Nov . 13, 2024 07:44 Back to list

micrometer tools

Understanding Micrometer Tools Precision in Measurement

Micrometer tools, often referred to simply as micrometers, are essential instruments in the fields of engineering, manufacturing, and metalworking. These tools are designed to measure small dimensions with an incredible level of accuracy, making them indispensable in quality control and precision machining. In this article, we explore the various aspects of micrometer tools, their types, usage, and importance in various industries.

What is a Micrometer?

A micrometer is a precise measuring instrument that can measure dimensions with high accuracy, typically within the range of 0.01 mm (or 0.001 inches). The fundamental operation of a micrometer relies on the principle of a screw mechanism, where the rotation of a screw moves a spindle and anvil closer or further apart, allowing for the measurement of an object's thickness, diameter, or length.

Types of Micrometers

There are several types of micrometers, each designed for specific measurement applications

1. Outside Micrometer This most common type of micrometer measures the outer dimensions of an object. For instance, it can be used to measure the diameter of wires or the thickness of mechanical parts.

2. Inside Micrometer Contrary to the outside micrometer, the inside micrometer is used to measure the internal dimensions of an object, such as the diameter of a hole or tube. This tool typically features an adjustable rod for accurate internal measurements.

3. Depth Micrometer Designed to measure the depth of holes or grooves, depth micrometers are equipped with a flat base and a measuring rod. The measurement is obtained by placing the base on the surface and extending the rod into the hole.

4. Bench Micrometer This is a variation used for more extensive measurements and is often mounted on a bench. It can be used in laboratories for research or in manufacturing settings for testing parts.

5. Digital Micrometer An advancement in technology has led to the creation of digital micrometers which provide a digital readout of measurements. This eliminates the chances of human error in reading measurements and often allows for more efficient data recording.

How to Use a Micrometer

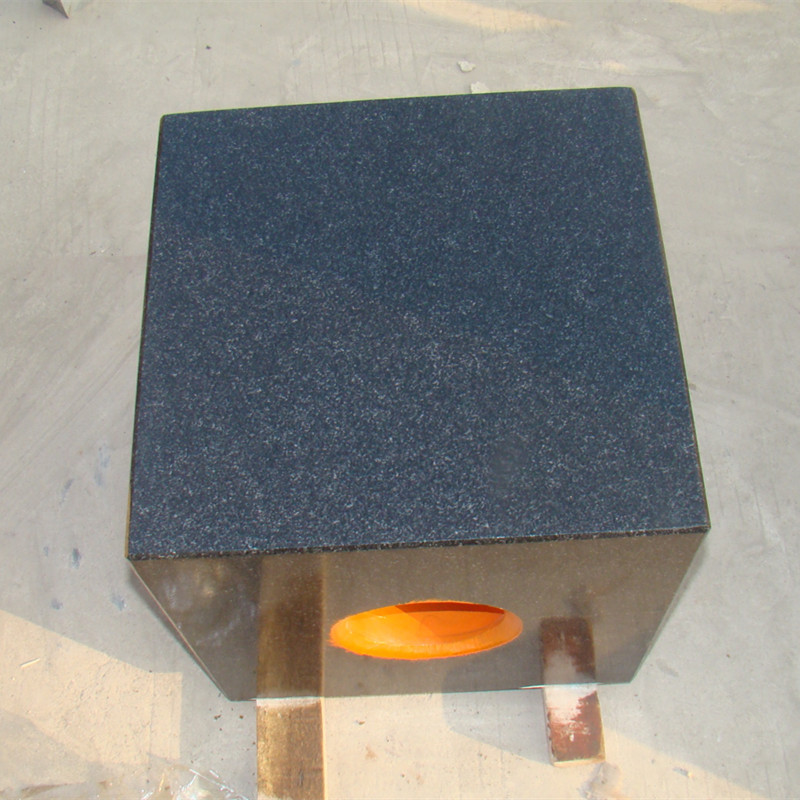

micrometer tools

Using a micrometer is straightforward, yet it requires some attention to detail for ensuring accurate measurements. Here’s a basic guide on how to use one

1. Zeroing the Micrometer Before measuring, check that the micrometer reads zero when fully closed. This is crucial for ensuring measurement accuracy.

2. Placing the Object Place the object to be measured between the anvil (the stationary part) and the spindle (the movable part) of the micrometer.

3. Applying Pressure Gently rotate the thimble until the spindle contacts the object. Avoid excessive force, as it can lead to damaging the object or affecting accuracy.

4. Reading the Measurement After securing the object, read the measurement on the scale. For models with a digital display, simply read the value shown.

5. Recording the Measurement Write down your reading immediately to ensure you don’t forget any important measurements, especially if you're working on multiple tasks.

Importance in Industries

The significance of micrometer tools cannot be overstated, especially in industries where precision is paramount. In manufacturing, micrometers are crucial for creating parts that fit together seamlessly — a necessary requirement for safety and functionality, especially in aerospace and automotive industries. In research and development, these tools ensure that experimental results are as accurate as possible, facilitating the advancement of science and engineering.

Furthermore, micrometers are instrumental in quality assurance processes, where meticulous measurement is vital to maintain standards and specifications. Their role in craftsmanship can also be appreciated in woodworking and metalworking, where artisans ensure that every measurement is exact.

Conclusion

Micrometer tools represent a blend of engineering precision and innovation. Their ability to provide detailed measurements makes them critical in a variety of environments, from bustling manufacturing floors to clean laboratory settings. Understanding how to properly use and maintain these instruments not only enhances measurement practices but also contributes to the overall quality of industrial and experimental work. Thus, investing in quality micrometers and mastering their use is an essential step toward achieving excellence in various fields where precision is a hallmark of success.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS