નવેમ્બર . 25, 2024 03:46 Back to list

type of micrometre

Understanding the Types of Micrometers Precision Instruments for Measurement

Micrometers are essential tools used in various fields, including mechanical engineering, manufacturing, and physics, for measuring small distances with high precision. The adaptability and accuracy of micrometers make them invaluable in quality control and research applications. In this article, we will explore the different types of micrometers, their specific uses, and how they contribute to precision measurement.

What is a Micrometer?

A micrometer, often referred to as a micrometer screw gauge, is a device that allows for precise measurements typically in the range of millimeters to micrometers (one millionth of a meter). The fundamental working principle of a micrometer involves a calibrated screw mechanism that translates linear motion into precise rotational movement. This enables users to measure small dimensions with an accuracy of 0.01 mm or better.

Types of Micrometers

Micrometers come in several types, each designed for specific measurement tasks. Here are the most common types

1. Outside Micrometer This is the most widely used type of micrometer. It is designed for measuring the external dimensions of an object, such as the diameter of rods and the thickness of materials. The outside micrometer consists of a U-shaped frame with a movable jaw that is operated by turning the thimble. The measurement is read on a scale, allowing for highly accurate readings.

2. Inside Micrometer Unlike its outside counterpart, the inside micrometer is used to measure the internal dimensions of objects, such as holes, tubes, and other cylindrical shapes. It comes with a pair of interchangeable measuring anvils or rods which can be adjusted to suitable sizes. Inside micrometers often have a long reach, enabling the measurement of deeper cavities.

type of micrometre

3. Depth Micrometer This type of micrometer is specifically designed to measure depths, such as the depth of holes or slots. It features a measuring blade that extends vertically from the main frame. Users can slide the blade into the depth to reach the bottom of the cavity, and the reading is displayed on a scale much like an outside micrometer. Depth micrometers are especially useful in machining and engineering applications.

4. Digital Micrometer As technology advances, digital micrometers have gained popularity. These devices feature an electronic display that provides instantaneous readings, eliminating the possibility of parallax errors associated with traditional mechanical scales. Digital micrometers may also include features such as data output, which aids in transferring measurement data to computers or other devices for further analysis.

5. Spline Micrometer This specialized micrometer is tailored for measuring the curvature or diameter of spline shapes, often found in automotive and machinery parts. Spline micrometers come with unique measuring heads that fit into the grooves of splines, allowing for accurate measurements of their profiles.

The Importance of Micrometers

Precision measurement is crucial in many industrial and research applications. The accuracy provided by micrometers ensures that components fit together correctly, maintain desired performance, and meet stringent quality standards. For instance, in the manufacturing sector, even a tiny deviation can lead to significant operational issues or product failures. Thus, using the right type of micrometer not only guarantees accuracy but also enhances efficiency and safety.

Conclusion

Micrometers play a significant role in the fields of engineering and manufacturing by providing precise measurements that are critical for quality control and product development. Understanding the various types of micrometers—outside, inside, depth, digital, and spline micrometers—enables professionals to select the appropriate tool for their specific measurement needs. Through the use of these instruments, industries can maintain high standards of precision, paving the way for innovations and enhancements across technology and engineering fields.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

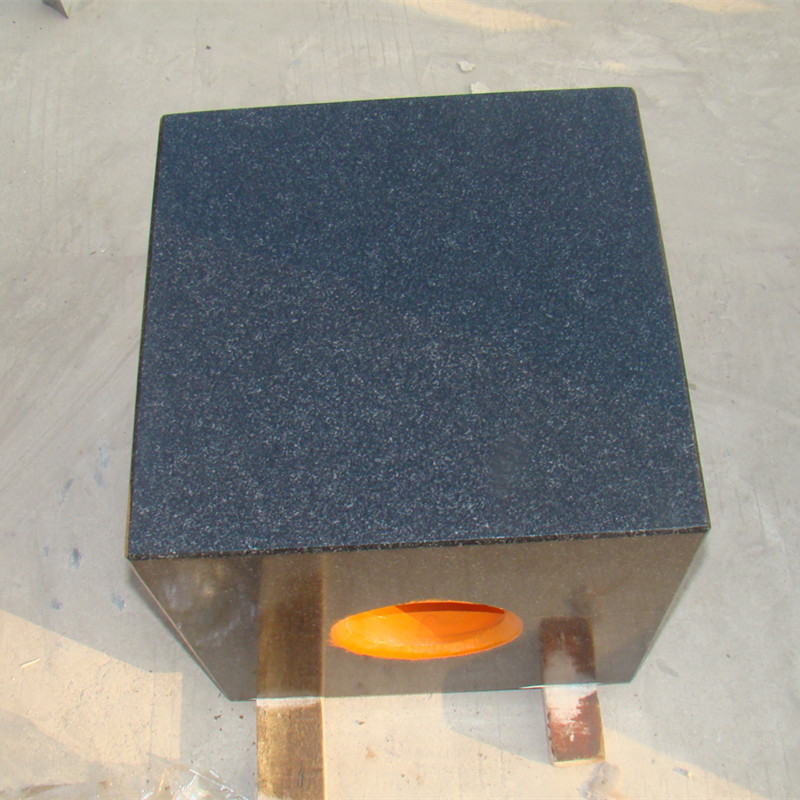

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS