Դկտ . 05, 2024 08:21 Back to list

Various Types of Micrometers and Their Applications in Precision Measurement

Types of Micrometers A Comprehensive Guide

Micrometers are precision measuring instruments commonly employed in mechanical and engineering applications to measure small distances or thicknesses with remarkable accuracy. They are indispensable tools in workshops, laboratories, and manufacturing settings, where even the slightest miscalculation can lead to significant quality control issues. Understanding the different types of micrometers is essential for selecting the right tool for specific measurement needs.

1. Outside Micrometer

The outside micrometer, also known as a micrometer caliper, is the most commonly used type of micrometer. It is designed to measure the external dimensions of an object, such as the thickness of a metal sheet or the diameter of a rod. The device consists of a C-shaped frame that holds a calibrated screw. The measurement is taken by turning the thimble, which moves the spindle to contact the object being measured. Outside micrometers typically have measuring ranges from 0 to 25 mm, 25 to 50 mm, and so on, and they can achieve accuracy to within 0.01 mm (10 microns).

2. Inside Micrometer

In contrast to the outside micrometer, the inside micrometer is used to measure the internal dimensions of objects, such as the diameter of holes or the width of grooves. This type of micrometer features interchangeable rods that allow for various measurement ranges. Inside micrometers are crucial for ensuring that parts fit together properly in assembly processes. With precision and consistency, they can measure dimensions with an accuracy of up to 0.01 mm.

3

. Depth MicrometerDepth micrometers enable users to measure the depth of holes, grooves, or recesses accurately. This tool consists of a micrometer head mounted on a vertical rod, allowing for the measurement of depth from the surface to the bottom of the cavity. Depth micrometers are invaluable in machining and engineering applications where precise depth measurements are critical. They typically have a range that can vary from 0 to 100 mm or more, depending on the model.

type of micrometre

4. Digital Micrometer

Technology has revolutionized the world of measurement, and digital micrometers are at the forefront of this transformation. Digital micrometers provide a digital readout of measurements, making it easy to obtain accurate results without the potential for human error inherent in analog devices. Some models even feature data output capabilities for ease of integration with computers and programming systems. Digital micrometers can be available in all types—outside, inside, or depth—and offer high accuracy and ease of use.

5. Blade Micrometer

A specialized variant of the outside micrometer, the blade micrometer is designed for measuring thin materials, such as wires or films. It utilizes a very narrow measuring surface that can easily fit between layers without causing damage or deformation to the material. The design allows for precise measurement of extremely small thicknesses, making it an essential tool in industries like electronics and textiles.

6. Vernier Micrometer

The vernier micrometer, also known as the vernier caliper, is a tool that combines the functions of a traditional caliper and a micrometer. It provides measurements with greater precision by using a movable secondary scale (the vernier scale) to enhance the basic measurement made by a main scale. This type of micrometer is versatile, allowing users to measure both external and internal dimensions, along with depths, all within a single tool.

Conclusion

Micrometers, in all their forms, play a pivotal role in achieving precision in numerous applications. From the commonly used outside micrometer to the advanced digital versions, each type serves a unique purpose, ensuring that engineers and manufacturers can create quality products that meet exact specifications. Understanding the different types of micrometers and their applications not only enhances measurement accuracy but also aids in the overall efficiency of manufacturing processes. Consequently, selecting the right micrometer type for specific applications is of utmost importance for professionals in mechanical engineering, manufacturing, and quality control.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

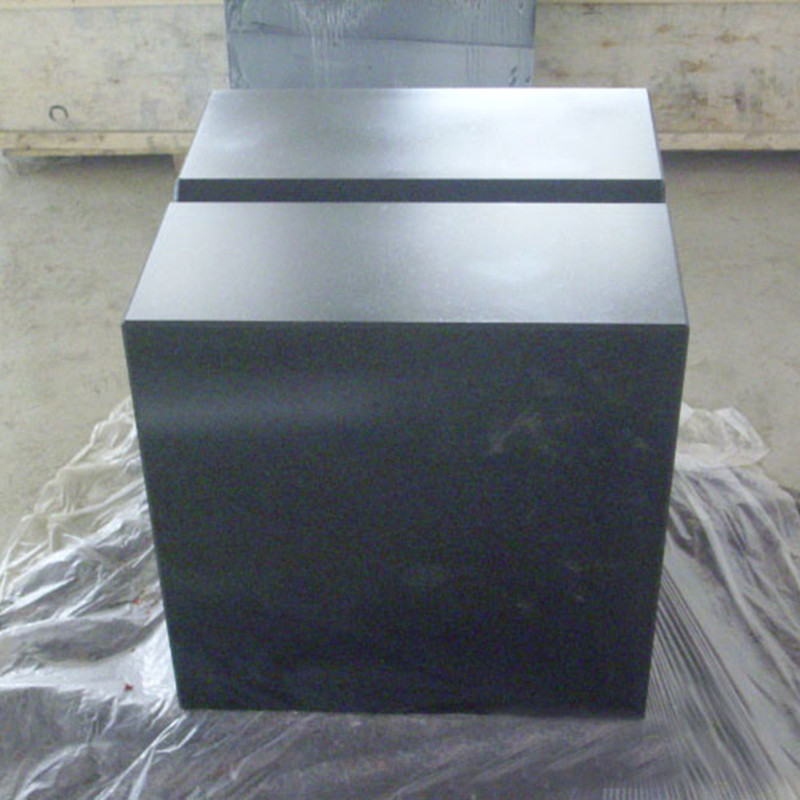

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS