May . 29, 2025 16:53 Laghachi na ndepụta

Understanding Different Valve Types and Their Industrial Applications

Valves are indispensable components in industrial systems, regulating the flow of liquids, gases, and slurries with precision. Selecting the right valve types ensures operational efficiency, safety, and longevity of infrastructure. This article explores key valve categories, procurement strategies like valve wholesale, considerations when sourcing valves for sale, and specialized designs such as types of shut off water valves and broader types of water valves.

Valve Types: Core Categories and Industrial Uses

Valves are categorized by design, function, and application. Common valve types include:

Ball Valves: Known for durability and quick shut-off, these use a rotating sphere to control flow. Ideal for oil, gas, and water systems. Their full-bore design minimizes turbulence, making them suitable for high-purity industries like pharmaceuticals.

Gate Valves: Designed for full flow or complete shut-off, they minimize pressure drop in pipelines. Commonly used in wastewater treatment plants where uninterrupted flow is critical.

Globe Valves: Excellent for throttling, these valves adjust flow rates in HVAC and steam systems. Their tapered plug design allows precise control, even in high-temperature environments.

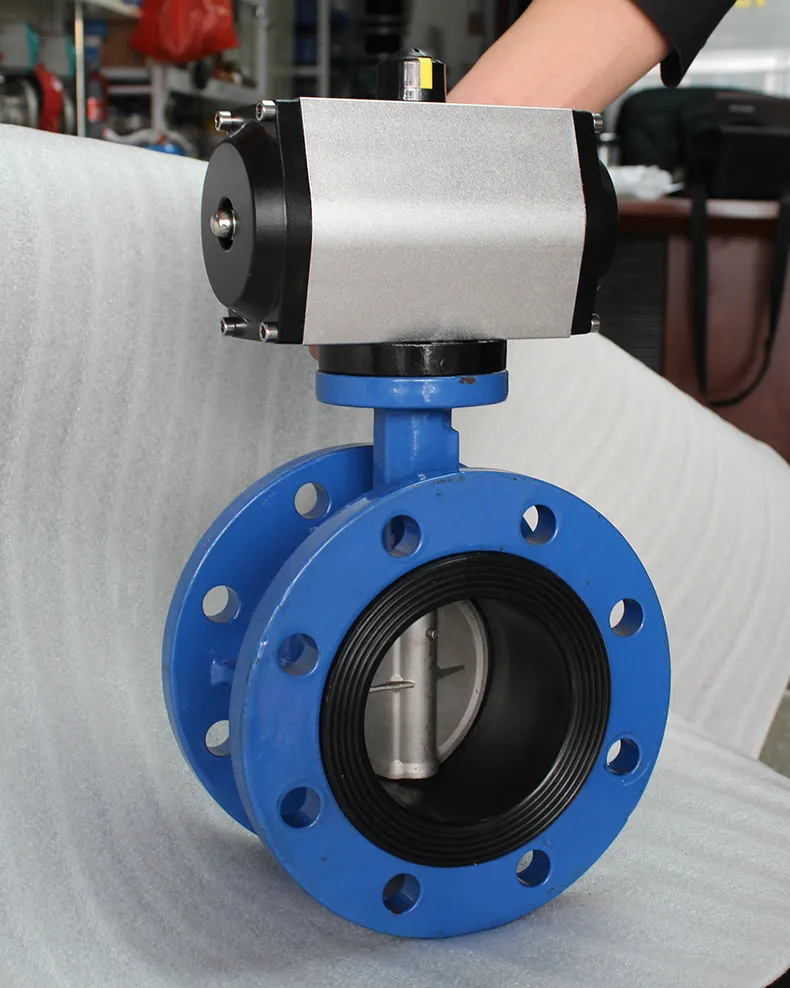

Butterfly Valves: Compact and cost-effective, they regulate flow in large-diameter pipes for water treatment or food processing. Their lightweight construction reduces installation complexity.

Material choice is critical. Stainless steel resists corrosion in chemical industries, while brass suits residential plumbing due to its malleability. Polymers like PVC are lightweight and corrosion-resistant for low-pressure applications, such as irrigation systems. Emerging materials, such as duplex stainless steel, offer enhanced strength for offshore oil rigs exposed to harsh marine conditions.

The Role of Valve Wholesale in Industrial Procurement

Purchasing through valve wholesale channels offers economies of scale, particularly for industries requiring bulk orders. Wholesale suppliers provide standardized or custom valve types, ensuring compatibility with existing systems. For example, butterfly valve wholesale options are popular in water distribution due to their balance of cost and performance.

Businesses must evaluate suppliers for certifications (e.g., API, ISO) and material traceability. Bulk purchasing reduces unit costs and ensures consistent inventory, critical for large-scale projects like power plants or municipal water networks. Additionally, wholesale partnerships often include technical support, such as valve sizing guidance or material selection advice, which optimizes system design. For industries with fluctuating demand, such as construction, wholesale agreements may include flexible delivery schedules to align with project timelines.

Evaluating Valves for Sale: Materials and Performance

When assessing valves for sale, prioritize material compatibility and operational demands. Key considerations include:

Pressure and Temperature Ratings: Ensure valves withstand system conditions without degrading. For instance, cast iron valves are cost-effective for low-pressure steam systems, while forged steel is mandatory for high-pressure oil pipelines.

Sealing Mechanisms: Rubber or PTFE seals prevent leaks in high-pressure environments. In cryogenic applications, elastomers like Viton® maintain flexibility at sub-zero temperatures.

End Connections: Flanged, threaded, or welded ends must match pipeline specifications. Flanged connections simplify maintenance in chemical plants, while welded ends provide leak-proof joints in high-vibration settings.

For types of shut off water valves, such as gate or ball valves, bronze and stainless steel are preferred for corrosion resistance. Always verify compliance with industry standards like ANSI or ISO. Non-metallic valves, such as those made from CPVC, are gaining traction in residential systems due to their resistance to chlorine-induced degradation.

Types of Shut Off Water Valves: Design and Applications

Shut-off valves are critical for isolating sections of a water system. Common types of shut off water valves include:

Gate Valves: Used in main water lines for infrequent operation. Their rising stem design provides visual confirmation of open/closed status but requires ample installation space.

Ball Valves: Provide reliable sealing in residential plumbing. Their quarter-turn operation enables rapid shut-off during emergencies.

Globe Valves: Suited for precise flow control in industrial cooling systems. Though prone to higher pressure drops, their throttling accuracy justifies their use in process control.

Materials like brass and PVC are chosen based on environmental exposure. For instance, brass valves excel in hot water systems due to thermal stability, while PVC is ideal for cold-water applications. In coastal areas, bronze valves resist saltwater corrosion, extending service life in desalination plants.

FAQS:About Valve Types Selection and Use

What factors determine the best valve types for high-pressure systems?

High-pressure systems require valve types with robust construction, such as forged steel ball valves. Sealing materials must resist deformation, and full-bore designs minimize flow restriction. Additionally, valves should undergo hydrostatic testing to validate integrity under extreme conditions.

How does valve wholesale purchasing benefit long-term infrastructure projects?

Valve wholesale reduces costs for large orders and ensures uniformity across installations. It also simplifies inventory management for projects spanning years, like pipeline networks. Centralized procurement reduces logistical delays and guarantees compatibility with future expansions.

What should buyers prioritize when sourcing valves for sale?

Focus on material grade, pressure compatibility, and supplier credibility. For valves for sale, request test reports to validate performance under simulated conditions. Avoid valves with mixed-material components unless explicitly rated for the intended application.

Why are certain types of shut-off water valves preferred in emergency scenarios?

Types of shut off water valves like ball valves enable rapid closure, critical during leaks. Their simple design reduces failure risks compared to multi-component valves. Lever-style handles or gear operators enhance usability in high-stress situations.

How do different types of water valves address corrosion resistance?

Types of water valves made from stainless steel or bronze inherently resist corrosion. Coatings like epoxy enhance durability in saline or chemically aggressive environments. For acidic fluids, Hastelloy valves offer superior performance despite higher upfront costs.

By understanding valve types, leveraging valve wholesale opportunities, and prioritizing material quality when selecting valves for sale, industries can optimize system performance. Specialized types of shut off water valves and broader types of water valves further ensure tailored solutions for diverse operational needs, from municipal utilities to heavy industrial complexes. Investing in the right valve technology not only enhances efficiency but also mitigates risks associated with system failures.

-

Why the Right Angle Ruler Reigns in MetalworkingAkụkọJul.21,2025

-

The Enduring Allure of Granite Boxes in Modern InteriorsAkụkọJul.21,2025

-

The Digital Gauging Revolution: Reshaping Thread Rings Inspection's FutureAkụkọJul.21,2025

-

How Modern Inspection Platforms Transcend Surface MeasurementAkụkọJul.21,2025

-

How Customization Drives Wholesale Success in Parallel RulersAkụkọJul.21,2025

-

Fortifying Permanent Steel Ground Anchors Against Corrosion's OnslaughtAkụkọJul.21,2025

Ngwaahịa ndị emetụtara