אוק . 01, 2024 09:52 Back to list

Understanding the Functionality and Benefits of Balloon Check Valves in Fluid Systems

Understanding the Balon Check Valve Mechanisms and Applications

In industrial applications where fluid flow management is essential, check valves play a critical role in maintaining the integrity of systems. Among various types of check valves, the Balon check valve stands out for its performance and reliability. This article delves into the mechanisms, features, advantages, and common applications of Balon check valves, emphasizing their importance in various industries.

What is a Balon Check Valve?

A Balon check valve is a specific kind of one-way valve that allows fluid to flow in only one direction, preventing backflow and ensuring that the system functions smoothly. Designed for durability and efficiency, Balon check valves are constructed using high-quality materials, making them suitable for a wide range of applications, including oil and gas, water treatment, and chemical processing.

Mechanism of Operation

The operation of a Balon check valve is based on a simple yet effective mechanism. It incorporates a disc or a ball that moves within the valve body. When fluid flows in the intended direction, the pressure pushes the disc or ball away from the opening, allowing flow to pass. Conversely, if there is a drop in pressure or reverse flow, the disc or ball is pushed back to its original position, sealing the valve and preventing any backflow. This self-acting mechanism eliminates the need for external control systems, making Balon check valves both efficient and cost-effective.

Key Features

1. Robust Construction Balon check valves are often constructed from materials such as stainless steel, carbon steel, or special alloys, providing excellent resistance to corrosion and wear. This durability extends the service life of the valve.

2. Variety of Designs They are available in several designs, including swing check, lift check, and ball check valves, allowing for adaptability in various systems and conditions.

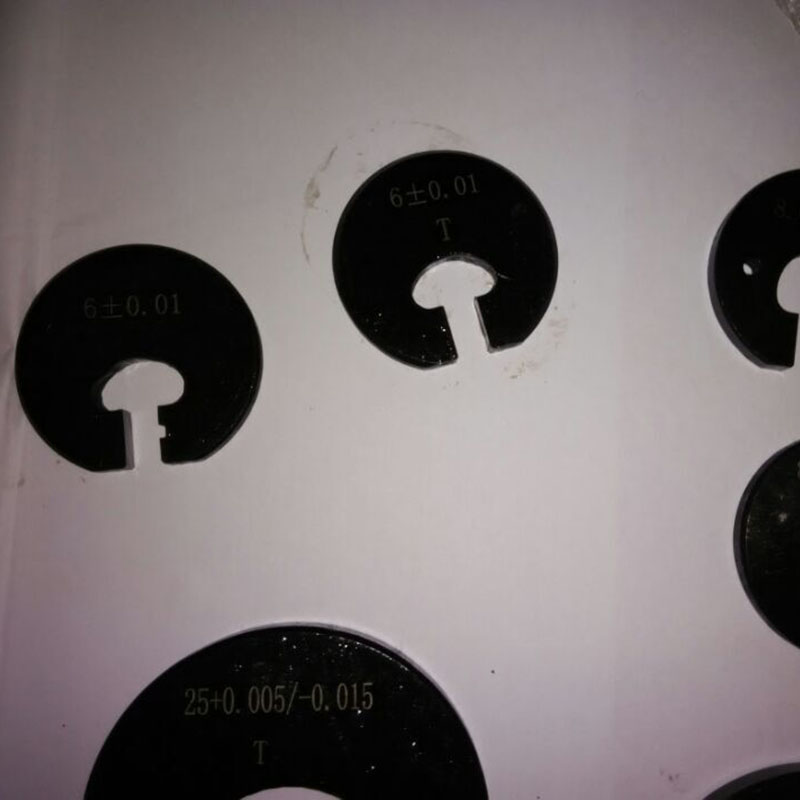

balon check valve

4. Compact Size Their compact design allows for easy installation in tight spaces, which is particularly beneficial in modular installations.

5. Minimal Maintenance With their simple mechanisms, Balon check valves require minimal maintenance, reducing operational costs and downtime.

Advantages

The advantages of using Balon check valves are manifold. The prevention of backflow not only protects equipment and components from damage caused by reverse flow but also enhances system efficiency by maintaining optimal flow conditions. Furthermore, the reliable sealing mechanism ensures that there is no leakage, which can lead to environmental hazards and material loss.

Applications

Balon check valves are widely used across several industries. In the oil and gas sector, they protect pipelines and storage facilities from potential backflows that could lead to catastrophic failures. In water treatment facilities, these valves help manage the flow of water and prevent contamination. They are also critical in chemical processing, where preventing backflow can protect sensitive compounds and systems from explosive reactions or contamination.

Conclusion

In conclusion, Balon check valves are a vital component in the management of fluid flow in various industrial applications. Their robust construction, effective operation, and versatility make them an ideal choice for ensuring the integrity and efficiency of fluid systems. As industries continue to evolve and demand higher standards for safety and performance, the role of reliable components like Balon check valves will only become more significant. Investing in quality check valves means investing in the longevity and reliability of operational systems, ultimately contributing to operational excellence and efficiency in industrial processes.

-

Wear Resistance Strategies for Trapezoidal ThreadsNewsJun.26,2025

-

Selecting Thread Gauge Types for Aerospace Component InspectionsNewsJun.26,2025

-

Ring Gauge Influence on Cigar Aging Potential and Storage SolutionsNewsJun.26,2025

-

Pin Gauge Training Programs for Enhanced Dimensional Inspection SkillsNewsJun.26,2025

-

Custom Spline Ring Gauge Design for Unique Engineering NeedsNewsJun.26,2025

-

Cost-Effective Alternatives to Custom Threaded Ring GaugesNewsJun.26,2025

Related PRODUCTS