Oct . 31, 2024 20:23 Back to list

Different Types of Strainers and Their Uses in Various Applications

Types of Strainers Understanding Fluid Filtration

Strainers play a critical role in various industries, facilitating the efficient flow of liquids while preventing the entry of unwanted materials. These devices are essential for maintaining the integrity of pumps, valves, and other equipment in systems ranging from water treatment to food processing. Understanding the different types of strainers and their applications is vital for optimizing performance and longevity in fluid handling systems.

1. Basket Strainers

Basket strainers are one of the most common types of strainers used in industrial applications. They consist of a cylindrical body with a perforated or mesh basket inside that captures debris as fluid flows through. The design allows for easy cleaning and maintenance, as the basket can be removed and cleaned or replaced without disrupting the entire system. They are particularly effective in applications with high flow rates and are widely used in water filtration, chemical processing, and HVAC systems.

2

. Y-StrainersY-strainers are another popular choice known for their compact design, resembling the letter Y. This type of strainer is installed in pipelines to filter out impurities. What sets Y-strainers apart is their ability to be installed in either horizontal or vertical positions, providing flexibility in various setups. They are particularly useful in systems where space is limited. Maintenance is relatively straightforward, as a threaded cap allows for easy access to the strainer element for cleaning or replacement.

3. Temporary Strainers

types of strainer

As the name implies, temporary strainers are used for short durations, usually during construction or maintenance work. They are often made of a simple perforated screen or mesh that can easily be installed and removed. Their primary function is to protect downstream equipment from debris during system start-up, cleanouts, or repairs. Though not intended for long-term use, they are invaluable for ensuring system integrity during transitional phases.

4. Inline Strainers

Inline strainers are designed to fit directly into pipelines, maintaining a streamlined flow while providing effective filtration. They come in various configurations, including threaded or flanged connections, to accommodate different piping systems. Inline strainers are ideal for protecting pumps and other machinery from particulate matter by offering a low-pressure drop and high filtration efficiency, making them suitable for many industrial applications.

5. Magnetic Strainers

In industries where metallic contaminants can pose significant risks, magnetic strainers offer a specialized solution. These devices incorporate magnets into the filtration system to attract and capture ferrous particles that traditional strainers might miss. They are particularly effective in food processing, pharmaceutical production, and any application where product purity is paramount.

Conclusion

Selecting the appropriate type of strainer is critical for the efficiency and safety of fluid systems. Whether it’s a robust basket strainer for high-flow applications or a temporary strainer for short-term uses, each type has its unique benefits and applications. Understanding these differences helps industries maintain optimal operation while safeguarding their equipment from potential damage caused by contaminants. Investing in the right strainer type not only enhances system performance but also prolongs the life of costly machinery.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

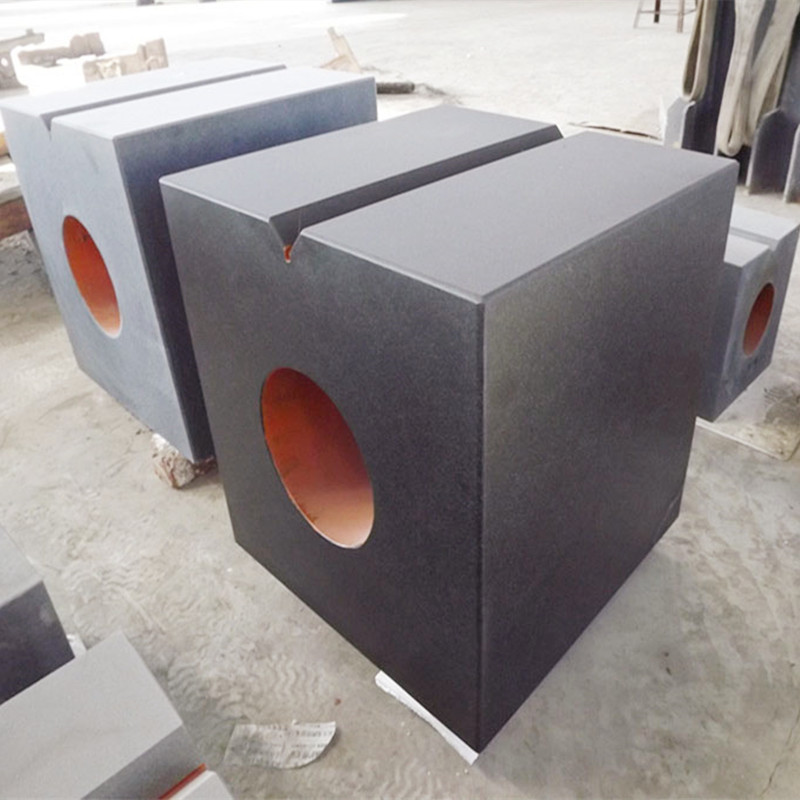

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS