Optical Konpoze Imaj Nivo

Deskripsyon Product

- 1.Aplikasyon

Se nivo optik imaj konpoze lajman ki itilize nan mezire gradyan yo nan sifas plat ak sifas silendrik nan direksyon orizontal; Plan an ak straightness nan slideway oswa baz nan zouti machin oswa enstriman optik mekanik kòm byen ke kòrèkteman nan enstale pozisyon nan ekipman yo.

- 2.Done teknik

(1) chak valè gradyasyon:...0.01mm/m

(2) max mezi ranje:...0~10mm/m

(3) alokasyon:...1mm/nan yon sèl mèt... 0.01mm/m

Nan tout ranje mezire...0.02mm/m

(4) devyasyon avyon sou sifas travay...0.0003mm/m

(5) chak valè gradyasyon nivo lespri...0.1mm/m

(6) k ap travay sifas (LW):...165 48mm

(7) pwa nèt nan enstriman an: ... 2kgs.

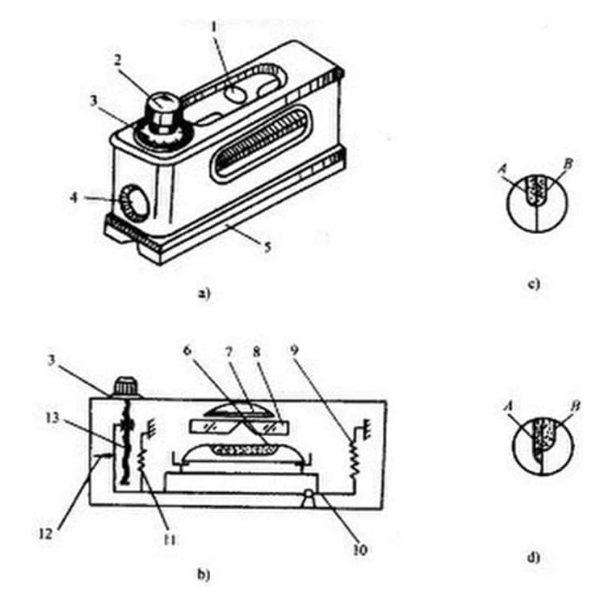

- 3.Estrikti enstriman an:

Nivo imaj konpoze sitou konsiste de pati sa yo tankou mikwo ajiste vis, nwa, disk gradye, nivo lespri, prism, loup, levye kòm byen ke baz ak sifas k ap travay plenn ak v.

- 4.Working prensip:

Nivo imaj konpoze a sèvi ak prism pou jwenn imaj ti wonn lè yo nan konpoze nivo lespri a ak agrandi pou amelyore presizyon lekti epi sèvi ak levye ak mikwo vis transmèt sistèm pou amelyore sansiblite lekti. Se poutèt sa, si moso nan travay ak yon gradyan nan 0.01mm / m, li ka avèk presizyon li nan nivo a imaj konpoze (nivo a lespri nan nivo a imaj konpoze sitou jwe wòl nan endike zewo).

- 5.Metòd operasyon:

Mete nivo a imaj konpoze sou sifas k ap travay nan moso travay la mezire ak gradyan an nan pyès la mezire lakòz enkonidans nan imaj yo ti wonn lè remoke; Vire disk gradye a jiskaske imaj ti wonn lè remoke yo kowenside epi li ka jwenn imedyatman. Ou ka kalkile gradyan aktyèl la nan moso travay la mezire pa fòmil sa a:

Aktyèl gradyan = valè gradyan distans Fulcrum Disk lekti

Egzanp Fox: Lekti disk: 5 gradyan; Kòm nivo imaj konpoze sa a se foxed ak valè gradyan li yo ak distans fulcrum, se sa ki valè gradyan: 0.01mm / m ak distans fulcrum: 165mm.

Se konsa: aktyèl gradyan = 165mm 5 0.01/1000 = 0.00825mm

- 6.Avi operasyon:

(1) anvan ou itilize, netwaye pousyè lwil la ak gazolin epi netwaye ak twal gaz absorbant.

(2) Chanjman tanperati a gen gwo enfliyans sou enstriman e se poutèt sa li dwe separe ak sous chalè pou evite erè.

(3) Pandan mezi, vire disk gradye a jiskaske imaj ti wonn lè remorquage yo konplètman kowenside epi apre sa yo ka pran lekti yo sou direksyon pozitif ak negatif.

(4) If the instrument is found with in correct zero position, it may be adjusted; Put the instrument on a stable table and rotate the graduated disc to set the tow air bubble images coincide to get first reading a; Then turn the instrument by 180o and put back to its original place. Ra-rotate the graduated disc to get the tow air bubbles coincide to get the second reading b. So 1/2 (α +β ) is the zero deviation of the instrument. Loosen the three supporting screws on the graduated disc and press lightly by hand the embossed adjusting cap; Rotate the disc by 1/2 (α +β) to get the zero deviation and the point line composite; At last fasten the screws.

(5) Apre travay, sifas k ap travay nan enstriman an dwe netwaye epi kouvwi ak asid gratis, anidrid, lwil oliv antirouye ak papye antiwouy; Mete l nan yon bwat an bwa epi estoke l nan yon kote ki pwòp sèk.

Hot Tags: Optical Composite Image Level Optical Composite Image Level suppliers China Optical Composite Image Level Optical Composite Image Level factory stable Optical Composite Image Level

Paramèt pwodwi

Paramèt teknik

- Plak valè rele 0.01 mm/m

- Ranje mezi 0-10 milimèt/mèt

- Parent-child error within ± 1mm/m+0.01 mm/m

- The parental error within the entire measurement range is ± 0. 02 millimeters/meter

- Devyasyon platite ban nan 0.003mm

- Valè selil akimilasyon estanda 0.1 milimèt/mèt

- Gwosè biwo biwo 165 x 48 milimèt

- Pwa nèt 2.2 kilogram

Optical Composite Image Level Maintenance: Antirust Oil & Storage Tips

Proper maintenance ensures your optical composite image level retains its 0.01mm/m precision and durability. Follow these steps to protect its prism technology and mechanical components:

1. Daily Cleaning for Surface Protection

After use, wipe working surfaces (V-groove, edges, lenses) with isopropyl alcohol on a lint-free cloth to remove oils and dust. Use a soft brush for stubborn debris—never abrasives, which can scratch optical parts or damage metal coatings. This preserves the precision ground surfaces (Ra ≤ 0.1μm) critical for accurate readings.

2. Routine Antirust Care for Metal Parts

While the granite base resists corrosion, metal components (screws, levers, hinges) need protection. Apply Storaen’s non-acidic anti-rust oil every 3 months or after moisture exposure:

Apply thinly to threads and pivots with a dropper, avoiding pooling on granite/lenses.

Prevents seizing: Maintains lever mechanism sensitivity (0.001mm precision) for cylindrical slope measurements.

3. Optimal Storage Practices

Store in the included hard case or a dry cabinet to avoid temperature/humidity damage:

Environment: 10°C–30°C, <60% humidity to prevent lens condensation and optical distortion.

Positioning: Lay flat or upright in padded slots; never under heavy objects to avoid misaligning the optical system.

Long-term storage: Reapply anti-rust oil and add a silica packet; inspect 24 hours before use, verifying zero position via 180° rotation calibration.

4. Monthly Functional Inspections

Check performance regularly to ensure reliability:

Bubble clarity: Confirm the composite bubble image aligns smoothly without blur.

Lever movement: Test micro-screws for smooth rotation—stiffness signals needed lubrication.

Flatness check: Use a reference plate to validate factory-calibrated flatness (±0.0003mm/m).

5. Storaen’s Support for Longevity

Leverage our expert services to maintain peak performance:

Factory recalibration: Restores 0.01mm/m precision via ISO-certified equipment for critical applications.

Genuine parts: Replacement components ensure compatibility and preserve original accuracy.

By following these steps, your Storaen optical composite image level will deliver consistent precision for industrial alignment tasks, backed by our 30+ years of engineering expertise.

Zero Position Calibration of Optical Composite Image Level: 180° Rotation Method Explained

Accurate zero calibration is vital for your Storaen optical composite image level to maintain its 0.01mm/m precision and ±0.0003mm/m flatness. The 180° rotation method eliminates subtle optical or mechanical shifts, ensuring reliable measurements in critical tasks like CNC machine alignment or aerospace component inspection. Here’s a streamlined, step-by-step guide:

1. Why Calibrate?

Impacts, vibrations, or temperature fluctuations can shift the level’s zero reference, leading to measurement drift. Calibration realigns the bubble vial with the tool’s optical prism and lever system, ensuring consistent baselines for industrial applications where 0.001mm deviations are unacceptable—such as verifying machine tool guides or structural frameworks.

2. Setup Requirements

Storaen optical composite image level (featuring a V-grooved base and micro-adjusting screw)

Certified precision reference flat (e.g., our Storaen granite surface plate, with flatness ≤0.0002mm/m)

A clean, vibration-free workbench in a temperature-stabilized environment (18°C–22°C recommended)

3. Step 1: Initial Measurement

Place the level lengthwise on the reference flat, aligning the V-grooved base with the flat’s central axis. Rotate the micro-adjusting screw until the composite bubble image—created by the 45° prism system—perfectly overlaps in the viewfinder. Record this initial scale reading (A), which reflects the current deviation from true zero.

4. Step 2: 180° Rotation & Second Reading

Carefully flip the level 180° end-to-end while maintaining its longitudinal orientation on the flat (avoid any lateral movement). Adjust the micro-screw again to align the bubble image and record the new reading (B). The difference Δ = |A - B| indicates zero position error; ideal values for Storaen levels should be ≤0.005mm/m.

5. Step 3: Error Correction & Verification

Calculate the target zero position as the midpoint: C = (A + B)/2. Loosen the protective cap on the zero-adjustment screw (typically located near the bubble vial), rotate the screw until the scale reads C, then retighten. Repeat Steps 3–4 until Δ ≤0.002mm/m, ensuring minimal residual error.

6. Pro Tips for Precision

Triple-Check Consistency: Perform 3 calibration cycles, especially after transporting the level or working in environments with temperature swings, to ensure repeatable results.

Lubricate Moving Parts: Apply a drop of Storaen’s non-acidic oil to the micro-screw before adjustment to ensure smooth, backlash-free operation and prevent binding.

Environmental Control: Avoid calibrating near heat sources or drafts, as even minor temperature gradients can affect the granite base’s dimensional stability and introduce errors.

7. Storaen’s Calibration Support

Every Storaen optical composite image level includes a NIST-traceable calibration certificate, but quarterly in-field checks are recommended for heavy use. Our support includes:

Factory Recalibration: Restoring original 0.01mm/m accuracy using laser interferometers for high-stakes applications.

Genuine Spare Parts: Readily available adjustment screws and maintenance kits for long-term usability.

Video Tutorials & Expert Guidance: Step-by-step videos and engineer support to assist with on-site calibration procedures.

Final Notes

Mastering the 180° rotation method ensures your Storaen optical composite image level delivers the precision required for cylindrical slope measurements, machine tool flatness checks, and other critical alignments. With proper calibration, this tool, backed by our 30+ years of engineering expertise, becomes an indispensable asset in your quality control workflow, ensuring every measurement is as reliable as the first.

Ki gen rapò PWODWI

Nouvèl ki gen rapò

Thread Plug Gauge Requires Careful Handling

In the world of manufacturing and engineering, precision is non-negotiable—especially when it comes to threads, which are critical components in machinery, construction, and everyday products.

Surface plate calibration

In today's world, where precision and accuracy are crucial in various industries, the use of granite inspection tables and granite surface plates has become increasingly popular.

Ring Gauge Ensures Machining Accuracy

In the world of precision engineering, manufacturing, and quality control, accuracy is the cornerstone of reliability.