nov . 01, 2024 00:52 Back to list

3% butterfly valve with actuator specifications and performance characteristics for optimal control

The 3% Butterfly Valve with Actuator A Vital Component in Fluid Control Systems

Butterfly valves are among the most widely used valves in industrial applications, known for their simple design, reliable performance, and efficient operation. The 3% butterfly valve with an actuator is a specific variant that holds significance in various fluid control systems. This article delves into its construction, operation, applications, and advantages.

Construction and Design

A butterfly valve consists of a rotating disk that regulates flow. The term 3% refers to the valve's design specification, which often indicates the flow coefficient or the amount of flow resistance in the valve. This parameter is crucial in applications requiring precise control over fluid dynamics. The valve is typically constructed from durable materials like stainless steel or ductile iron, which enhances its longevity and resilience against corrosive substances.

The addition of an actuator transforms a manual butterfly valve into an automated control solution. Actuators can be electric, pneumatic, or hydraulic, depending on the operational requirements. Electric actuators offer precise control and can be easily integrated into an automated system, making them ideal for applications requiring frequent adjustments. Pneumatic actuators are preferred in environments needing rapid response times.

Operation

The operation of a 3% butterfly valve with an actuator is straightforward yet effective. When the actuator receives a signal, it rotates the valve's disk, allowing or restricting flow. A 90-degree rotation can transition the valve from fully open to closed. The design ensures minimal pressure drop, which is a significant advantage in terms of energy efficiency.

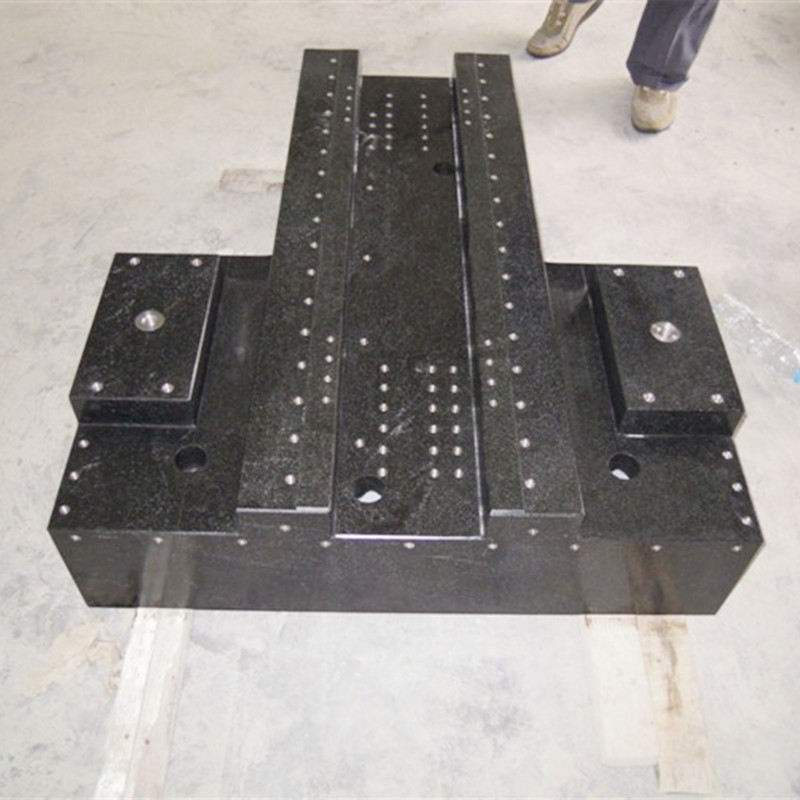

3 butterfly valve with actuator

The actuator can be equipped with feedback mechanisms to monitor valve position and ensure it operates according to the set parameters. This level of control is crucial in industries where consistency and precision are essential, such as in water treatment facilities, chemical processing plants, and HVAC systems.

Applications

The applications of a 3% butterfly valve with an actuator are extensive. In water supply systems, these valves regulate water flow efficiently, minimizing leaks and ensuring optimal pressure levels. The chemical industry employs them for handling various liquids and gases, thanks to their ability to withstand high pressures and corrosive substances. Additionally, in HVAC systems, these valves control airflow, thereby optimizing energy usage and enhancing overall system performance.

Advantages

There are several advantages to using a 3% butterfly valve with an actuator. Firstly, the design allows for quick opening and closing, which is essential in emergency shut-off scenarios. Secondly, the compact design helps save space, making it suitable for installations with limited room. Lastly, automating the valve with an actuator significantly reduces the need for manual intervention, leading to increased operational efficiency and reduced labor costs.

In conclusion, the 3% butterfly valve with an actuator is a crucial component in modern fluid control systems. Its efficient design, coupled with the benefits of automation, makes it a preferred choice for various industrial applications. As industries continue to seek more efficient fluid management solutions, the role of butterfly valves will undoubtedly grow, adapting to meet these evolving demands.

-

Heavy Duty Knife Gate Valve PerformanceNewsJul.25,2025

-

Choosing Between Gate and Globe Gate Valves for Optimal PerformanceNewsJul.25,2025

-

Cast Iron Y Strainer DurabilityNewsJul.25,2025

-

Ball Style Check Valve MaintenanceNewsJul.25,2025

-

Types of Strainer in Piping SystemsNewsJul.25,2025

-

The Role of Master Ring Gage in Quality Control SystemsNewsJul.25,2025

Related PRODUCTS