נוב . 25, 2024 14:50 Back to list

taper plug gauge is used for checking

The Importance of Taper Plug Gauges in Precision Measurement

In the realm of engineering and manufacturing, precision is paramount. Components must fit together perfectly to ensure the functionality and longevity of machines and products. One of the critical tools used in this quest for accuracy is the taper plug gauge. This article will explore what taper plug gauges are, how they are used, and why they are vital in various industries.

Understanding Taper Plug Gauges

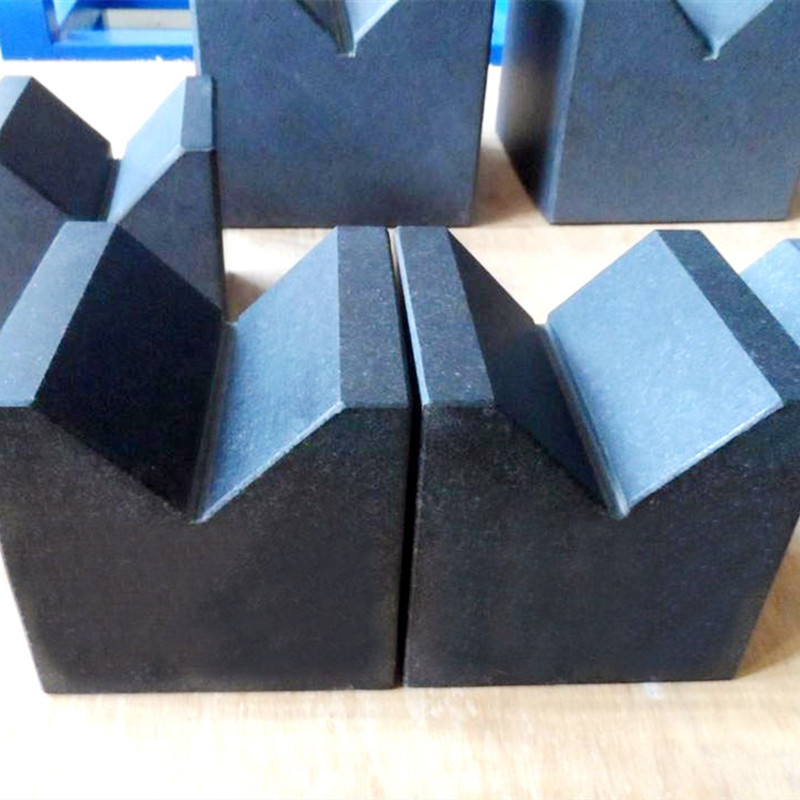

A taper plug gauge is a precision measuring instrument designed to check the dimensional accuracy of tapered holes in various components. Typically made of high-grade steel, these gauges feature a tapered shape that corresponds to the specifications of the hole being checked. The gauge is inserted into the hole, and the fit—or lack thereof—indicates whether the hole is within tolerance limits.

Taper plug gauges come in various sizes and taper angles, and they may be categorized as either go or no-go gauges. A “go” gauge must fit into the hole if the component is made correctly, while a “no-go” gauge must not fit. This binary testing method is straightforward and effective, providing a quick assessment of a component's dimensional integrity.

Applications in Various Industries

Taper plug gauges are widely used across several sectors, including aerospace, automotive, and manufacturing. In the aerospace industry, for example, the precise fit of components is essential for safety and performance. Tapered holes often accommodate fastening systems, and any deviations from specified dimensions could lead to catastrophic failures. Thus, taper plug gauges are an integral part of quality assurance processes.

taper plug gauge is used for checking

In the automotive sector, these gauges are used to ensure that engine components, transmission systems, and other crucial parts meet stringent specifications. Given the high-performance nature of automotive applications, any miscalculation can result in reduced efficiency or, worse, accidents. Taper plug gauges help manufacturers maintain high standards of quality.

In manufacturing settings, taper plug gauges facilitate the mass production of parts that must all adhere to exact specifications. When working with molds and dies, for example, a taper plug gauge can quickly determine if the manufactured items meet the required tolerances.

Ensuring Quality Control

The use of taper plug gauges is part of a broader quality control strategy that includes various measuring tools and techniques. Regular inspection of components using these gauges ensures compliance with industry standards and specifications. Any deviations can prompt corrective actions, whether that involves adjusting the manufacturing process or re-evaluating the design.

Moreover, taper plug gauges contribute to cost-effectiveness. By minimizing the risk of defective parts, manufacturers can reduce waste and downtime, ultimately enhancing productivity. Investing in high-quality taper plug gauges can yield significant returns through improved efficiency and reliability.

Conclusion

In summary, taper plug gauges are indispensable instruments in the field of precision measurement. Their ability to quickly and accurately assess the dimensions of tapered holes ensures that components fit together correctly, aiding in the overall quality control process. Whether in aerospace, automotive, or manufacturing, the role of these gauges cannot be overstated. As industries continue to evolve and demand higher standards, the importance of reliable measuring tools like taper plug gauges will only grow. By utilizing such gauges, companies not only adhere to stringent requirements but also foster innovation and excellence in production practices.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS