Sep . 23, 2024 15:57 Back to list

Choosing the Right Stone Surface Plate for Precision Measurement Needs

The Importance of Stone Surface Plates in Precision Measurement

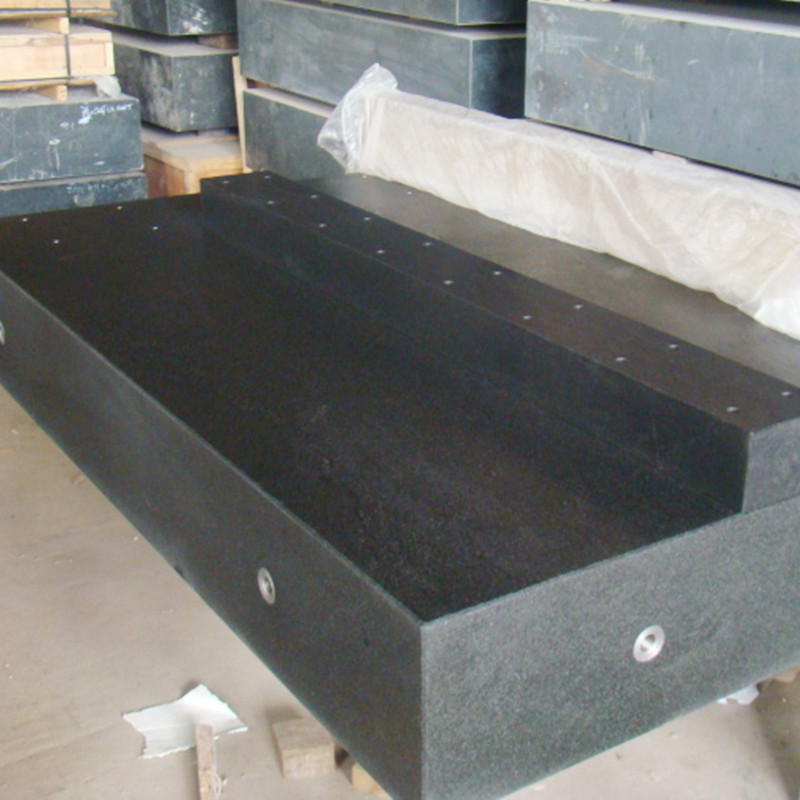

In the realm of precision engineering and manufacturing, the accuracy of measurements is paramount. One of the crucial tools that facilitate this precision is the stone surface plate. These plates, typically made from high-quality granite, play a pivotal role in achieving exact measurements and ensuring the reliability of various machining processes.

Stone surface plates serve as a flat reference surface against which parts and components can be measured. The fundamental property of a surface plate is its flatness, which is often within a tolerance of a few microns. This high degree of flatness is essential for tasks like calibrating measuring instruments and checking the accuracy of machined parts. When engineers and machinists are tasked with creating high-precision components, the stone surface plate becomes their best ally, offering a stable and reliable foundation for measurements.

Granite is favored for surface plates because of its unique properties. It is inherently stable and resists warping or deformation, making it an ideal material for a tool that must maintain strict tolerances over time. Additionally, granite has a low coefficient of thermal expansion, which means it can maintain its flatness even with temperature fluctuations. This stability is crucial in environments where machining processes generate heat, potentially altering the dimensions of both the workpiece and the measuring tools.

stone surface plate

Another significant advantage of stone surface plates is their durability. These plates are resistant to scratching and wear, allowing them to provide years of reliable service with proper care. Furthermore, their surface can be easily cleaned, ensuring that contaminants do not interfere with measurement precision. Regular maintenance, such as cleaning and periodic re-calibration, helps preserve their accuracy, ensuring they meet the stringent demands of precision engineering.

In addition to their measuring capabilities, stone surface plates are also central to various inspection processes. They are often used in conjunction with other measuring instruments, such as calipers, micrometers, and dial indicators, enabling technicians to achieve consistent and reliable results. Furthermore, these plates can serve as a base for assembling and inspecting parts, enhancing productivity and ensuring that components meet required specifications.

In conclusion, stone surface plates are indispensable tools in precision measurement and quality control within the manufacturing sector. Their unparalleled flatness, durability, and stability make them vital for ensuring that parts are manufactured to exacting standards. As industries continue to evolve and the demand for precision increases, the importance of stone surface plates in achieving quality and accuracy cannot be overstated.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS