Nov . 29, 2024 18:41 Back to list

magnetic v block working

The Working Principles and Applications of Magnetic V Blocks

Magnetic V blocks are indispensable tools in the field of machining and metalworking. They are primarily designed to clamp and hold workpieces securely in place during processes such as grinding, milling, and drilling. Their unique design, which incorporates strong permanent magnets, allows them to provide a stable and consistent base for various machining operations. In this article, we will explore the working principles of magnetic V blocks, their applications, and why they are essential in the workshop.

Understanding the Design

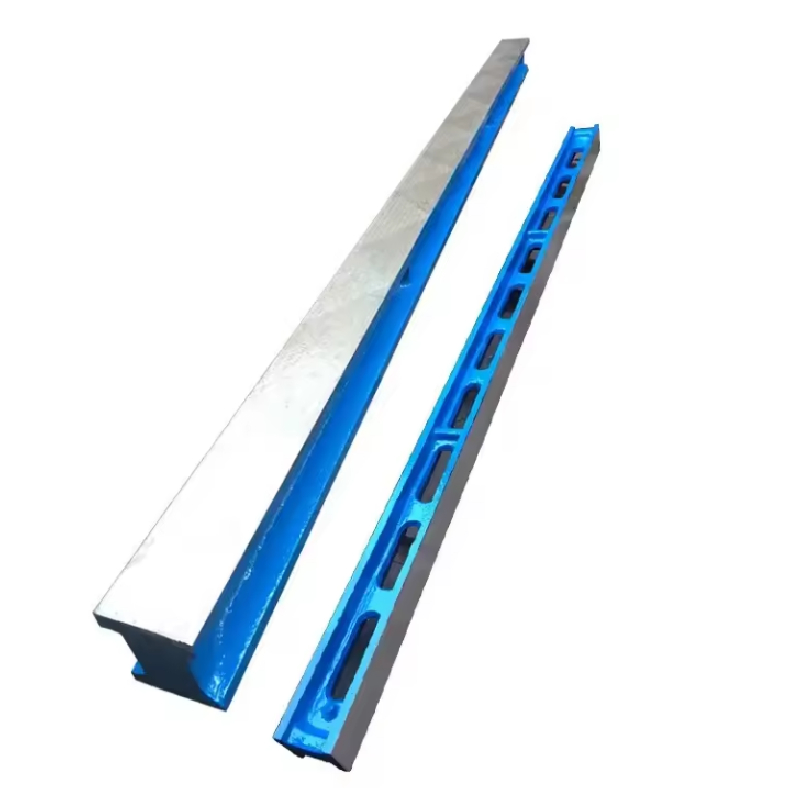

The design of a magnetic V block features two opposing V-shaped grooves, which are aligned to hold cylindrical workpieces securely. The blocks are made from high-strength materials, ensuring durability and resistance to wear and tear. The incorporated magnets provide a significant clamping force that can hold heavy workpieces without shifting, enabling precision in machining tasks.

The V block is typically configured with a toggle switch or lever, which activates the magnets. When engaged, the magnets create a powerful magnetic field that adheres the block to the work surface, as well as the workpiece to the block. This simplicity in the design is what makes magnetic V blocks an essential tool in various machining centers.

Operating Principles

The working principle behind magnetic V blocks relies on the magnetic force produced by permanent magnets or electromagnets. The clamping action can be categorized as follows

1. Permanent Magnetic Force Permanent magnets are designed to produce a consistent force without the need for an external power source. These magnets are usually made from materials like neodymium or ferrite, providing strong holding power aligned with minimal energy needs.

2. Electromagnetic Force In some advanced models, electromagnets are used. These require a power supply and can offer adjustable holding strength. This feature allows users to control the magnetic force, providing versatility for different workpiece sizes and materials.

To use a magnetic V block, the operator places the workpiece within the V grooves and activates the magnetic clamp. This secure holding allows for precise machining without the risk of movement, which could lead to dimensional inaccuracies or surface damage.

Applications

magnetic v block working

Magnetic V blocks are versatile tools with numerous applications across various industries

. Here are some notable uses1. Precision Machining In workshops and manufacturing environments, magnetic V blocks are used to hold cylindrical and irregularly shaped parts securely for grinding, milling, and drilling.

2. Inspection In quality control, magnetic V blocks provide a stable base for measuring instruments, allowing for accurate inspections of machined components.

3. Welding Magnetic V blocks can also assist in welding processes by providing a stable fixture for parts that need to be held at specific angles during the welding operation.

4. Assembly In assembly lines, these blocks can aid in the precise alignment of components before they are fastened, ensuring that assemblies are accurate and functional.

5. Maintenance and Repair They are helpful in maintenance tasks where technicians need to secure parts for inspection or repairs, offering a steady hand during complex procedures.

Benefits of Using Magnetic V Blocks

One of the most significant advantages of magnetic V blocks is their ability to enhance productivity and accuracy. By securely holding the workpiece in place, they reduce the likelihood of errors caused by vibration or movement during machining.

Furthermore, using magnetic V blocks contributes to safety in the workshop. A secure hold ensures that sharp or heavy materials do not shift unexpectedly, minimizing the risk of accidents.

In conclusion, magnetic V blocks are vital tools in the machining and metalworking industries. Their robust construction, combined with the principles of magnetism, makes them effective for a wide range of applications. By utilizing these blocks, operators can enhance precision, improve safety, and ultimately increase productivity in their machining processes. As technology evolves, the designs and capabilities of magnetic V blocks will likely advance, further solidifying their role as essential tools in modern manufacturing and engineering.

-

Thread Plug Gauge Our Promise of Measurement ExcellenceNewsAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyNewsAug.22,2025

-

Check Valve Types for High Rise BuildingsNewsAug.22,2025

-

Water Control Valve for Irrigation SystemsNewsAug.22,2025

-

Gate Valve with Soft Seal TechnologyNewsAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsNewsAug.22,2025

Related PRODUCTS