Jul . 10, 2025 09:27 Komawa zuwa lissafi

Cast Iron Surface Plate Resists Warping Over Time

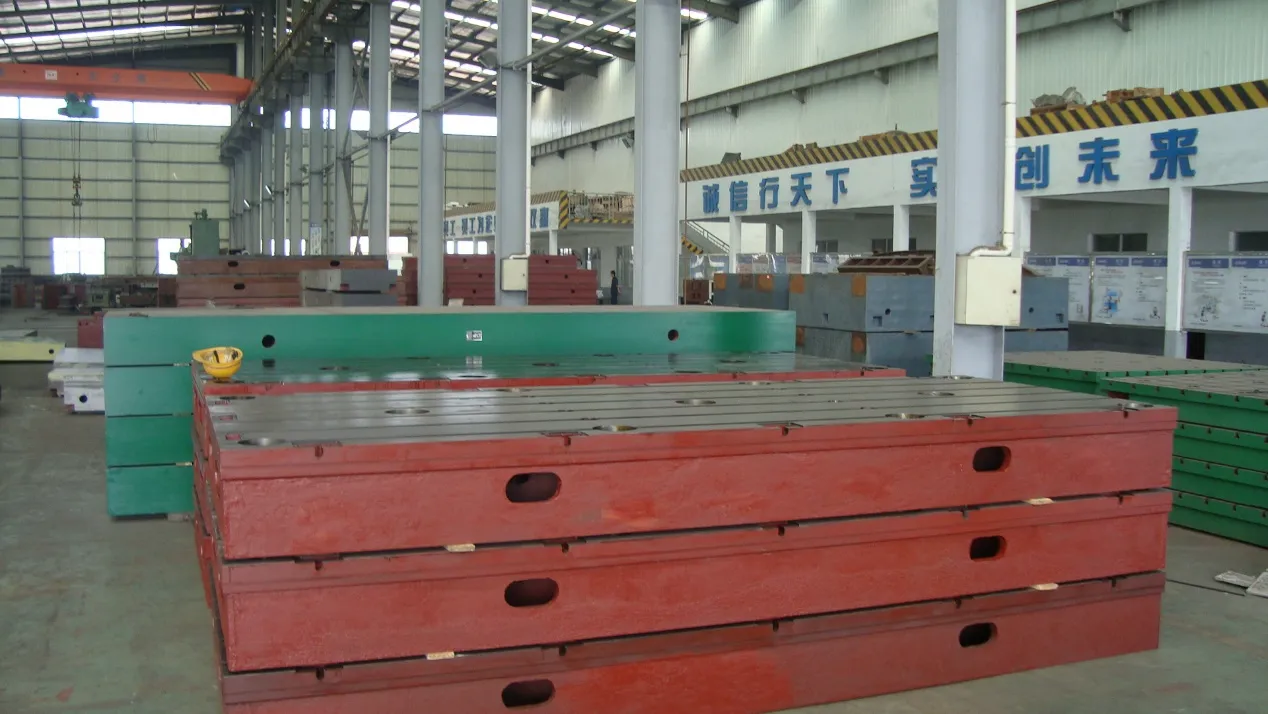

In the realm of metal fabrication and precision work, the stability of work surfaces is of utmost importance. A warped surface can lead to inaccuracies in measurements, poor - quality workmanship, and ultimately, wasted time and resources. Storaen (Cangzhou) International Trading Co. offers cast iron surface plate solutions that stand the test of time, resisting warping and providing a reliable foundation for various tasks. These plates are not only essential on their own but also play a crucial role when integrated into steel fab table setups, enhancing the overall performance and longevity of workshop equipment.

Storaen (Cangzhou) International Trading Co.’s Commitment to High - Quality Cast Iron Surface Plates

Storaen (Cangzhou) International Trading Co., based in Botou, China, has a long - standing reputation for manufacturing and supplying top - tier industrial products. When it comes to cast iron surface plate, our company is dedicated to using the finest materials and the most advanced manufacturing techniques. Our cast iron surface plate products undergo a meticulous production process, from the selection of high - quality cast iron raw materials to the precision machining and heat treatment stages. This commitment ensures that each plate meets the highest standards of flatness, hardness, and dimensional stability, making them a trusted choice for professionals in the metal fabrication industry.

|

Parameter |

Value |

|

Place of Origin |

Hebei, China |

|

Warranty |

1 year |

|

Customized support |

OEM, ODM, OBM |

|

Brand Name |

Storan |

|

Model Number |

2011 |

|

Kayan abu |

cast iron (also HT200 - 300, QT or steel) |

|

Accuracy |

customized |

|

Operation Mode |

customized |

|

Item Weight |

customized |

|

Capacity |

customized |

|

Product name |

Cast Iron Surface Plate |

|

Girman |

200x200 - 4000x8000mm or customizable |

|

Hardness of Working Surface |

HB160 - 240 |

|

Tsarin tushe |

guduro yashi simintin gyaran kafa |

|

Structure |

rib (bone) structure with enough wall thickness |

|

Zane |

primer and face paint |

|

Madaidaicin daraja |

0 - 3 |

|

Yanayin aiki |

(20±5) °C |

|

Marufi |

akwatin plywood |

Integration of Cast Iron Surface Plates in Steel Fab Tables

When integrated into steel fab table designs, cast iron surface plate significantly enhances the functionality and durability of the tables. The sturdy steel frame of the steel fab table provides a robust support structure, while the cast iron surface plate offers a flat, stable, and warp - resistant work surface. This combination is particularly beneficial in welding and heavy - duty fabrication tasks, where the table needs to withstand high temperatures, heavy loads, and mechanical stresses. The cast iron surface plate on a steel fab table ensures that the work surface remains true over time, allowing for precise positioning and assembly of metal components.

Applications of Cast Iron Surface Plates in Diverse Industries

- The versatility of cast iron surface platesmakes them applicable across a wide range of industries.

- In the automotive industry, they are used for precise assembly and inspection of engine components and body parts.

- In aerospace manufacturing—where the highest precision is required—cast iron surface platesprovide a reliable platform for fabricating aircraft parts.

- In general metal fabrication workshops, they serve as essential tools for layout work, checking the flatness of metal sheets, and ensuring the accuracy of complex metal structures.

- Whether in large-scale industrial production or small-scale custom fabrication, cast iron surface platesplay a vital role.

Cast Iron Surface Plate FAQS

How does heat treatment contribute to the warp - resistance of cast iron surface plates?

Heat treatment is a critical process in enhancing the warp - resistance of Storaen (Cangzhou) International Trading Co.’s cast iron surface plate. During heat treatment, the cast iron is heated to a specific temperature and then cooled slowly. This process relieves internal stresses that are generated during the casting and machining stages. By eliminating these stresses, the plate is less likely to warp over time. The heat treatment also refines the microstructure of the cast iron, improving its mechanical properties and overall stability.

Can a cast iron surface plate be used outdoors?

Yes, our cast iron surface plate can be used outdoors. Cast iron is a durable material that is resistant to many environmental factors. While it is not completely immune to the effects of prolonged exposure to moisture and extreme temperatures, proper maintenance can mitigate these risks. Applying a protective coating, such as paint or rust - inhibiting oil, and covering the plate when not in use can help ensure its longevity even in outdoor settings. However, for the best performance and to maintain precision, indoor use is recommended.

How do cast iron surface plates benefit steel fab tables?

Cast iron surface plate brings several benefits to steel fab table. The flat and stable surface of the cast iron plate provides a reliable work area for welding, cutting, and other fabrication tasks. Its warp - resistance ensures that the table maintains accuracy over time, which is essential for repeatable and precise work. The high hardness of the cast iron also protects the table from damage caused by heavy tools and metal components, extending the lifespan of the steel fab table and reducing the need for frequent repairs or replacements.

What maintenance is required for cast iron surface plates?

Maintenance of cast iron surface plate is relatively straightforward. Regularly clean the surface with a soft brush or cloth to remove metal shavings, debris, and any corrosive substances. Apply a thin layer of protective oil to prevent rust, especially if the plate is not in constant use. Periodically check the surface for any signs of wear or damage. If the surface becomes slightly uneven over time, professional resurfacing services can be employed to restore its flatness. Following these simple steps will keep the cast iron surface plate in optimal condition.

Are there different sizes of cast iron surface plates available?

Yes, Storaen (Cangzhou) International Trading Co. offers a wide range of sizes for our cast iron surface plate products. We understand that different workshops and applications have varying requirements. Whether you need a small plate for bench - top use or a large one for industrial - scale projects, we have options to meet your needs. Additionally, we can provide customized size solutions to ensure that the cast iron surface plate fits perfectly into your steel fab table or metal fabrication table setup and supports your specific work processes.

-

Thread Plug Gauge Our Promise of Measurement ExcellenceLabaraiAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyLabaraiAug.22,2025

-

Check Valve Types for High Rise BuildingsLabaraiAug.22,2025

-

Water Control Valve for Irrigation SystemsLabaraiAug.22,2025

-

Gate Valve with Soft Seal TechnologyLabaraiAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsLabaraiAug.22,2025

Kayayyakin da suka danganci