Սպտ . 04, 2024 22:46 Back to list

160mm gate valve

Understanding the 160mm Gate Valve A Comprehensive Overview

The gate valve, especially one with a diameter of 160mm, plays a crucial role in various industrial applications. It is predominantly used for regulating the flow of liquids and gases in pipelines, and its distinctive design allows for both manual and automated control. This article delves into the specific features, advantages, and applications of the 160mm gate valve.

Design and Functionality

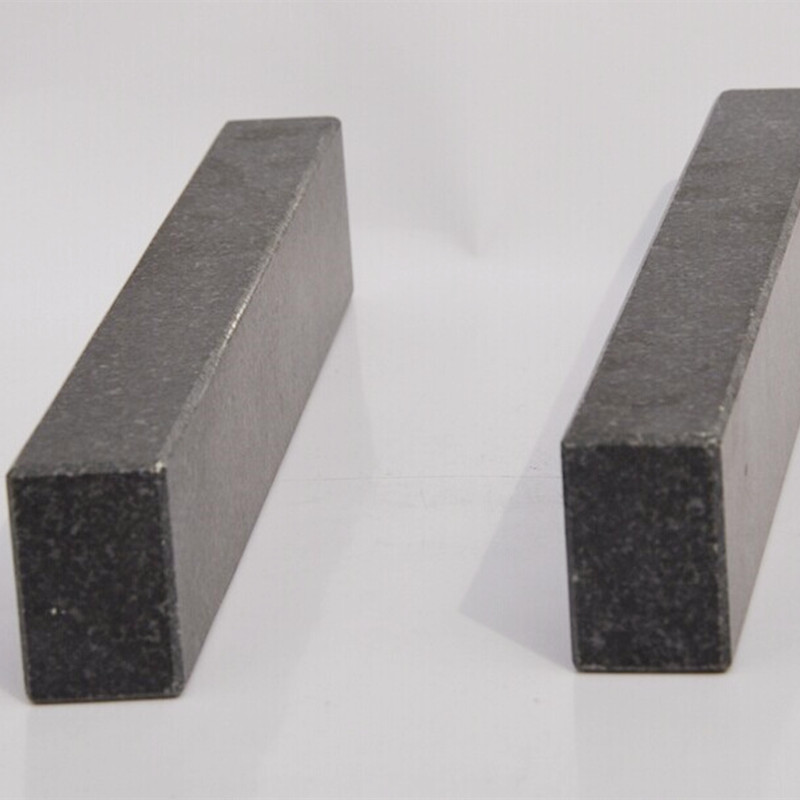

A gate valve operates by lifting a rectangular gate out of the path of the fluid flow. The design ensures that, when fully opened, there is minimal pressure drop across the valve, making it an efficient option for controlling flow in larger pipelines. The 160mm size makes it particularly effective in systems that require a substantial volume of fluid to be transmitted with minimal resistance.

The construction of a 160mm gate valve typically involves robust materials such as cast iron, stainless steel, or brass, depending on the specific requirements of the application

. The choice of material greatly influences the valve's overall durability, corrosion resistance, and suitability for different media, whether they are water, oil, or chemicals.Advantages of 160mm Gate Valves

1. Low Flow Resistance One of the primary benefits of using a gate valve is its ability to handle fluids with low resistance when fully open. This characteristic makes it ideal for use in systems where efficiency is paramount.

2. Versatile Applications The 160mm size allows the gate valve to be used in various sectors, including water treatment plants, chemical processing, oil and gas distribution, and HVAC systems. Its versatility is a significant advantage for engineers and operators.

160mm gate valve

3. Reliable Isolation Gate valves are designed to provide a tight seal when closed, which is essential for isolating sections of a pipeline during maintenance or in emergencies. This reliability minimizes the risk of leaks and ensures safety.

4. Ease of Operation Whether operated manually or with an actuator, gate valves are easy to use. Their straightforward design allows for quick adjustments to flow control without requiring sophisticated mechanisms.

Installation and Maintenance Considerations

Installing a 160mm gate valve requires careful planning to ensure that it fits the piping system and operates effectively. Proper alignment is crucial; misalignment can lead to premature wear or failure. Additionally, regular maintenance is necessary to ensure longevity and optimal performance. This includes routine inspections for wear and tear, checking for corrosion, and ensuring the sealing is intact.

Operators should be familiar with common issues that may arise, such as seat wear or obstruction caused by debris, which can impede the valve's functionality. Performing timely maintenance can mitigate these issues and maintain the valve's operation over time.

Conclusion

In summary, the 160mm gate valve is an essential component in various fluid handling systems, providing an efficient and reliable solution for flow regulation. Its low flow resistance, durability, and versatility make it an ideal choice for many industries. By understanding the design, advantages, and maintenance needs of the 160mm gate valve, operators can make informed decisions that enhance the efficiency and safety of their systems. As industries continue to evolve, the importance of reliable flow control devices like the gate valve cannot be overstated, highlighting the need for ongoing development and innovation in valve technology.

-

Y Type Strainer Applications in Industrial Water FiltrationNewsJun.19,2025

-

Portable Welding Workbenches for On-Site ProjectsNewsJun.19,2025

-

Plug Ring Gauge Applications in Automotive Quality ControlNewsJun.19,2025

-

How to Calibrate a Precision Spirit Level for AccuracyNewsJun.19,2025

-

A Comprehensive Guide to Valve TypesNewsJun.17,2025

-

Precision Quality Control with Ring GaugesNewsJun.17,2025

Related PRODUCTS