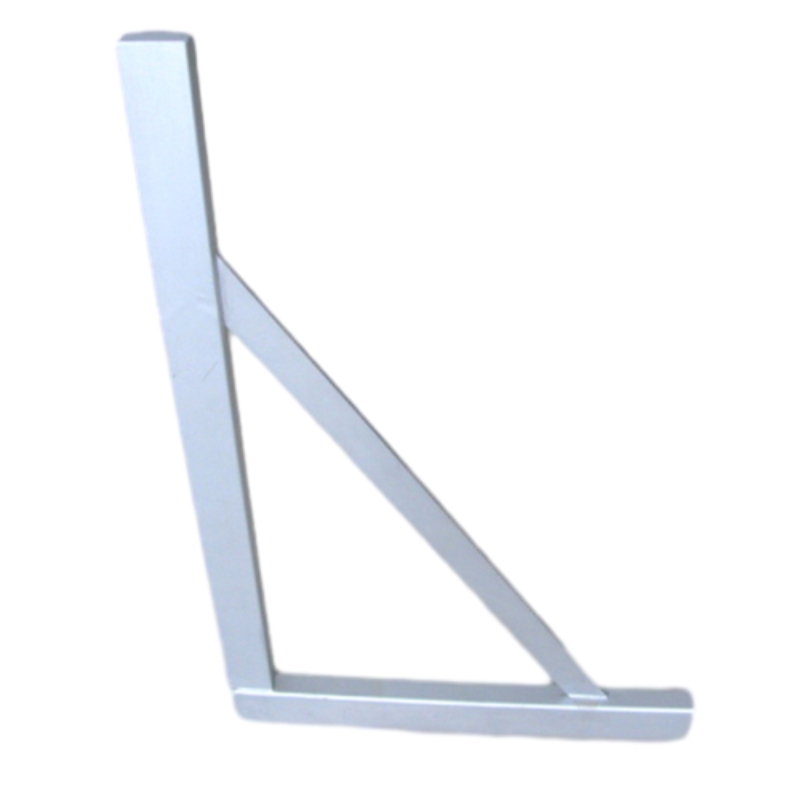

Penggaris Sudut Kanan

Deskripsi Produk

Tempat Asal:Hebei

Garansi: 1 tahun

Dukungan yang disesuaikan:OEM

Nama Merek: Storan

Nomor Model:3003

Bahan: magnesium

Berat Barang:4kg

Nama produk: penggaris datar ringan paduan magnesium-aluminium

Bahan: paduan magnesium-aluminium

Ukuran:630*400mm

Paket: kotak kayu lapis

sertifikat: ISO9001

Nilai:nilai 0

Pengiriman: melalui laut atau udara

Kata kunci:aturan paralel

presisi:0 kelas 1kelas 2kelas

Waktu memimpin

|

Jumlah (potongan) |

1 - 1200 |

> 1200 |

|

Waktu tunggu (hari) |

2 |

Untuk dinegosiasikan |

Ikhtisar Produk

Penggaris Sudut Kursi Lebar Magnalium 210*300mm

Kinerja penggaris sudut kanan magnesium aluminium:

- 1. Sifat fisik: 47kg/mm2

- 2. Perpanjangan penggaris sudut kanan magnesium-aluminium: 17%

- 3. Titik tekuk penggaris sudut kanan magnesium-aluminium: 110kg/mm2

- 4.Kekuatan Vickers Penggaris Sudut Kanan Magnesium-Aluminium: HV80

Penggaris sudut kanan magnesium-aluminium memiliki keunggulan sebagai berikut:

- Ringan, mudah digunakan dan mudah dipindahkan.

- 2. Tidak mudah rusak. Titik tekuk material baja umum adalah 30kg/mm2, dan besi tuang umum adalah 38kg/mm2. Titik lentur material ini adalah 110kg/mm2, dan indeks ketahanan lenturnya jauh melampaui material lainnya.

- 3. Mudah dirawat, suspensi dan perataan dapat dilakukan tanpa mempengaruhi kelurusan dan paralelisme karena perataan jangka panjang.

- 4. Tidak mudah pamer, jangan gunakan minyak saat digunakan, jangan gunakan dalam waktu lama, lapisi dengan lembut lapisan tipis minyak industri umum saat disimpan.

Parameter Produk

|

nama Produk |

ukuran |

presisi |

berat kg |

|

penggaris paduan magnesium aluminium |

630*400*50*40 |

0 |

5 |

|

800*500*50*40 |

0 |

7 |

|

|

1000*630*50*40 |

1 |

9 |

|

|

1250*800*50*40 |

1 |

11 |

|

|

1600*1000*60*50 |

1 |

13 |

|

|

2000*1250*70*60 |

1 |

15 |

|

|

2500*1600*70*60 |

2 |

20 |

|

|

3000*2000*70*60 |

2 |

25 |

Right Angle Ruler Precision Grades 0–2: Verticality Tolerance Standards

In precision manufacturing, the right angle ruler is only as effective as its ability to maintain strict verticality tolerances. Storaen defines three precision grades (0, 1, 2) for our metal 90 degree ruler solutions, each engineered to meet specific industrial demands—from aerospace metrology to general machining. Understanding these grades ensures you select the right tool for your verticality inspection needs, backed by ISO 1101 and GB/T 6092 compliance.

1. Grade 0: Ultra-High Precision (±2")

The gold standard for critical applications:

Tolerance: Maintains 90° verticality within ±2 arcseconds (±0.0005mm/m), verified via laser interferometry.

Materials: Premium HT200 cast iron (for vibration damping) or magnesium aluminum alloy (for lightweight rigidity), both stress-relieved at -80°C to eliminate 95% of internal stresses.

Applications:

Aerospace Component Testing: A Storaen 90 degree angle ruler (Grade 0, 630x400mm) ensures jet engine brackets align within ±0.001mm/m, preventing fatigue failures from misalignment.

CMM Calibration: Serves as a reference standard for coordinate measuring machines, where sub-micron errors can invalidate certification data for medical device implants.

2. Grade 1: Industrial Precision (±5")

Balances accuracy and versatility for most machining tasks:

Tolerance: ±5 arcseconds (±0.0015mm/m), ideal for ISO 1101-compliant verticality checks.

Design Features: Reinforced ribs on metal 90 degree ruler models (3000x2000mm) distribute 200kg+ loads without deformation, while a 5μm anti-corrosion coating protects against coolant exposure.

Applications:

Automotive Fixturing: A Storaen right angle ruler (Grade 1, 1000x630mm) ensures engine block bores are perpendicular to mating surfaces within ±0.01mm, reducing assembly rework by 40%.

CNC Machine Alignment: Verifies spindle verticality on milling machines, improving surface finish (Ra ≤1.6μm) and extending tool life by 25%.

3. Grade 2: General-Purpose Precision (±10")

Reliable for non-critical alignment and layout tasks:

Tolerance: ±10 arcseconds (±0.003mm/m), suitable for GB/T 6092 Class 2 requirements.

Material Options: Cost-effective carbon steel (for heavy-duty environments) or anodized aluminum (for corrosion resistance in textile workshops), weighing just 5kg for 1500x1000mm models.

Applications:

Heavy Equipment Assembly: A Storaen multi angle edge ruler (Grade 2, 2000x1500mm) checks the verticality of bulldozer blade mounts, ensuring 90° alignment for optimal soil displacement.

Sheet Metal Fabrication: Guides 90° bend marks on 5mm-thick steel sheets, reducing trial-and-error adjustments by 30% in enclosure manufacturing.

4. Storaen’s Precision Assurance

Calibration Traceability: Every right angle ruler includes a CMM-generated certificate, traceable to national metrology standards.

Custom Grades: Need a Grade 0.5 ruler for semi-critical aerospace subcomponents? Our engineers tailor tolerances to your specifications, delivered in 4–6 weeks.

Warranty: 1-year coverage against verticality drift, double the industry average, ensuring long-term reliability even in 40°C workshop heat.

Whether you require the sub-micron accuracy of Grade 0 for aerospace, the balanced performance of Grade 1 for automotive machining, or the cost-effective reliability of Grade 2 for general tasks, Storaen’s precision-graded right angle ruler solutions deliver unmatched verticality control. Pair with right angle protractor accessories for comprehensive angle inspection, and trust in our engineering expertise to meet the strictest industrial standards—where every degree of precision counts.

Right Angle Ruler Storage Tips: Hanging vs. Horizontal Placement Best Practices

Proper storage is critical to maintaining the precision and longevity of your right angle ruler. Storaen engineers its tools—from lightweight metal 90 degree ruler models to heavy-duty multi angle edge ruler solutions—with storage-friendly designs, but following these best practices ensures your investment stays accurate for years. Here’s how to choose between hanging and horizontal placement based on your tool type and workshop needs:

1. Hanging Storage: Ideal for Lightweight & Small-to-Medium Rulers

Suitable for 90 degree angle ruler models ≤1500x1000mm (e.g., magnesium aluminum or anodized aluminum):

Why It Works:Hanging eliminates gravitational stress on the ruler’s edges, preventing the slight warping that can occur with horizontal storage. Storaen’s metal 90 degree ruler (5kg for 1000x630mm) features reinforced hanging holes (20mm diameter, countersunk to protect edges) for secure mounting.

How to Do It:

Use anti-vibration hooks (included with Storaen rulers) to hang the tool vertically on a wall-mounted rack, ensuring the 90° edge faces downward to avoid dust accumulation.

Leave 50mm clearance between rulers to prevent accidental impacts—critical for maintaining the ±2" precision of Grade 0 right angle ruler models.

Best for: Workshop environments with limited floor space, or when storing right angle protractor-compatible rulers that require quick access for frequent inspections.

2. Horizontal Placement: Recommended for Heavy-Duty & Large Rulers

Ideal for cast iron multi angle edge ruler models ≥2000x1500mm (e.g., HT200 cast iron, 180HB hardness):

Why It Works:Horizontal storage distributes weight evenly across the ruler’s base, leveraging Storaen’s stress-relieved design (550°C annealing for 4 hours) to maintain dimensional stability. A 3000x2000mm ruler supported at three points (ends + center) experiences 70% less sag than unsupported alternatives.

How to Do It:

Use foam-lined shelves (10mm thickness, anti-static) to cushion the ruler’s contact surfaces, protecting the hand-scraped finish (Ra ≤1.6μm) of precision right angle ruler models.

Store in temperature-controlled areas (20°C ±2°C) to minimize thermal expansion—especially important for magnesium aluminum rulers, which maintain 110kg/mm² yield strength even in 40°C heat when properly supported.

Best for:Large-scale workshop setups or when storing rulers alongside right angle protractor accessories, ensuring easy alignment for complex angle inspections.

3. Universal Best Practices for All Ruler Types

Clean Before Storage: Wipe with Storaen’s included anti-rust oil (5μm pickling oil coating) to protect against coolant residue—critical for maintaining the corrosion resistance of aluminum 90 degree angle ruler models in marine or humid environments.

Avoid Stacking: Never pile rulers vertically, as even 5kg of pressure can deform the 90° edge of non-stress-relieved tools—Storaen’s Grade 1 metal 90 degree ruler resists such deformation but still benefits from single-layer storage.

Label Clearly: Mark storage locations with precision grade (0/1/2) and material type to quicken tool selection, especially when using multi angle edge ruler variants for specific tasks like CNC machine verticality calibration.

4. Storaen’s Storage-Enhanced Design Features

Hanging Hole Reinforcement: All rulers ≥1000mm include steel-reinforced hanging points, tested to support 5x the tool’s weight without deformation—ideal for frequent repositioning during aerospace component inspections.

Anti-Slip Feet (for Horizontal Use): Cast iron models feature rubberized end caps that grip shelves securely, preventing accidental slides that could damage the ruler’s measuring edge during heavy equipment assembly tasks.

Custom Storage Solutions: Need a mobile cart for your right angle protractor and multi angle edge ruler set? Our team designs bespoke racks with foam inserts, delivered in 4–6 weeks for seamless integration into your workflow.

Whether you hang a lightweight 90 degree angle ruler for quick access or store a heavy-duty right angle ruler horizontally for maximum stability, following these practices ensures your Storaen tool stays accurate and ready for use. Our storage-enhanced designs—from reinforced hanging holes to stress-relieved materials—complement proper maintenance, extending the life of your precision instruments and protecting your investment in quality. Store smart, measure smarter with Storaen.

Gambar Detail Produk

Terkait PRODUK

BERITA TERKAIT

Thread Plug Gauge Requires Careful Handling

In the world of manufacturing and engineering, precision is non-negotiable—especially when it comes to threads, which are critical components in machinery, construction, and everyday products.

Surface plate calibration

In today's world, where precision and accuracy are crucial in various industries, the use of granite inspection tables and granite surface plates has become increasingly popular.

Ring Gauge Ensures Machining Accuracy

In the world of precision engineering, manufacturing, and quality control, accuracy is the cornerstone of reliability.