Jan . 24, 2025 05:11 Back to list

Soft Seal Gate Valve

The 150mm knife gate valve represents a crucial component in various industrial applications, offering efficiency and reliability in controlling fluid flow. This valve, with its unique specifications and advantages, addresses complex operational challenges across industries such as water treatment, mining, and chemical processing.

The authoritativeness of this valve type is underscored by its adherence to stringent industry standards. Compliance with standards such as ISO, API, and MSS ensures that these valves meet international safety, durability, and efficiency criteria. Manufacturers often highlight their compliance as a certification of quality, giving consumers confidence in their choice of valve. For businesses seeking to optimize their fluid control systems, the trustworthiness of the 150mm knife gate valve is paramount. Suppliers with a proven track record of providing reliable and efficient valve solutions are preferred. Testimonials and case studies from other companies in similar industries can serve as valuable endorsements, demonstrating the valve's performance and reliability in real-world conditions. Implementing a knife gate valve also involves considering the total cost of ownership. While the initial investment might be significant, the reduction in maintenance downtime, the extended lifespan of system components, and energy savings realized from efficient valve operation all contribute to long-term savings. A critical point in selecting the right valve is understanding the precise requirements of your application. Consulting with industry experts or engineers who can analyze the system’s specifics will ensure the valve's optimal performance. Discussing factors such as flow rate, pressure, and media type will help pinpoint the exact specifications needed, from material choice to blade design and actuation type. In summary, the 150mm knife gate valve is not merely a component but a strategic investment in operational efficiency and reliability. Its design and material adaptability cater to a wide range of challenging environments, enabling industries to maintain robust fluid control mechanisms. By choosing a valve that aligns with precise application needs and is backed by reputable manufacturers, companies position themselves for success in maintaining efficient and lower-risk operations.

The authoritativeness of this valve type is underscored by its adherence to stringent industry standards. Compliance with standards such as ISO, API, and MSS ensures that these valves meet international safety, durability, and efficiency criteria. Manufacturers often highlight their compliance as a certification of quality, giving consumers confidence in their choice of valve. For businesses seeking to optimize their fluid control systems, the trustworthiness of the 150mm knife gate valve is paramount. Suppliers with a proven track record of providing reliable and efficient valve solutions are preferred. Testimonials and case studies from other companies in similar industries can serve as valuable endorsements, demonstrating the valve's performance and reliability in real-world conditions. Implementing a knife gate valve also involves considering the total cost of ownership. While the initial investment might be significant, the reduction in maintenance downtime, the extended lifespan of system components, and energy savings realized from efficient valve operation all contribute to long-term savings. A critical point in selecting the right valve is understanding the precise requirements of your application. Consulting with industry experts or engineers who can analyze the system’s specifics will ensure the valve's optimal performance. Discussing factors such as flow rate, pressure, and media type will help pinpoint the exact specifications needed, from material choice to blade design and actuation type. In summary, the 150mm knife gate valve is not merely a component but a strategic investment in operational efficiency and reliability. Its design and material adaptability cater to a wide range of challenging environments, enabling industries to maintain robust fluid control mechanisms. By choosing a valve that aligns with precise application needs and is backed by reputable manufacturers, companies position themselves for success in maintaining efficient and lower-risk operations.

Next:

Latest news

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

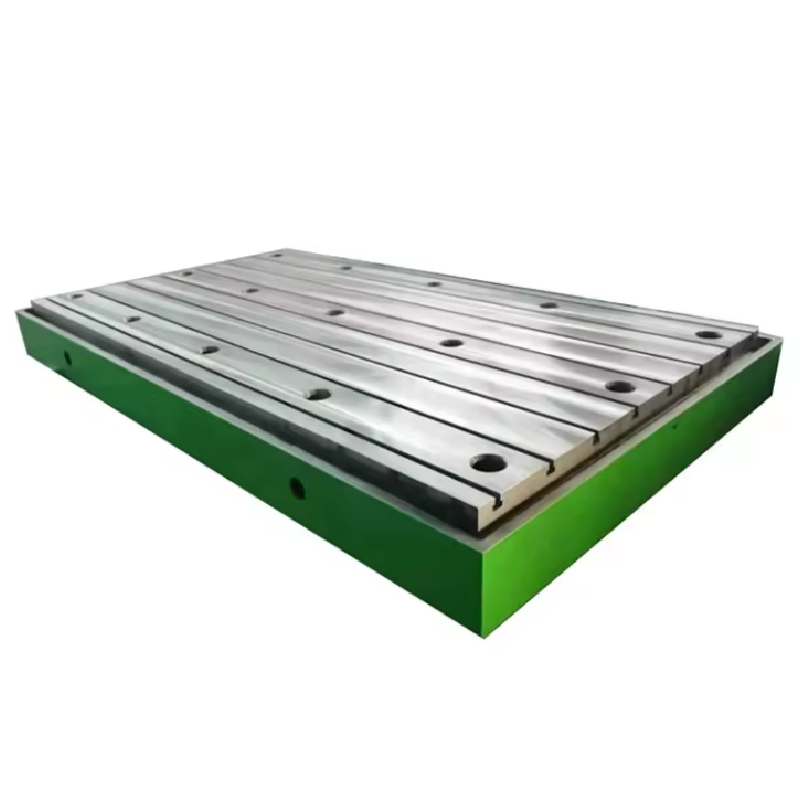

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS