Նյմ . 30, 2024 16:13 Back to list

Internal Taper Measurement Tools for Precision Engineering Applications and Quality Control

The Importance of Internal Taper Gauges in Precision Engineering

In the realm of precision engineering and manufacturing, the accuracy of measurements is paramount. One of the critical tools used to ensure precision in assessing the dimensions of conically shaped internal features is the internal taper gauge. This specialized instrument plays a vital role in quality control processes, allowing engineers and technicians to achieve the high standards required in modern production.

What is an Internal Taper Gauge?

An internal taper gauge is a measuring tool designed to determine the angle and diameter of internal tapering surfaces within a component. These surfaces are often found in parts such as engine cylinders, valve seats, and various fittings. The primary function of the gauge is to provide accurate readings, which are essential for ensuring proper fit, function, and safety of the mechanical assembly.

Internal taper gauges come in various forms, including electronic versions that offer digital readings and traditional mechanical types that utilize analog measurements. Regardless of the type, the principal focus remains on achieving precision in the assessments being made.

Types of Internal Taper Gauges

There are several types of internal taper gauges available, each suited for different applications

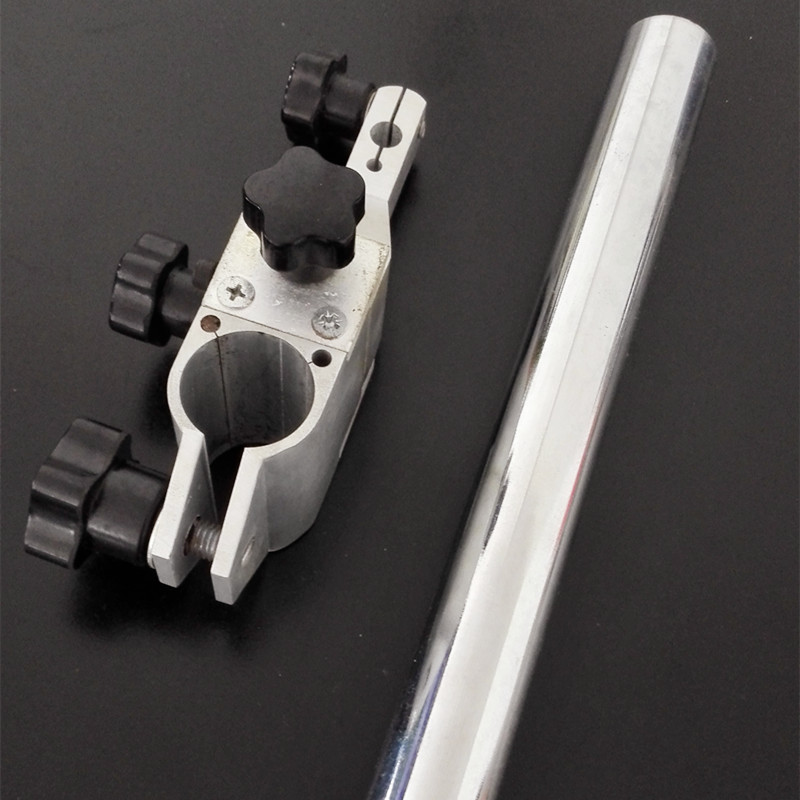

1. Mechanical Taper Gauges These manually operated tools consist of a tapered rod calibrated to specific measurements. Users insert the gauge into the internal taper, and by noting where it fits snugly, they can determine the taper's angle and dimensions.

2. Digital Taper Gauges The advancements in technology have led to the development of digital internal taper gauges, which provide electronic readings. They often feature high-resolution displays and can store measurements for future reference, enhancing efficiency and accuracy.

3. Self-Aligning Taper Gauges These are designed to automatically align with the internal surfaces being measured. This feature minimizes user error and provides a more reliable reading, especially in complex geometries.

internal taper gauge

Applications in Industry

Internal taper gauges are widely used in various industries, including automotive, aerospace, and manufacturing. For example, in the automotive industry, proper measurement of taper angles in engine components is essential for ensuring that parts fit together correctly and function efficiently. Furthermore, in aerospace applications, where precision is critical, any deviation in measurements can lead to significant safety and performance issues.

The gauge is also instrumental during the quality assurance processes in manufacturing facilities. Operators routinely measure products to ensure they meet the specified tolerances before they move to the next stages of production or assembly.

Advantages of Using Internal Taper Gauges

The use of internal taper gauges offers several advantages. First and foremost is the increased accuracy they provide. Engineers can detect even the slightest deviations in measurements, ensuring that components will function as intended within their specific applications.

Additionally, they contribute to cost savings by reducing waste and preventing defective products from moving further along the production line. By identifying issues early in the manufacturing process, companies can avoid costly rework and maintain their reputation for quality.

Moreover, internal taper gauges help streamline the inspection process. They can be used efficiently and quickly, allowing quality control technicians to assess multiple components in a shorter time frame. This efficiency is crucial in high-paced production environments.

Conclusion

In summary, internal taper gauges are an indispensable tool in precision engineering, playing a pivotal role in ensuring the accuracy and quality of internal tapered surfaces in various components. As technology continues to advance, the capabilities of these gauges are expected to grow, further enhancing their importance in manufacturing and engineering. Investing in high-quality internal taper gauges and training personnel in their effective use is essential for any organization focused on maintaining high standards of quality and efficiency in their production processes. The precision they provide is not just a benefit; it's a necessity in today's competitive industrial landscape.

-

The Role of Cast Iron T Slot Plates in RoboticsNewsMay.12,2025

-

The Importance of Parallel Rulers in Mechanical EngineeringNewsMay.12,2025

-

Heavy-Duty Applications for Granite Surface Plate for SaleNewsMay.12,2025

-

Cast Iron Y Strainer: A Reliable Solution for Dirty FluidsNewsMay.12,2025

-

Boosting Workshop Productivity Using Granite BlocksNewsMay.12,2025

-

Water Control Valves: Essential Components for Fluid RegulationNewsMay.08,2025

Related PRODUCTS