nóv . 09, 2024 00:12 Back to list

Understanding the Importance and Use of Calibrated Pin Gauges in Precision Measurement

Understanding Calibrated Pin Gauges Importance and Applications

Calibrated pin gauges are essential tools in the realm of precision measurement and quality control across various industries. They are used primarily for verifying hole diameters and ensuring that components meet specific design tolerances. This article will delve into the significance of calibrated pin gauges, their applications, and why they are indispensable in manufacturing and engineering.

What are Calibrated Pin Gauges?

Calibrated pin gauges are cylindrical rods with precise diameters that are manufactured according to specific standards. These pins serve as go/no-go gauges, allowing engineers and quality control inspectors to assess whether a particular hole or feature falls within acceptable tolerances. The term calibrated indicates that these pins have undergone rigorous testing and certification to ensure their accuracy and reliability.

The Principle of Operation

The operation of calibrated pin gauges is straightforward yet critical. To evaluate a hole's diameter, the pin gauge is inserted into the hole. If the pin fits snugly, it indicates that the hole is larger than or equal to the pin's diameter; if it does not fit, it shows that the hole is smaller. This binary assessment aids in maintaining quality control during manufacturing processes.

Types of Calibrated Pin Gauges

1. Go Gauges These are designed to confirm that the hole diameter is not less than a specified size. If the go gauge fits, the dimension is acceptable.

2. No-Go Gauges These check that the hole doesn't exceed a certain diameter. If the no-go gauge fits, the hole is deemed too large and unacceptable.

Pin gauges can come in sets, with multiple gauges of varying diameters, allowing for a range of measurements. Additionally, they can be made from different materials, including steel, stainless steel, and other alloys, depending on the application's demands.

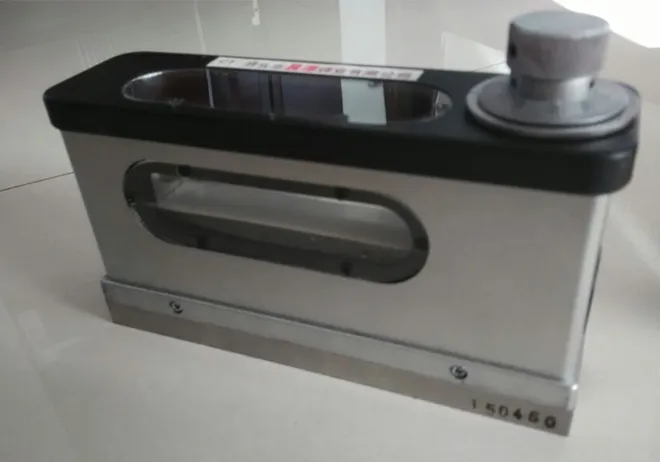

calibrated pin gauges

Importance in Quality Assurance

The significance of calibrated pin gauges in quality assurance cannot be overstated. Industries such as aerospace, automotive, and medical device manufacturing rely on these tools to ensure component interoperability, safety, and functionality. A minuscule deviation in hole diameter can lead to significant implications, such as mechanical failures or compromised product integrity.

Using calibrated pin gauges enhances production efficiency, reduces waste, and facilitates compliance with stringent regulatory standards. Regular use of these gauges in the production line ensures that manufacturing processes remain within specified tolerances, helping companies avoid costly reworks and non-conformities.

Applications of Calibrated Pin Gauges

1. Manufacturing In the manufacturing sector, pin gauges are used in various processes, including the production of gears, shafts, and other cylindrical components, to ensure they meet design specifications.

2. Assembly During assembly operations, calibrated pin gauges help confirm that parts fit together correctly, which is vital for the overall functionality of mechanical systems.

3. Quality Control Inspection labs employ pin gauges to check the dimensions of machined parts before and after production. This process is crucial for maintaining quality standards and regulatory compliance.

4. Research and Development In R&D environments, calibrated pin gauges assist in testing prototypes, ensuring that new designs comply with intended specifications.

Conclusion

Calibrated pin gauges play a pivotal role in the accuracy and reliability of measurements in countless industries. Their ability to provide quick and definitive assessments of hole diameters ensures that components meet necessary standards, thereby enhancing production efficiency and maintaining quality assurance. As technological advancements continue, the significance of precise measurement tools like calibrated pin gauges will only become more pronounced, solidifying their position as indispensable assets in modern manufacturing and engineering.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS