dec . 07, 2024 17:22 Back to list

use of thread gauge

The Use of Thread Gauges Ensuring Precision in Engineering

In the world of engineering, the accuracy and reliability of threaded connections are critical to the overall performance and safety of mechanical systems. One of the essential tools used to measure and verify the dimensions of threaded fasteners is the thread gauge. This article explores the importance, types, applications, and best practices for using thread gauges in various industries.

What is a Thread Gauge?

A thread gauge is a precision measuring instrument designed to check the dimensions and quality of threaded components, such as screws, bolts, and nuts. These gauges help ensure that the threads of a fastener meet specified standards, which is crucial for achieving proper fit and function. Usually crafted from high-quality materials, thread gauges offer durability and accuracy in measurement.

Importance of Thread Gauges

The significance of thread gauges cannot be overstated. In many engineering applications, the integrity of a threaded connection directly impacts the functionality and safety of the entire system. Improperly threaded components can lead to failures, which may pose serious risks, including equipment malfunction or catastrophic accidents.

For example, in the aerospace industry, where every component is subjected to rigorous safety standards, the use of thread gauges is a critical part of quality control. Engineers rely on these tools to ensure that threads are within specified tolerances, thereby enhancing the overall safety and reliability of aircraft systems.

Furthermore, the use of thread gauges contributes to cost-effectiveness in production. By ensuring high-quality threaded components during the manufacturing process, businesses can reduce waste and minimize the need for rework, which ultimately saves time and resources.

Types of Thread Gauges

There are several types of thread gauges, each designed for specific tasks

1. Go/No-Go Gauges These are the most common type of thread gauges, consisting of two ends. The Go end should fit onto the threaded component, confirming that it meets minimum size requirements, while the No-Go end should not fit, indicating that the thread is within the acceptable size range.

use of thread gauge

2. Pitch Gauges These gauges are used to measure the pitch (the distance between threads) of a screw or bolt. Proper pitch is essential for ensuring that components can be mated correctly, especially in assemblies involving multiple fasteners.

3. Thread Micrometers For applications requiring high precision, thread micrometers can measure the pitch diameter of a thread. This tool provides a more detailed assessment of the thread profile, helping engineers achieve tighter tolerances.

4. Thread Calipers These combined tools can measure various thread parameters, providing versatility in one gauge. They are particularly useful when inspecting larger components where multiple measurements may be needed.

Best Practices for Using Thread Gauges

To ensure accurate measurements and maintain the integrity of thread gauges, several best practices should be observed

1. Calibration Regular calibration of thread gauges is essential. This process ensures that the gauges maintain their precision and reliability over time. Calibration should be performed according to established standards and protocols.

2. Proper Handling Thread gauges should always be handled with care. Dropping or mishandling these tools can lead to damage and inaccuracies in measurement.

3. Regular Cleaning Dirt, oil, or debris on the threads can affect measurement. It is important to clean both the gauge and the threaded component before performing measurements.

4. Training Personnel involved in measuring threaded components should have adequate training on the correct use of thread gauges. Understanding how to read measurements and interpret results is vital for maintaining quality control.

Conclusion

Thread gauges are indispensable tools in the engineering field, ensuring that threaded components meet required quality standards. By using these gauges correctly and implementing best practices, engineers can enhance product reliability and safety while optimizing production processes. As technology advances, the tools available for measuring threaded components continue to improve, but the fundamental role of thread gauges remains critical in achieving precision in engineering.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

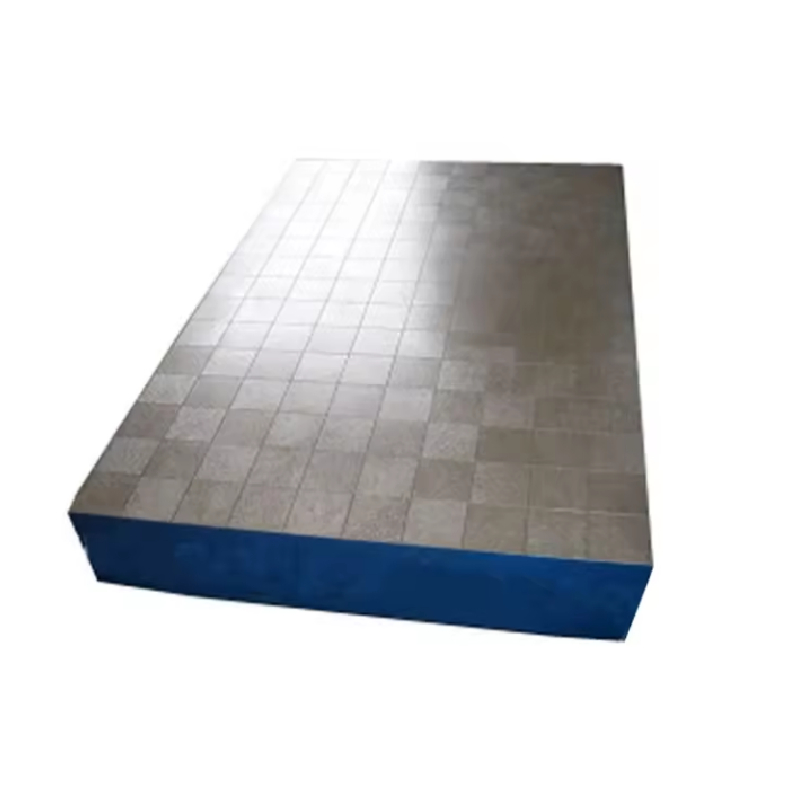

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS