May . 30, 2025 16:58 Retounen nan lis la

Material Selection and Durability in Heavy-Duty Welding Table Workbenches

In industrial manufacturing and fabrication, the durability of welded steel workbenches, welding table workbenches, and round welding tables directly impacts productivity, safety, and long-term costs. For wholesalers supplying these critical tools, understanding material science and design principles is essential to meet the demands of high-volume buyers. This article explores how material choices influence the performance of heavy-duty workbenches, offering actionable insights for bulk procurement strategies in sectors like automotive, aerospace, and metal fabrication.

Welded Steel Workbenches: Balancing Strength and Cost for Bulk Buyers

Welded steel workbenches are the backbone of workshops, valued for their ruggedness and adaptability. However, not all steel is created equal. For wholesalers, selecting the right grade and thickness is critical. Carbon steel is a common choice due to its high tensile strength and affordability. Thicker gauges (12–10 gauge) resist warping under heavy loads, making them ideal for assembly lines or machining stations.

To enhance durability, many manufacturers apply powder coatings or galvanized finishes to welded steel workbenches, protecting against rust in humid environments. Wholesalers must prioritize suppliers offering these treatments, as bulk buyers in industries like shipbuilding or construction require workbenches that withstand harsh conditions. Additionally, modular designs with reinforced leg braces or cross-members extend lifespan, reducing replacement frequency for clients.

Welding Table Workbenches: Heat Resistance and Longevity in High-Volume Settings

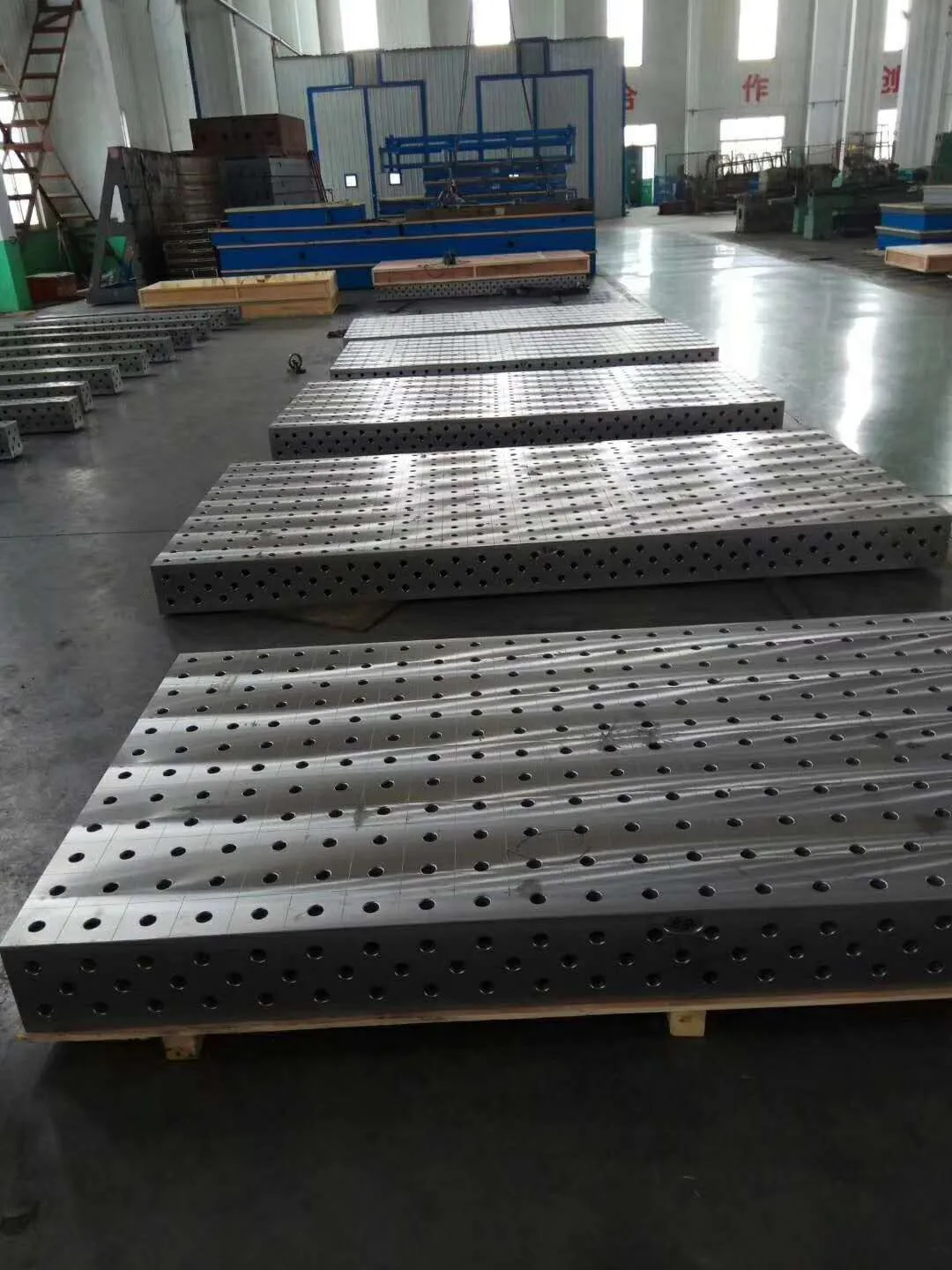

Unlike general-purpose welded steel workbenches, welding table workbenches are engineered to endure extreme heat, spatter, and repeated thermal cycling. The tabletops often use ½-inch to 1-inch thick steel plates with fire-resistant coatings like ceramic or copper. These materials dissipate heat quickly, preventing warping and extending the work surface’s usability.

For wholesalers, the challenge lies in balancing heat resistance with cost efficiency. Stainless steel variants offer superior corrosion resistance but are pricier—making them a harder sell for bulk buyers unless targeting niche markets like chemical plants. A cost-effective compromise is carbon steel tops with replaceable spatter-resistant mats, which can be bundled in bulk orders. Compatibility with modular clamping systems also adds value, allowing clients to customize setups without damaging the table’s surface.

Round Welding Tables: Specialized Materials for Rotational Fabrication Demands

Round welding tables are indispensable for projects requiring 360° access, such as pipe welding or circular fabrications. Their unique design demands materials that combine rotational stability with heat tolerance. Tabletops are often crafted from thick carbon steel (14–12 gauge) with laser-cut precision holes for clamps and fixtures. Some high-end models use aluminum alloys for lighter weight, though this sacrifices some heat resistance.

Wholesalers should note that round welding tables frequently require additional coatings to handle concentrated heat zones. Nickel or chrome plating on the table’s surface can reduce spatter adhesion, simplifying cleanup for bulk buyers in high-throughput environments like automotive exhaust manufacturing. Reinforced pedestal bases with anti-vibration pads are another selling point, ensuring stability during heavy grinding or cutting tasks.

Best Practices for Wholesalers Sourcing Durable Welded Steel Workbenches

Prioritize Certifications: Source welded steel workbenches and welding table workbenches compliant with ISO 9001 (quality management) and ANSI/ESD S20.20 (electrostatic discharge standards) for regulated industries.

Negotiate Custom Bulk Orders: Partner with manufacturers to offer tailored dimensions or coatings, such as anti-static finishes for electronics assembly workbenches.

Emphasize Total Cost of Ownership : Educate buyers on how premium materials reduce long-term costs via lower maintenance and longer replacement cycles.

Leverage Modularity: Stock round welding tables with compatible accessories (e.g., rotating turntables) to upsell complementary products in bulk deals.

By aligning with these strategies, wholesalers position themselves as partners in their clients’ operational efficiency.

FAQ: Addressing Key Concerns in Welding Table Workbench

What material is best for welding table workbenches in high-heat environments?

Thick carbon steel with ceramic coatings offers optimal heat resistance and durability. For extreme conditions, stainless steel tops are preferred but come at a higher cost.

Can round welding tables support heavy cylindrical components?

Yes. Look for round welding tables with reinforced steel bases.Modular designs with adjustable arms enhance stability for irregularly shaped parts.

How do I prevent rust on welded steel workbenches in humid climates?

Choose workbenches with galvanized or powder-coated finishes. For bulk buyers, suppliers often offer discounted rates on rust-inhibiting spray bundles for ongoing maintenance.

Are custom-sized welding table workbenches cost-effective for bulk orders?

Yes. Manufacturers typically reduce per-unit costs for large custom batches. Specify standardized hole patterns or coatings to keep production efficient.

What certifications should wholesalers verify when sourcing welding table workbenches?

Ensure compliance with quality, safety, and durability. These assure bulk buyers of reliability and regulatory adherence.

For wholesalers, the material selection of welded steel workbenches, welding table workbenches, and round welding tables is a strategic decision that impacts client satisfaction and repeat business. By prioritizing high-grade materials, protective coatings, and modular designs, distributors can deliver solutions that withstand industrial demands while maximizing ROI for bulk buyers. In an era where efficiency and durability are non-negotiable, wholesalers who master material science will dominate the market, forging long-term partnerships with manufacturers and fabricators alike.

-

Why the Right Angle Ruler Reigns in MetalworkingNouvèlJul.21,2025

-

The Enduring Allure of Granite Boxes in Modern InteriorsNouvèlJul.21,2025

-

The Digital Gauging Revolution: Reshaping Thread Rings Inspection's FutureNouvèlJul.21,2025

-

How Modern Inspection Platforms Transcend Surface MeasurementNouvèlJul.21,2025

-

How Customization Drives Wholesale Success in Parallel RulersNouvèlJul.21,2025

-

Fortifying Permanent Steel Ground Anchors Against Corrosion's OnslaughtNouvèlJul.21,2025

PWODWI ki gen rapò