Նյմ . 15, 2024 10:27 Back to list

y strainer flange type

Understanding Y Strainer Flange Type A Comprehensive Overview

Y strainers play a crucial role in various industrial applications by filtering out unwanted debris and particulates from fluid systems. The Y shape of these strainers not only provides structural integrity but also allows for efficient fluid flow. Among the various types available, the flange type Y strainer stands out for its versatility and ease of installation.

Design and Features

The flange type Y strainer features a body shaped like the letter Y, which facilitates the separation of impurities from the flow. This design is instrumental in minimizing pressure drops across the strainer, ensuring that the system operates smoothly. The flanged ends allow for easy connection to pipelines, making installation straightforward in areas where maintenance and replacement might be required.

Typically constructed from materials like stainless steel, cast iron, or carbon steel, flange type Y strainers are built to withstand various operating conditions. These materials confer resistance against corrosion, high temperatures, and pressure, making them suitable for a wide range of industries, including oil and gas, water treatment, and chemical processing.

Working Principle

The operation of a Y strainer is relatively simple. The fluid enters through the inlet and flows into the strainer body, where it encounters a mesh or perforated filter element. As the fluid passes through this filter, solid particles are captured, preventing them from entering downstream equipment. The cleaned fluid then exits through the outlet, ensuring that the system remains efficient and free of blockages.

y strainer flange type

Applications

Flange type Y strainers are immensely popular across various sectors. In the water treatment industry, they protect pumps and valves from clogging, ensuring smooth operations. In the chemical processing industry, they are used to filter out unwanted particles from catalysts and other substances. The oil and gas sector also relies on Y strainers to ensure the integrity of pipelines and protect sensitive equipment from damage caused by particulates.

Maintenance

Proper maintenance of flange type Y strainers is essential to ensure optimal performance. Regular inspection and cleaning of the filter element can prevent pressure drops and flow restrictions. Many designs incorporate a blow-off valve that allows for easy removal of accumulated debris without the need for complete disassembly. This feature is particularly beneficial in minimizing downtime, as maintenance can be performed quickly and efficiently.

Conclusion

The flange type Y strainer is an indispensable component in various fluid systems across multiple industries. Its robust design, ease of installation, and straightforward maintenance requirements make it a favorable choice for engineers and system designers. By implementing this essential device, industries can enhance the reliability and efficiency of their operations, ensuring that they are well-equipped to handle the challenges of modern fluid management. In an age where operational efficiency is paramount, the Y strainer flange type represents a blend of practicality and performance, helping companies to achieve their goals while maintaining system integrity.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

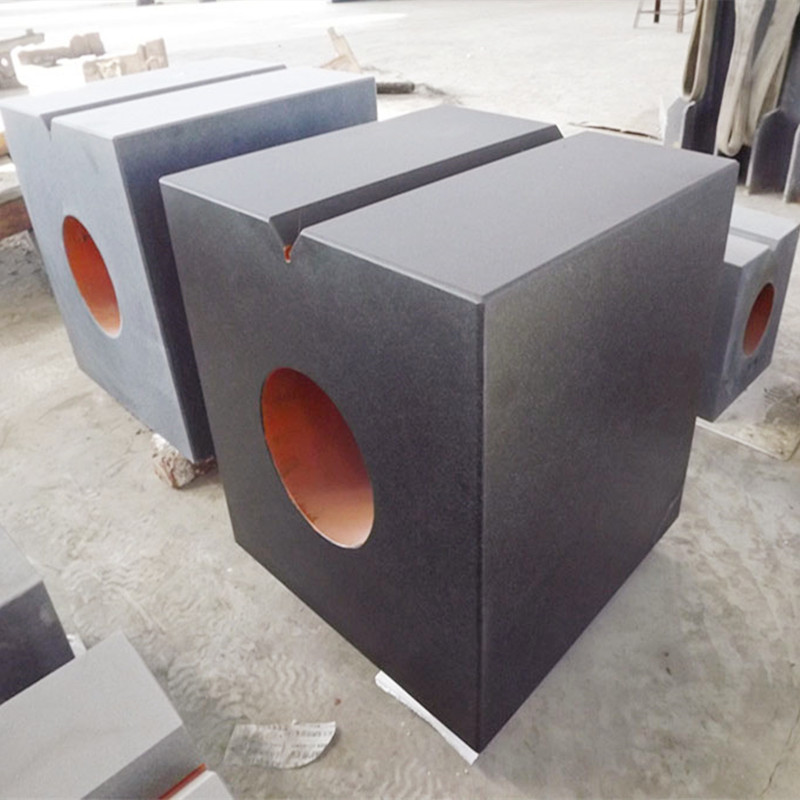

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS