Nov . 30, 2024 21:42 Back to list

Essential Measuring Tools for Precision in Metal Fabrication Projects

Measuring Tools in Metal Fabrication

In the world of metal fabrication, precision is paramount. Errors can lead to costly waste or structural failures. Therefore, having the right measuring tools is essential for achieving accuracy and efficiency throughout the fabrication process. This article explores various measuring tools used in metal fabrication, their purposes, and best practices for utilizing them effectively.

1. Calipers

Calipers are one of the most versatile measuring tools in metal fabrication. They come in various forms, such as digital, dial, and vernier calipers. Calipers measure internal and external dimensions, as well as depths, with a high degree of accuracy. When using calipers, it’s vital to ensure that the measuring surfaces are clean and free of debris to avoid any inaccuracies. Digital calipers are particularly useful since they offer easy-to-read displays and can automatically convert measurements between metric and imperial units.

2. Micrometers

For even more precise measurements, micrometers are often employed. These tools are ideal for measuring small dimensions accurately, such as the thickness of a sheet of metal or the diameter of a rod. Like calipers, micrometers can have different types such as external, internal, and depth micrometers. Proper technique is crucial when using a micrometer; the object being measured should be gently clamped without excessive force to ensure accuracy.

3. Tape Measures

Tape measures are a staple in any fabrication shop. They provide a quick way to obtain linear dimensions and are essential for larger measurements where other tools might not be practical. A good quality tape measure with clear markings will facilitate accurate readings. Additionally, it's advisable to always pull the tape taut and at eye level to avoid parallax errors.

Squares, such as framing squares and machinist squares, are crucial for ensuring right angles in constructions. They help maintain the integrity of structures, ensuring that joints fit together properly. Levels, including torpedo and spirit levels, are vital for determining horizontal and vertical alignments. Ensuring that a structure is level can prevent unwanted stress and potential failures in the fabrication process.

5. Gauges

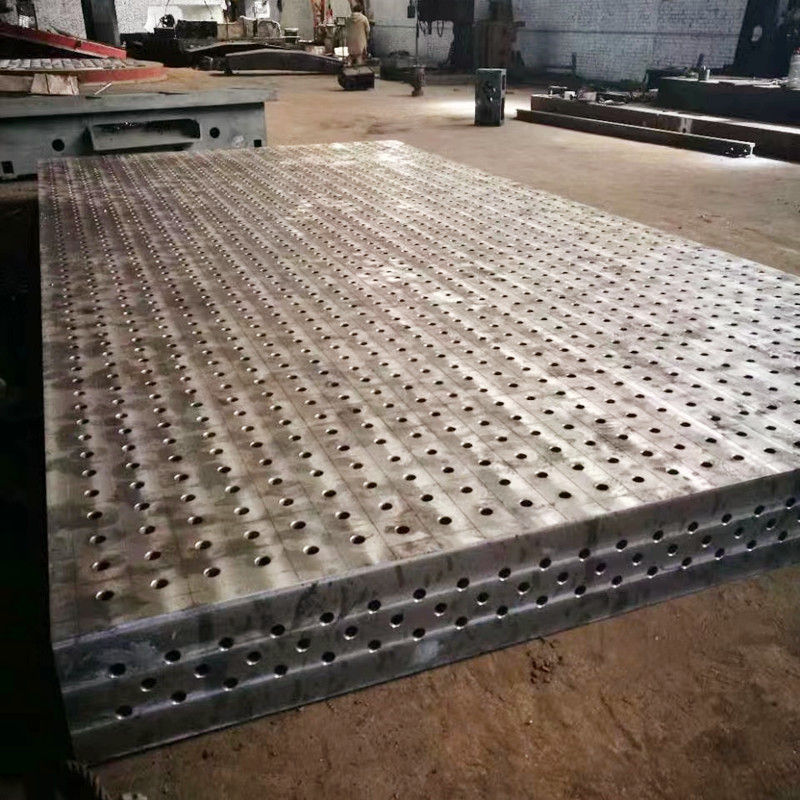

metal fabrication measuring tools

Various types of gauges are used in metal fabrication to measure different attributes. For example, thickness gauges ascertain the thickness of materials, while feeler gauges measure gap widths between two parts. Additionally, depth gauges can measure how deep a feature goes into a material. Employing the appropriate gauge for specific measurements ensures that components fit together accurately, reducing rework and wastage.

6. Protractors

In applications where angles are critical, protractors come in handy. They allow fabricators to measure or set angles with precision. Digital protractors provide additional benefits through easy-read displays and often the ability to store measurements. When using a protractor, ensure that it's aligned correctly with the materials being measured for the best accuracy.

7. Laser Measuring Tools

In modern metal fabrication, laser measuring tools have gained popularity due to their speed and accuracy. These tools offer non-contact measurement options with the precision that traditional tools might struggle to provide, particularly over long distances. Laser measures are especially useful for large fabrication projects in warehouses or construction sites.

Best Practices for Measurement

To ensure accuracy in metal fabrication, several best practices should be followed

1. Calibration Regularly calibrate measuring tools to ensure consistent accuracy. 2. Condition Keep tools clean and free of debris to avoid measurement errors. 3. Environment Be mindful of the environment, as temperature and humidity can affect measurements. 4. Technique Use consistent techniques when taking measurements to improve repeatability and reliability. 5. Record Keeping Document measurements effectively, especially in projects that require multiple components to match precisely.

Conclusion

Measuring tools are indispensable in the world of metal fabrication. Each tool serves a unique purpose, helping fabricators achieve the precision necessary for high-quality work. By understanding how to use these tools effectively and following best practices, manufacturers can minimize errors, maximize efficiency, and maintain high standards in their fabrication processes. Investing in quality measuring tools is an investment in the integrity and success of any metal fabrication project.

-

Thread Plug Gauge Our Promise of Measurement ExcellenceNewsAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyNewsAug.22,2025

-

Check Valve Types for High Rise BuildingsNewsAug.22,2025

-

Water Control Valve for Irrigation SystemsNewsAug.22,2025

-

Gate Valve with Soft Seal TechnologyNewsAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsNewsAug.22,2025

Related PRODUCTS