Okt . 22, 2024 13:23 Back to list

control valve price

Understanding Control Valve Prices Factors and Variations

Control valves play a crucial role in various industrial applications, managing the flow of fluids and gases to ensure optimal process efficiency

. However, one of the most pressing questions for procurement and engineering teams is What factors influence control valve prices? Understanding the components that determine pricing can assist businesses in making informed purchasing decisions.1. Type of Control Valve Prices can vary significantly depending on the type of control valve. Common types include globe valves, ball valves, butterfly valves, and gate valves. Each design has its advantages and disadvantages, and the complexity of the design often correlates with the price. For instance, ball valves are generally more expensive due to their robust design and efficiency in fluid control compared to simpler gate valves.

2. Materials Used The materials used in the construction of control valves directly impact pricing. Valves can be made from various metals including stainless steel, brass, and carbon steel, as well as plastic compounds for certain applications. Stainless steel valves, known for their corrosion resistance and durability, are usually priced higher than their carbon steel counterparts. Additionally, if specialized materials are required for high-temperature or high-pressure applications, costs will increase.

control valve price

3. Size and Specifications The size of the control valve plays a significant role in its price. Larger valves typically require more material and complex manufacturing processes, leading to higher costs. Moreover, specific specifications such as pressure ratings, flow coefficients (Cv), and actuator types can add to the complexity and, consequently, the price of the valve.

4. Automation Features Modern control valves often come with automation features such as electric or pneumatic actuators. These automated systems enhance precision and efficiency but also increase the overall cost. Organizations must consider whether the benefits of automation align with their budget and operational needs.

5. Manufacturer Reputation and Warranty Price variations can also be attributed to the reputation of the valve manufacturer. Well-established brands with proven reliability might command higher prices but often provide longer warranties and better customer support. Investing in high-quality products from reputable manufacturers can translate to lower maintenance costs in the long run.

Conclusion Understanding the factors that influence control valve prices is essential for organizations looking to optimize their purchasing process. By considering the type of valve, materials, size, automation features, and manufacturer reputation, businesses can make informed decisions that align with their operational needs and budget constraints. A thoughtful approach to procurement can lead to enhanced efficiency, reliability, and ultimately, a better return on investment.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

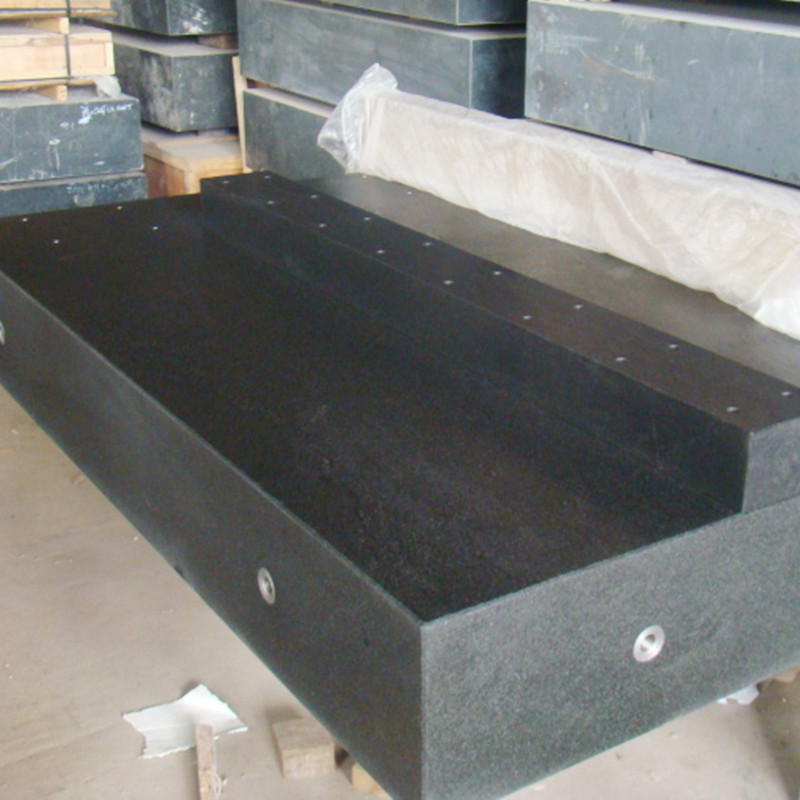

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS