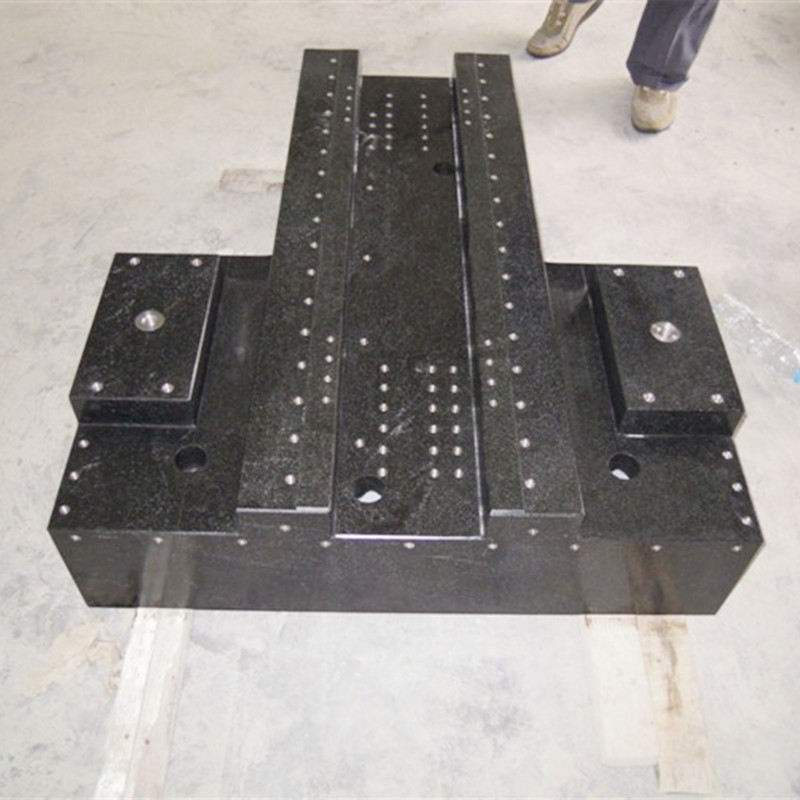

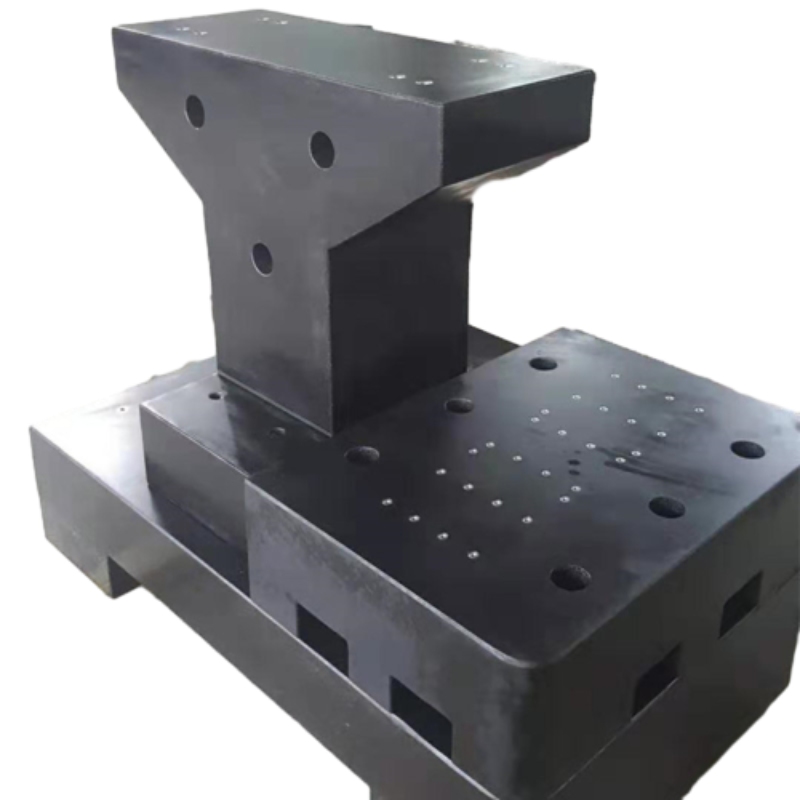

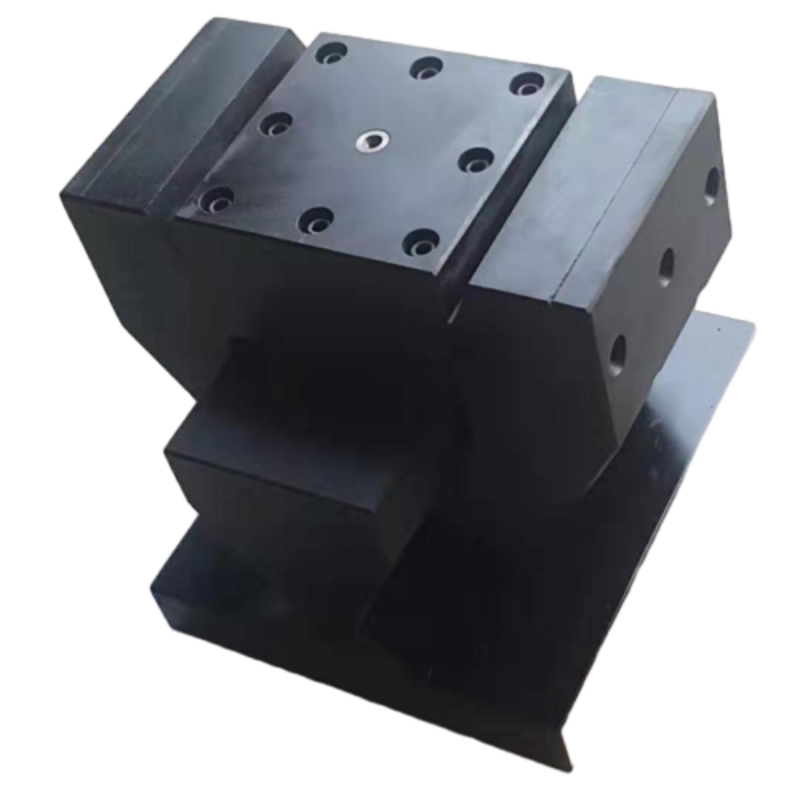

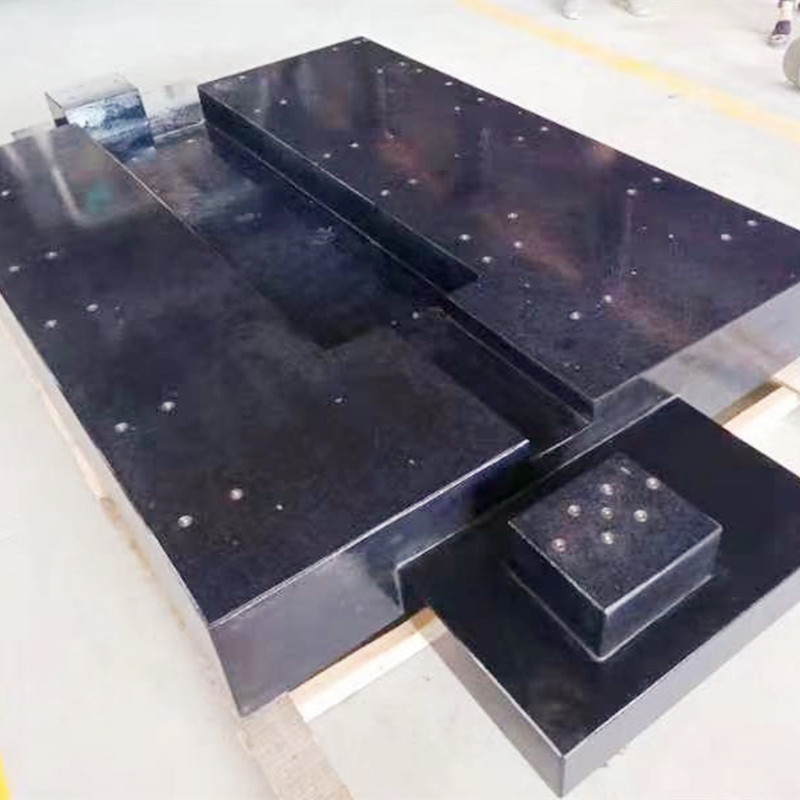

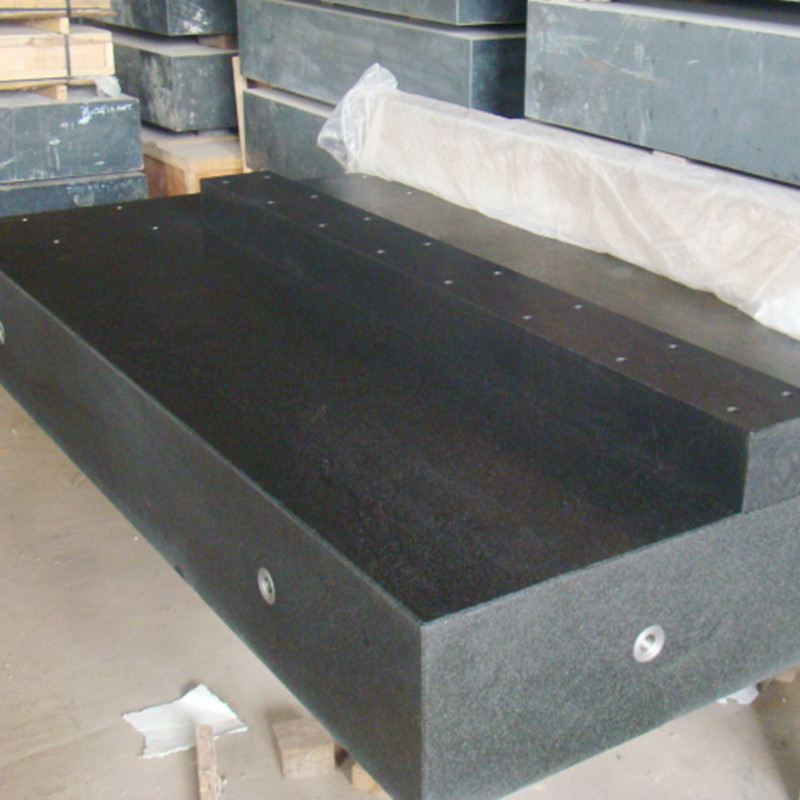

Platform atụ

Nkọwa ngwaahịa

Ebe Mmalite: Hebei

Aha ika: Storan

Nọmba Model: 1005

ihe: Granite

Agba: nwa

Ngwugwu: igbe plywood

Port: tianjin

size: ahaziri

Ọrụ: Nlele ule

Mbupu: site n'oké osimiri

Nkwakọ ngwaahịa: Plywood Box

isiokwu: Granite 00grade table ahaziri

Nkọwa nkwakọ ngwaahịa: plywood

Port: tianjin

Ịkwanye ikike: 1200 iberibe / iberibe kwa ụbọchị

ọkwa: 00

njupụta: 2500-2600kg / cubic mita

customized : yes

ike: karịa HS70

ike mkpakọ:245-254N/m

Ntinye mmiri: ihe na-erughị 0.13%

Ọnụ ego na-agbanwe: 1.3-1.5*106kg/Square centimita

Ngwa: Ntụ ụlọ ọrụ, ụlọ nyocha, mgbakọ akụkụ nkenke, mmezi ụgbọ ala

Granite Measurement Platform: Why 00 Grade Precision Is Critical for Industrial Inspection

In the realm of precision manufacturing, an inspection platform isn’t just a tool—it’s the foundation of quality control. Storan’s granite measurement platform with 00 grade precision raises the bar for industrial accuracy, addressing the critical need for reliability in applications where even micron-level deviations can impact outcomes. Here’s why 00 grade precision is non-negotiable for modern manufacturing.

The Uncompromising Standard of 00 Grade Precision

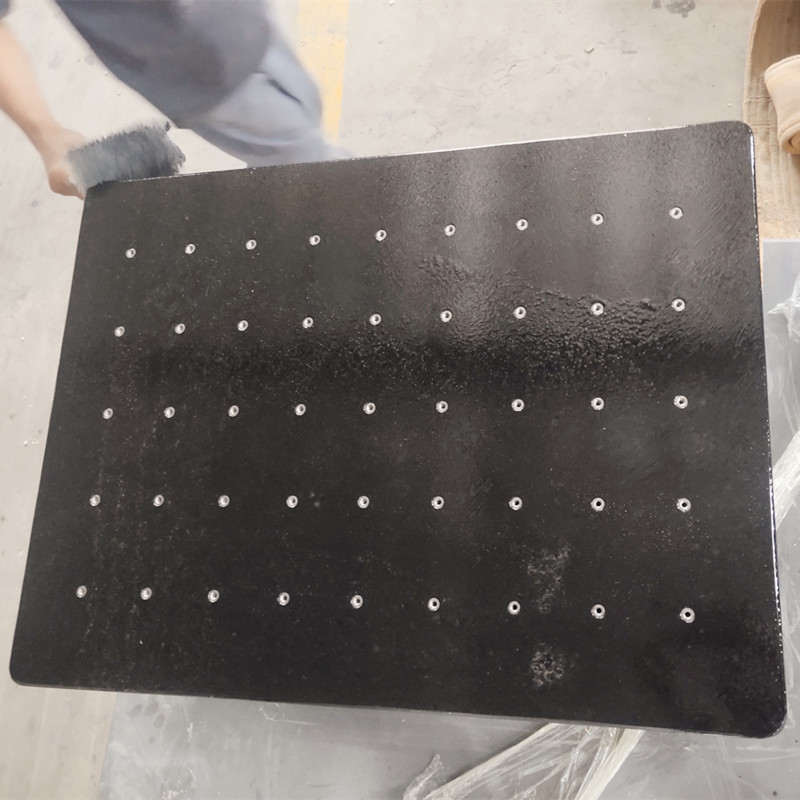

A 00 grade platform inspection ensures flatness tolerances as low as 1μm (for a 100x100mm surface), making it indispensable for industries like aerospace, semiconductors, and medical device production. Unlike lower grades, 00 precision eliminates guesswork: every component’s dimensional accuracy, flatness, and perpendicularity are validated against a surface that resists thermal expansion, vibration, and wear. For example, in aerospace engine assembly, where tight tolerances prevent catastrophic failures, our granite platforms serve as the ultimate reference, ensuring parts fit flawlessly and perform under extreme conditions.

Why Granite Is the Ideal Medium for 00 Grade Excellence

Storan’s platforms leverage the innate advantages of Jinan blue granite: a hardness rating of HS70+ that outlasts steel or marble, non-magnetic properties that eliminate interference with sensitive equipment, and a non-porous surface that repels dust and moisture. These traits make our measurement platform a stable anchor in dynamic workshop environments, where temperature fluctuations or heavy machinery vibrations could compromise lesser materials. The result? Consistent, repeatable measurements that stand up to daily use without recalibration—critical for high-volume production lines where downtime equals lost revenue.

Trust Storan for Engineered-to-Perfection 00 Grade Solutions

When your quality control depends on precision, settling for anything less than 00 grade is a risk. Storan’s granite measurement platforms are not just manufactured; they’re crafted through meticulous grinding, lapping, and rigorous testing to ensure every surface meets the strictest international standards. Whether you need a custom-sized platform for specialized machinery or a standard unit for routine platform inspection, our solutions deliver the accuracy your operations demand.

In an era where precision drives competitiveness, a 00-grade granite measurement platform isn’t an option—it’s a necessity. Elevate your inspection processes with Storan’s expertise and experience the peace of mind that comes from measuring against the industry’s gold standard.

The Science Behind Granite Inspection Platforms: HS70 Hardness & Stability Explained

In precision manufacturing, the reliability of an inspection platform hinges on the science of its material, and few materials match the engineered excellence of granite. Storan’s measurement platform leverages the unique physical properties of Jinan blue granite, particularly its HS70 hardness and thermal-mechanical stability, to set the standard for industrial platform inspection. Here’s how these characteristics make granite the ultimate choice for critical measurements.

HS70 Hardness: The Foundation of Durability

Rated at HS70 on the Shore hardness scale, our granite surpasses common alternatives like steel (HS50-60) or marble (HS40-50), creating a surface that resists scratches, dents, and wear even under heavy loads. This hardness is crucial for platform inspection tools, as it ensures the reference surface remains unaltered over decades of use, unlike softer materials that degrade over time, introducing hidden errors into measurements. For example, in a CNC machining workshop, where gauge blocks or height masters are repeatedly positioned on the platform, the HS70 surface remains flawlessly flat, maintaining accuracy without the need for frequent reconditioning.

Stability: Defying Environmental Variables

Granite’s magic extends beyond hardness to its inherent stability. With a low coefficient of thermal expansion (8.3x10⁻⁶/°C), it shrinks or expands minimally with temperature changes, critical in environments where metal platforms might warp under heat, skewing measurements. Its non-porous, crystalline structure also dampens vibrations, absorbing mechanical noise from nearby machinery to keep measurement platform readings steady. This stability is why aerospace engineers and semiconductor manufacturers trust our granite platforms: even in cleanrooms or high-temperature workshops, the surface remains a dependable reference, eliminating variables that compromise precision.

How Storan Optimizes Granite’s Natural Advantages

We don’t just source granite—we refine it. Each inspection platform undergoes precision grinding and lapping to enhance its natural properties, ensuring flatness tolerances as tight as 1μm (00 grade) while preserving the stone’s innate resistance to corrosion and magnetic interference. The result is a tool that doesn’t just meet standards but elevates them, providing manufacturers with the confidence that every measurement, from micro-component calibration to large-scale assembly checks, is anchored in scientific consistency.

Understanding the science behind granite’s performance makes one thing clear: for platform inspection where accuracy is non-negotiable, HS70 hardness and stability aren’t just features—they’re non-negotiable requirements. Storan’s granite platforms embody this science, delivering the reliability your quality control processes demand.

Ihe osise nkọwa ngwaahịa

Ejikọtara ya Ngwaahịa

Akụkọ metụtara

Thread Plug Gauge Requires Careful Handling

In the world of manufacturing and engineering, precision is non-negotiable—especially when it comes to threads, which are critical components in machinery, construction, and everyday products.

Surface plate calibration

In today's world, where precision and accuracy are crucial in various industries, the use of granite inspection tables and granite surface plates has become increasingly popular.

Ring Gauge Ensures Machining Accuracy

In the world of precision engineering, manufacturing, and quality control, accuracy is the cornerstone of reliability.