ડીસેમ્બર . 07, 2024 10:05 Back to list

Versatile Applications of Magnetic V Blocks in Precision Machining and Setup

The Versatile Uses of Magnetic V Blocks in Precision Engineering

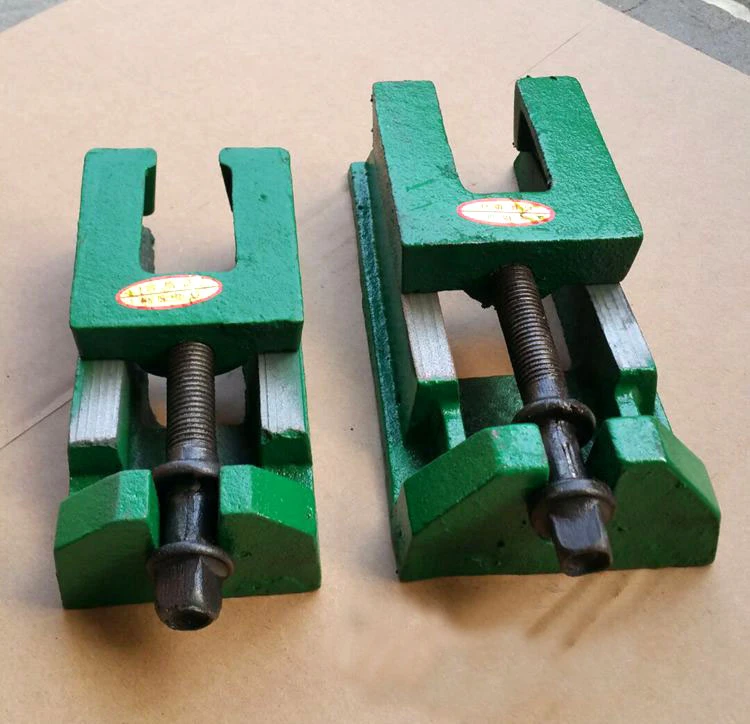

Magnetic V blocks are essential tools in the realm of precision engineering, offering a unique combination of versatility, accuracy, and efficiency. Their design, typically featuring a V-shaped groove for securely holding cylindrical and round objects, allows for a wide array of uses, particularly in metalworking, manufacturing, and inspection processes.

What is a Magnetic V Block?

A magnetic V block is a sturdy block with a V-shaped notch that is equipped with a powerful magnet. This tool is designed to hold workpieces, especially cylindrical parts, in a secure position during various operations such as milling, grinding, inspection, or assembly. The strong magnetic force of the block ensures that the workpiece remains stable, allowing for precise machining and measurement.

Applications in Precision Machining

One of the primary applications of magnetic V blocks is in precision machining tasks. When working with cylindrical components, it is crucial to hold them securely to maintain accuracy. Magnetic V blocks can easily hold these components in place, minimizing the risk of movement during cutting, grinding, or measuring processes. This stability leads to enhanced surface finishes and dimensional accuracy and reduces the chances of wastage or rework.

Inspection and Quality Control

In quality control and inspection processes, magnetic V blocks play a significant role. When measuring cylindrical components, the accuracy of the measurement is critical. Magnetic V blocks provide a stable platform to hold the workpiece, allowing inspectors to use tools such as calipers or micrometers to obtain precise measurements. The magnetic adhesion eliminates the movement that can lead to errors, thus ensuring that the measurements are reliable and repeatable.

magnetic v block uses

Versatility in Different Work Environments

The versatility of magnetic V blocks makes them beneficial in various work environments, including workshops, assembly lines, and laboratories. Their portability and ease of use allow engineers and technicians to quickly set up and adjust the blocks for different tasks, leading to improved workflow efficiency. Whether used on a milling machine, lathe, or inspection table, these blocks can accommodate a wide range of workpieces.

Additional Features and Variants

Magnetic V blocks come in different sizes and styles to accommodate varying needs. Some are designed with additional features such as adjustable angles, additional clamping mechanisms, or even custom magnetic strengths, allowing users to choose a block that best suits their specific applications. Furthermore, some advanced models may include features that facilitate easy switching between manual and automatic patterns of attachment, making them even more versatile.

Safety and Ergonomics

Safety is paramount in any engineering environment, and magnetic V blocks contribute to a safer working condition. By securely holding workpieces in place, they help prevent accidents caused by loose or unstable components. Moreover, their ergonomic designs often feature handles or easy-grip surfaces to facilitate handling without exerting excessive force, thereby reducing operator fatigue.

Conclusion

In the domain of precision engineering, magnetic V blocks are invaluable tools that enhance accuracy, efficiency, and safety. Their ability to hold various workpieces securely while allowing for precise machining and inspection processes makes them a staple in manufacturing and quality control settings. As technology evolves and the demands for precision and efficiency increase, the versatility and functionality of magnetic V blocks will continue to make them indispensable in all areas of engineering. Whether you are a seasoned professional or a novice in the field, integrating a magnetic V block into your toolkit can greatly enhance your capability to perform precision tasks with confidence and accuracy.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS