Nov . 16, 2024 10:54 Back to list

2 inch gate valve with 2% flow capacity for efficient fluid control applications

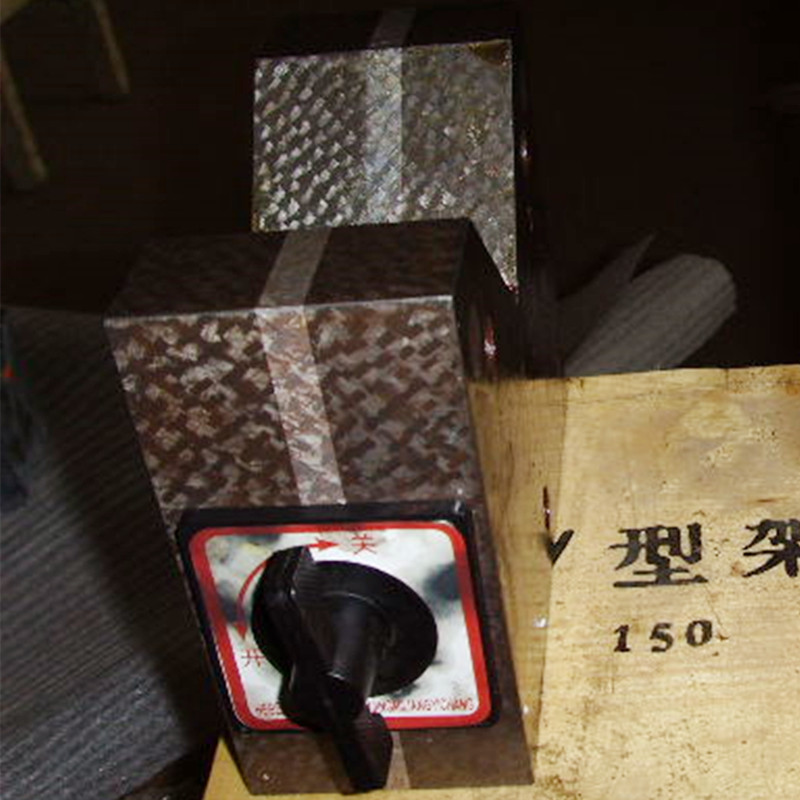

Understanding the 2% 201% 202 Inch Gate Valve

Gate valves are a crucial component in many fluid control systems, primarily because they allow for the quick and safe shut-off of the flow of liquids or gases. Among the various types of gate valves, the 2% 201% 202 inch gate valve has gained recognition for its design, efficiency, and versatility in multiple applications. This article will explore its features, uses, and importance in industrial settings.

Features of the 2% 201% 202 Inch Gate Valve

The designation 2% 201% 202 inch refers to specific dimensions and design specifications that are vital in maintaining the effectiveness of the valve. Typically, these valves have a nominal diameter of either 2 inches or 2.5 inches, making them suitable for various piping systems. The construction of these gate valves usually involves durable materials, such as stainless steel, cast iron, or brass, which ensure longevity and resistance to corrosion.

One of the primary features of a gate valve is its ability to provide a straight-through flow path. This results in minimal pressure drop and reduced turbulence within the fluid transport system. The design incorporates a wedge-shaped disc that moves perpendicular to the flow, facilitating complete open or closed positions. This attribute makes the gate valve ideal for applications where a full shut-off is necessary, such as in water supply systems, petroleum pipelines, and chemical processing facilities.

Applications of the 2% 201% 202 Inch Gate Valve

2 1 2 inch gate valve

The versatility of the 2% 201% 202 inch gate valve is evident in its range of applications. In municipal water systems, these valves are often utilized to control water flow and pressure, ensuring that the supply remains stable and reliable for consumers. In industrial settings, they are employed to handle various fluids, from non-corrosive liquids to aggressive chemicals, depending on the material composition of the valve.

In the oil and gas sector, gate valves are used in pipelines to facilitate the safe transportation of hydrocarbons. Their robust construction ensures they can withstand high pressures and temperatures, making them essential for maintaining operational integrity. Additionally, gate valves are also used in HVAC systems, where they help manage the flow of water and other fluids necessary for heating and cooling processes.

Importance of Maintenance and Operation

While gate valves are designed for durability and efficiency, proper maintenance is critical for ensuring their longevity and optimal performance. Regular inspections can prevent issues like leaks or blockages, which can lead to costly downtime or even damage to other system components. Operators must also be trained to handle these valves correctly, as improper operation can result in mechanical failures.

In conclusion, the 2% 201% 202 inch gate valve is an essential component in a wide range of fluid systems. Understanding its features, applications, and maintenance requirements can help ensure that it performs efficiently and reliably. As industries continue to evolve and require more sophisticated fluid control mechanisms, the role of these gate valves becomes increasingly vital, influencing both operational success and safety standards across the board.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS