ડીસેમ્બર . 28, 2024 00:26 Back to list

plain plug gauge

Understanding Plain Plug Gauges A Comprehensive Overview

Plain plug gauges play a crucial role in the realm of precision measurement, particularly in the manufacturing and engineering sectors. These simple yet effective tools are designed to measure the dimensions of holes, ensuring that their diameters are within specified tolerances. By providing a quick and efficient means of verifying hole sizes, plain plug gauges help maintain the quality of manufactured parts and assemblies.

What is a Plain Plug Gauge?

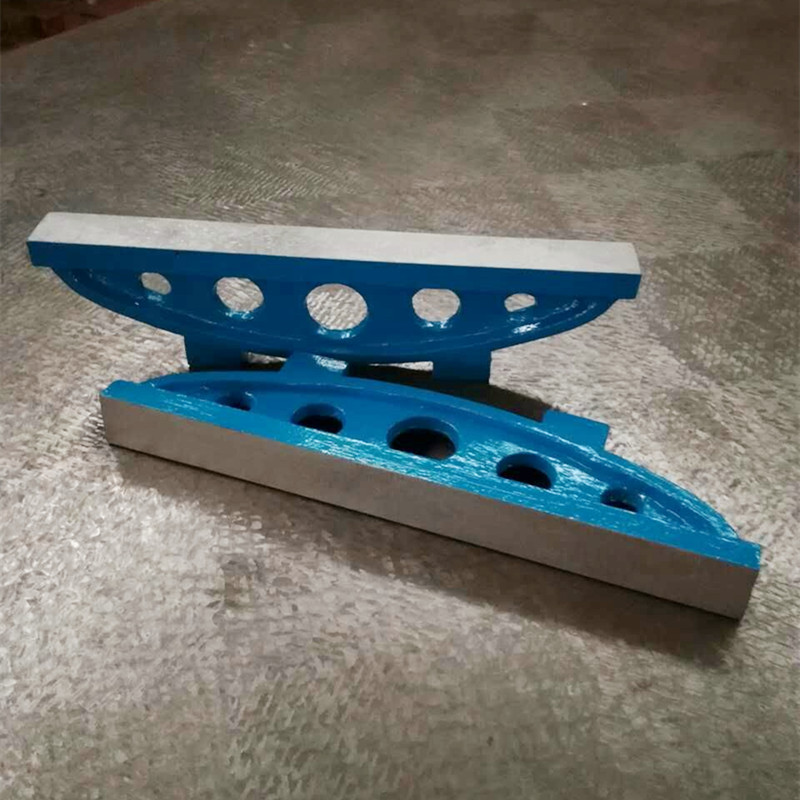

A plain plug gauge is a cylindrical tool made to fit into a hole of known size. Typically constructed from high-grade materials such as steel, these gauges are precision-engineered to meet stringent tolerances. The design of a plain plug gauge is straightforward; it features a smooth, cylindrical shape that allows it to be inserted into a hole for verification. There are generally two types of plain plug gauges go gauges and no-go gauges.

- Go Gauge This part is designed to fit perfectly into the hole at the maximum allowable size. If the go gauge fits, it indicates that the hole is acceptable and within tolerance. - No-Go Gauge Conversely, the no-go gauge is slightly larger than the permissible size of the hole. If the no-go gauge does not fit, it confirms that the hole is not larger than the specified limit.

Importance in Manufacturing

The significance of plain plug gauges in manufacturing cannot be overstated. They serve multiple purposes

1. Quality Control Plain plug gauges are indispensable in quality assurance processes. They help ensure that parts produced are of the correct dimensions, which is critical for parts that must fit together in assemblies.

plain plug gauge

2. Cost Efficiency Using plug gauges effectively reduces inspection time and identifies defective parts early in the production process. This capability helps avoid the expenses associated with rework or scrap.

3. Standardization Plug gauges promote standardization in manufacturing processes. By adhering to set dimensional tolerances, manufacturers can ensure uniformity across production lines.

Types of Materials Used

The accuracy and durability of plain plug gauges depend significantly on the materials used in their construction. High-carbon steel is commonly employed because of its hardness and resistance to wear. Additionally, some plug gauges are made from stainless steel or carbide for enhanced durability and resistance to corrosion. The choice of material often hinges on the specific application and environmental factors in which the gauge will be utilized.

Calibration and Maintenance

Like any precision measuring tool, plain plug gauges require regular calibration and maintenance to ensure their accuracy. Calibration involves checking the gauges against certified standards and making necessary adjustments. Proper storage is also important; gauges should be stored in protective cases to prevent physical damage and contamination. It is advisable to inspect plug gauges routinely for signs of wear or damage, as even the slightest deformation can lead to inaccurate measurements.

Conclusion

In conclusion, plain plug gauges are essential tools in the manufacturing sector, offering an efficient means of ensuring the dimensional accuracy of holes within parts. By facilitating rigorous quality control measures, enhancing cost efficiency, and promoting standardization, they play a pivotal role in the production process. Understanding their function and importance, as well as ensuring proper maintenance and calibration, can significantly contribute to the success and precision of manufacturing operations. As industries increasingly strive for quality and efficiency, the role of plain plug gauges remains more relevant than ever in achieving these goals.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS