ડીસેમ્બર . 27, 2024 21:06 Back to list

thread plug gauge 6g

Understanding the Thread Plug Gauge 6g Essential Tool for Quality Control

In the realm of manufacturing and engineering, precision is paramount. One of the critical aspects of ensuring quality in threaded components is the usage of thread gauges. Among these, the thread plug gauge, particularly designated as 6g, plays a significant role in verifying the accuracy and functionality of threaded parts. This article delves into the importance, specification, and application of the thread plug gauge 6g.

What is a Thread Plug Gauge?

A thread plug gauge is a specialized measuring tool used to check the pitch diameter and, in some cases, the major diameter of internal threads. Unlike other thread measuring instruments, a plug gauge is designed to fit into a tapped hole, allowing manufacturers to assess whether the threads conform to specified tolerances. Thread plug gauges are referred to by their tolerances—such as 6g—indicating the precision limits they are designed to meet.

Understanding the 6g Tolerance

The designation 6g refers to a specific tolerance class in the metric thread system, which is governed by international standards like ISO and DIN. The 6 signifies the basic size, while the g indicates the tolerance grade. In the context of internal threads, a 6g tolerance indicates a medium degree of fit, suitable for many applications where moderate precision is acceptable. This tolerance class is particularly common for general engineering applications, providing a balance between ease of assembly and reliability in operation.

Importance of Using 6g Thread Plug Gauges

Utilizing a 6g thread plug gauge is essential for ensuring the integrity of threaded components

. Here are the primary reasons why this tool is pivotal in manufacturingthread plug gauge 6g

1. Quality Assurance Measuring the internal threads with a 6g plug gauge helps ensure that parts meet the design specifications. This guarantees the components will fit correctly during assembly, preventing issues related to misalignment or mechanical failure.

2. Efficiency in Production With the ability to quickly assess the dimensional accuracy of threaded holes, production times can be optimized. A straightforward and reliable measurement process allows for rapid feedback and adjustment, ensuring the manufacturing process remains efficient.

3. Interchangeability Standardized thread dimensions promote interoperability between various suppliers and manufacturers, which is particularly crucial in industries like automotive and aerospace where precision is key. The 6g tolerance allows for the assurance of part compatibility.

4. Cost-Effectiveness By reducing the likelihood of defects and rework, using a 6g thread plug gauge contributes to lower production costs. A proactive approach to quality assurance minimizes waste and maximizes resource utilization.

Applications Across Industries

Thread plug gauges, including the 6g type, find applications in a diverse range of industries. From automotive manufacturing to aerospace engineering, and even in machinery, these gauges ensure that components like bolts, screws, and other fasteners meet necessary standards. Their use is not limited to large-scale production; they are equally valuable in small workshops where precision machining takes place.

Conclusion

In conclusion, the thread plug gauge 6g stands as a vital instrument in the toolkit of quality assurance within manufacturing. Its role in verifying the accuracy of internal threads helps ensure product reliability while maintaining operational efficiency. As industries continue to evolve, the significance of precision measurement tools like the 6g thread plug gauge cannot be overstated. Understanding and utilizing this gauge is essential for manufacturers striving for excellence and consistency in their products. Whether in the design phase or during production, the thread plug gauge 6g proves indispensable for achieving high-quality outcomes in threaded components.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

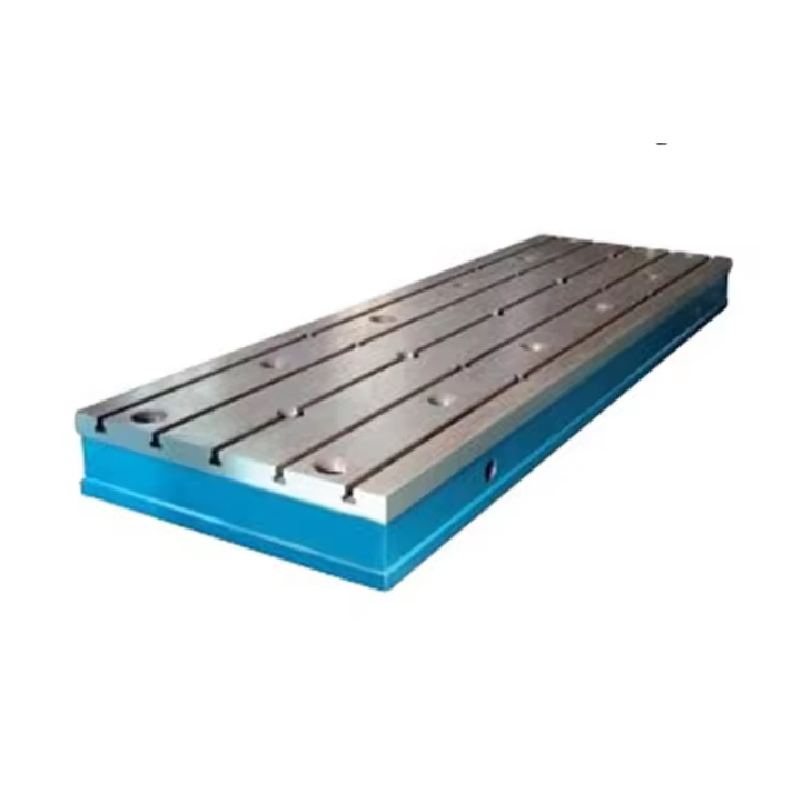

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS