Jul . 28, 2025 09:25 Komawa zuwa lissafi

Installation Best Practices for Butterfly Valves 6 inch

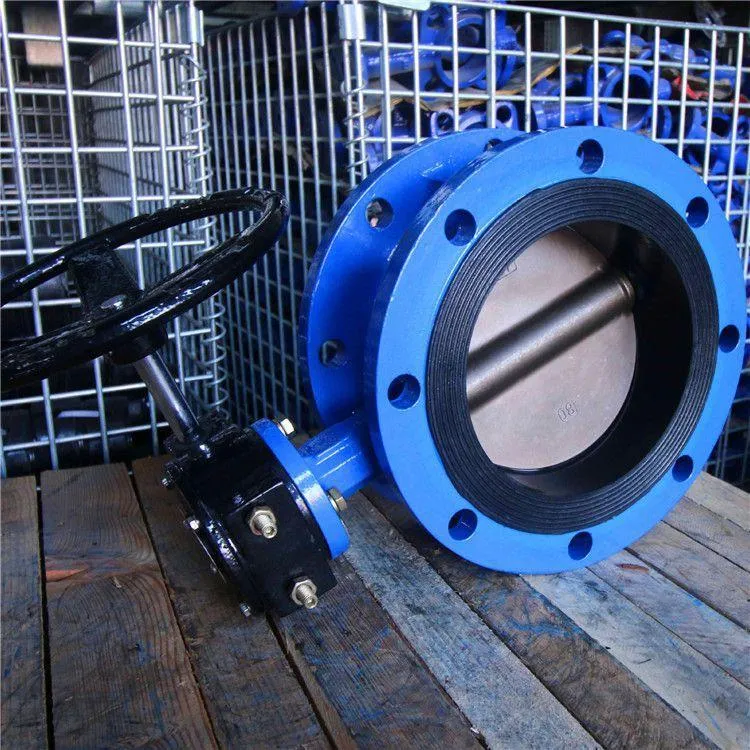

The ubiquitous butterfly valve 6 inch is a cornerstone of industrial flow control, prized for its efficiency, compactness, and cost-effectiveness. However, its reliable performance and extended service life are intrinsically linked to correct installation and diligent maintenance. For wholesale procurement managers and plant engineers sourcing butterfly valve for sale in bulk, understanding these best practices is not just beneficial – it's essential for minimizing downtime, preventing costly failures, and maximizing the return on investment for these critical components. Improper handling can negate the inherent advantages of the butterfly valve 6 inch, leading to leaks, operational issues, and premature replacement demands. This guide outlines the crucial steps and considerations for ensuring these valves perform flawlessly from the moment they leave the supplier to years of dependable service.

Pre-Installation Butterfly Valves Preparation: Setting the Stage for Success

Success begins long before the wrench touches the flange. Thorough preparation ensures a smooth installation and prevents avoidable problems:

- Valve Inspection & Verification:Upon receiving your wholesale shipment of butterfly valve 6 inch units, conduct a meticulous inspection. Check for any visible damage sustained during transit. Verify the material specifications (body, disc, seat), pressure rating, end connection type , and seat material against the purchase order and project requirements. Ensure protective covers are intact.

- Flange Readiness & Alignment:Inspect the pipe flanges meticulously. They must be clean, undamaged, parallel, and perfectly aligned. Misalignment is a primary cause of seat distortion and leakage in butterfly valves. Ensure adequate space exists around the valve for installation, operation (including actuator swing), and future maintenance access.

- Gasket Selection:Choose the correct gasket material and type compatible with the process fluid, temperature, and pressure. Ensure the gasket inner diameter matches the valve bore to avoid flow restriction. Never reuse old gaskets.

- Actuator Considerations:If the valve is supplied without an actuator but will be automated later, confirm the mounting pad compatibility and torque requirements. If actuators are included in the butterfly valve for sale shipment, verify they are correctly sized for the valve's operating torque under the specific process conditions.

Proactive Maintenance Regimens for Butterfly Valve Longevity

Regular, proactive maintenance is the key to unlocking the full lifespan potential of your butterfly valves, especially crucial when managing large inventories purchased wholesale:

- Operational Cycling:Regularly exercise valves, especially those in standby service or operating infrequently . Open and close them fully several times quarterly to prevent sticking, keep seats lubricated (if applicable), and ensure the stem turns freely. This is vital for valves sourced via butterfly valve for saledeals that might sit in inventory before deployment.

- Visual Inspections:Conduct routine visual inspections for external leaks (flange connections, stem seals), signs of corrosion, physical damage, or excessive buildup on the valve body. Check actuator linkages for security and signs of wear.

- Lubrication (Stem & Gearbox):Follow the manufacturer's recommendations for stem lubrication intervals and grease type. Lubricate the stem packing through the grease fitting (if equipped) to maintain seal integrity and reduce operating torque. For gear-operated butterfly valve 6 inch units, check and replenish gearbox oil as specified.

- Actuator Maintenance:Include actuator inspection and maintenance as part of the routine. Check pneumatic lines for leaks, electrical connections for integrity, limit and torque switch settings, and lubrication points on mechanical actuators. Ensure smooth and complete valve stroking.

- Record Keeping:Maintain detailed maintenance logs for each valve, recording inspections, lubrication, operational issues, repairs, and replacements. This history is invaluable for predicting failures and planning wholesale reorders of butterfly valve 6 inch spares.

Procuring for Performance: Wholesale Considerations Impacting Butterfly Valve Maintenance

The choices made during the wholesale procurement phase directly influence the ease and frequency of future maintenance:

- Standardization is Key:Specify standardized butterfly valve 6 inchdesigns across your operations whenever possible. Consistent materials, seat types, end connections, and actuator interfaces drastically simplify spare parts inventory, technician training, and repair procedures. This is a major advantage when sourcing butterfly valve for sale in bulk.

- Accessibility Features:Prioritize valves designed with maintenance in mind. Features like a top-entry design (allowing seat replacement without removing the valve body from the line) or easily accessible lubrication points significantly reduce downtime and labor costs during servicing.

- Spare Parts Availability:When placing large wholesale orders for butterfly valve 6 inch valves, negotiate the concurrent supply of critical spare parts kits (seats, seals, stem packing, gaskets) at favorable rates. Ensure the manufacturer commits to long-term spare parts support.

- Quality Documentation:Demand comprehensive documentation with each wholesale shipment: detailed dimensional drawings, material certifications, pressure test reports, installation, operation, and maintenance manuals, and clear lubrication specifications. This information is vital for correct installation and future maintenance planning.

Frequently Asked Questions on Butterfly Valve 6 Inch Care

Why is flange alignment so critical during butterfly valve 6 inch installation?

Perfect flange alignment is paramount because misalignment forces the valve body out of its true circular shape when bolts are tightened. This distortion directly impacts the valve seat – a precision component designed to seal against the disc. Even minor distortion can create gaps or uneven pressure on the seat, leading to leaks (both internal and external), premature seat wear, increased operating torque, and potential damage to the disc edge. Proper alignment ensures uniform compression and optimal sealing.

How often should I lubricate the stem on a manual butterfly valve 6 inch?

The lubrication interval depends heavily on the operating frequency, service conditions (temperature, media), and the specific stem packing design. A general guideline is to lubricate the stem packing every to months for valves in regular service, or before returning a long-idle valve to service. Always consult the manufacturer's manual for the specific valve. Use only the recommended grease type. Over-lubrication can be as detrimental as under-lubrication.

Can I repack a leaking stem seal on a butterfly valve 6 inch under pressure?

Absolutely not. Attempting to repack a stem seal or gland follower while the valve is under pressure is extremely hazardous. The pressurized fluid could be released violently, causing serious injury. The valve must be isolated (upstream and downstream), depressurized, drained (and verified), and locked out/tagged out before any maintenance on the stem seal is performed. Always follow strict plant safety procedures.

What are the most common signs that a butterfly valve 6 inch seat needs replacement?

Fluid passing through the valve when it is commanded to be fully closed (during a leak test or observed in-line).

Is it cost-effective to repair a butterfly valve 6 inch, or should I just replace it wholesale?

Resilient-seated wafer or lug butterfly valve 6 inch valves are often very economical to repair by replacing the seat/disc assembly and stem seals. A cost-benefit analysis per valve is recommended. Having spare valves or kits sourced via butterfly valve for sale programs facilitates either approach.

At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide. Situated amidst a bustling ecosystem of top-tier raw material suppliers and skilled labor, Storaen (Cangzhou) International Trading Co. gains a competitive edge, ensuring access to premium resources that fuel its manufacturing prowess. This commitment to precision engineering and quality assurance translates directly to their butterfly valve offerings. Valves procured wholesale from such a source inherently benefit from consistent manufacturing tolerances, robust material choices, and adherence to international standards – fundamental factors that significantly contribute to easier installation, smoother operation, and reduced long-term maintenance demands for butterfly valve 6 inch applications. Choosing a supplier with this embedded quality culture is a strategic decision for minimizing lifecycle costs.

-

V Blocks for Sale: Types, Uses, and Best Heavy-Duty Frame V OptionsLabaraiJul.28,2025

-

The Process of Creating Precision Granite Stone BlocksLabaraiJul.28,2025

-

Key Factors When Selecting Ball Valves for SaleLabaraiJul.28,2025

-

How Seat Material Affects Performance in Butterfly Valve ApplicationsLabaraiJul.28,2025

-

Guide to Plain Ring Gages for Industrial Quality ControlLabaraiJul.28,2025

-

4 Flanged Y Strainer Configurations for Heavy-Duty SystemsLabaraiJul.28,2025

Kayayyakin da suka danganci