nóv . 10, 2024 19:50 Back to list

Cost of 2 Inch Globe Valve and Related Pricing Information

Understanding the Price of 2-Inch Globe Valves Factors, Trends, and Insights

Globe valves are critical components in various piping systems, providing controlled flow and isolation. Among the different sizes available, the 2-inch globe valve is particularly popular due to its balance between size and functionality. Understanding the pricing of these valves requires a careful analysis of several factors that influence their cost in the market.

What is a Globe Valve?

A globe valve is designed to regulate flow in a pipeline. Unlike gate valves that function as on/off switches, globe valves are capable of throttling flow, making them suitable for applications where precise control is necessary. Their unique design includes a spherical body, which allows for a smooth flow path, minimizing turbulence.

Factors Influencing the Price of 2-Inch Globe Valves

1. Material Composition The material from which a valve is made plays a significant role in determining its price. Common materials include stainless steel, brass, cast iron, and PVC. Stainless steel valves are typically more expensive due to their corrosion resistance and durability, making them suitable for demanding environments. Brass and cast iron are often more affordable but may not offer the same longevity.

2. End Connections The type of end connections (threaded, flanged, or soldered) can significantly affect cost. Flanged connections are usually more expensive due to the additional machining and material required. In contrast, threaded valves are generally more affordable, appealing for applications where cost is a primary concern.

3. Design and Specifications Within the category of 2-inch globe valves, numerous designs and specifications are available. Features like temperature and pressure ratings, as well as specialized designs for specific applications (e.g., high-temperature or high-pressure systems), can lead to variances in pricing. Custom-made valves tend to be more expensive due to the additional engineering and manufacturing processes involved.

4. Brand and Manufacturer Pricing can also vary based on the brand or manufacturer’s reputation. Established brands that guarantee quality and provide extensive warranties may charge higher prices. Conversely, lesser-known manufacturers may offer more competitive pricing to attract customers, albeit with varying levels of quality assurance.

2 inch globe valve price

5. Market Demand and Supply Like any product, the law of supply and demand can influence pricing. During periods of high construction activity or industrial expansion, the demand for valves increases, which can drive prices up. Conversely, during economic downturns, prices may stabilize or decline due to reduced demand.

6. Geographical Location Prices may vary significantly based on geographical location due to transportation costs, local demand, and availability of materials. Regions with strong industrial bases may experience higher demand for valves, affecting pricing structures.

7. Regulatory Compliance Certain industries require valves that meet specific regulatory standards. Valves that comply with such standards often come at a premium due to the additional testing and certification processes involved.

Current Pricing Trends

As of 2023, the price of a 2-inch globe valve typically ranges from approximately $50 to $200, depending on the factors discussed above. The cost for standard brass or PVC valves stands at the lower end of the spectrum, while high-performance or specialty stainless steel options may push prices towards the higher end.

It's important to note that while upfront costs are a critical consideration, the total cost of ownership (TCO) should also be evaluated. TCO includes not only the initial purchase price but also installation costs, maintenance needs, and lifespan. Investing in higher-quality valves can lead to lower maintenance costs over time, presenting a more cost-effective solution in the long run.

Conclusion

When considering the purchase of a 2-inch globe valve, understanding the factors that influence price is essential for making an informed decision. While cost is a significant factor, it is crucial to balance budget constraints with the quality and requirements of the application. By evaluating materials, design features, and brand reputation, buyers can make choices that ensure reliable performance and longevity in their piping systems. The investment in a suitable globe valve ultimately contributes to the efficiency and reliability of fluid management in various industrial applications.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

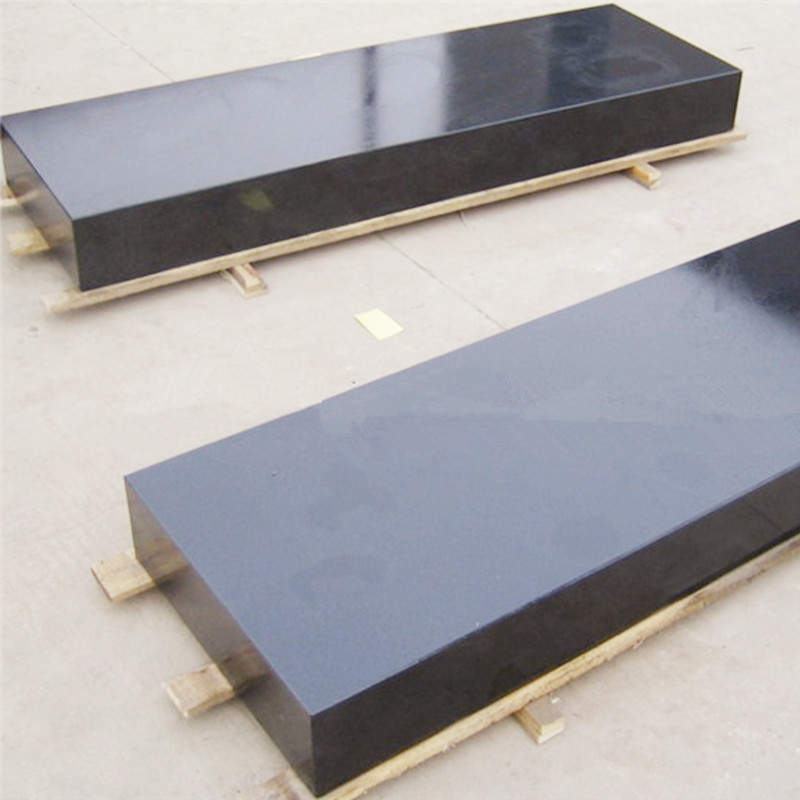

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS