נוב . 04, 2024 02:30 Back to list

thread pin gauge

Understanding Thread Pin Gauges An Essential Tool for Precision Engineering

In the realm of precision engineering, ensuring the accuracy of threaded components is critical. One of the essential tools utilized for this purpose is the thread pin gauge. This tool is designed to evaluate the dimensional accuracy of threaded holes and to verify that the threads conform to specified standards. A thread pin gauge serves not only as a quality control instrument but also as a means to guarantee the performance and durability of mechanical systems in which these components are employed.

A thread pin gauge consists of a series of pins, each having a specific diameter that corresponds to the effective pitch diameter of a range of standard thread sizes. These pins are categorized based on their size and form part of a comprehensive set that manufacturers or engineers use to check the thread pitch, size, and form. The typical gauges are made of high-strength materials such as steel to withstand wear and tear, ensuring a long tool life.

The primary function of a thread pin gauge is to perform a go/no-go test on threaded holes

. The go pin should fit easily within the threaded hole, indicating that the thread is adequate and within the acceptable tolerance range. Conversely, the no-go pin should not fit; if it does, this indicates an over-tolerance condition that may lead to improper mating with other threaded components. This binary testing method allows engineers to maintain stringent quality control, ensuring that all parts meet required specifications.thread pin gauge

The application of thread pin gauges extends across various industries, including automotive, aerospace, and manufacturing. In automotive engineering, for instance, the precision of threaded bolts and screws in engines and assemblies is paramount for vehicle safety and performance. Similarly, in aerospace, the reliability of threaded components can mean the difference between success and failure during critical flight operations. Thread pin gauges provide the necessary assurance to uphold these standards.

Moreover, as technology advances, so does the complexity of the components being produced. CNC machining and other automated manufacturing processes require equally precise tools for measuring and evaluating threaded features. Thread pin gauges must therefore adapt, with some models incorporating digital readouts for enhanced accuracy and ease of use.

Finally, the importance of proper calibration of thread pin gauges cannot be overstated. Regular checks against standardized reference materials ensure the gauges provide accurate measurements. This practice not only maintains the reliability of the gauges but also upholds the integrity of the entire production process.

In conclusion, thread pin gauges are indispensable in the assurance of the quality and functionality of threaded components. By providing a straightforward yet effective method for verifying thread accuracy, these tools play a crucial role in various industries where precision is paramount. Investing in high-quality thread pin gauges and adhering to rigorous calibration standards can vastly enhance the reliability and durability of engineered products.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

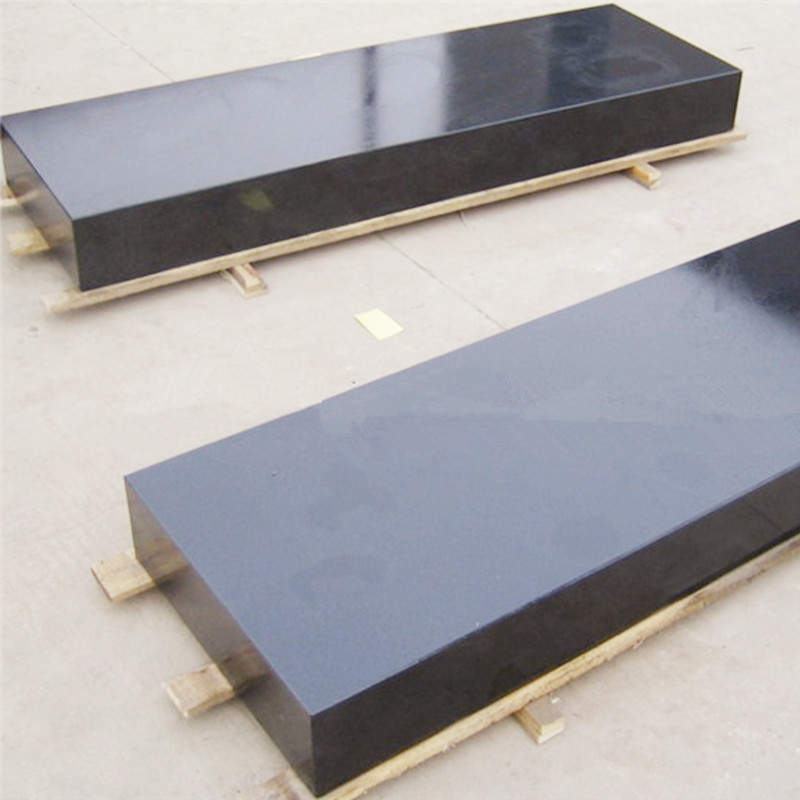

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS