optimize manufacturing processes, enhance product performance, and ultimately lead to cost savings in the long run.

Conclusion

In summary, understanding C gauge is vital for professionals working in engineering, construction, and manufacturing. The gauge determines the properties of materials used in various applications and affects the overall efficiency, strength, and functionality of products and structures. By making informed choices about material gauge, engineers and manufacturers can enhance performance and safety, ultimately leading to greater success in their respective fields. As technology continues to advance, the refinement of measurement techniques and standards related to gauge will remain an essential focus, ensuring that industries can continue to innovate while maintaining high safety and performance standards.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS