ડીસેમ્બર . 16, 2024 01:24 Back to list

6 check valve

Understanding 6% Check Valves Essential Components in Fluid Control

Check valves are vital components in various piping systems where the prevention of backflow is crucial. Among the different types of check valves available, a 6% check valve occupies a unique niche in fluid dynamics. This article delves into the design, functionality, and applications of 6% check valves, highlighting their importance in industrial and domestic settings.

A check valve is a mechanical device that allows fluid to flow in one direction while preventing it from flowing backward. It operates automatically and requires no external control. The different configurations of check valves include spring-loaded, swing, and diaphragm types, each offering varying degrees of efficiency and suitability based on specific applications. The term 6% check valve may refer to a particular sizing, performance rate, or perhaps even a standard related to a specific industry, emphasizing its role in efficiently managing fluid flow.

Understanding 6% Check Valves Essential Components in Fluid Control

In terms of materials, 6% check valves can be constructed from various substances, including stainless steel, brass, PVC, and other robust materials. The choice of material depends on factors such as the fluid being transported, temperature ranges, and environmental conditions. For example, stainless steel check valves are often used in more corrosive environments due to their resilience against rust and degradation.

6 check valve

When selecting a check valve, several parameters should be considered, including the pressure rating, temperature range, and flow coefficient. The flow coefficient, often denoted as Cv, indicates the capacity of the valve to allow fluid flow. A 6% check valve's Cv rating will determine the pressure drop across the valve and its overall efficiency in the system. Engineers often refer to Cv tables and charts to match the correct valve with their specific needs, ensuring optimal performance.

6% check valves find extensive use in various applications. In wastewater treatment facilities, for instance, they prevent the backflow of treated water into the system, maintaining the integrity of the treatment process. Similarly, in HVAC systems, these valves prevent reverse flow that could disrupt the heating or cooling cycle. Additionally, they are commonly found in pump systems, maintaining unidirectional flow and protecting pumps from potential damage due to backflow.

Installation and maintenance of check valves, including 6% variants, are also crucial for ensuring their performance. Proper installation typically requires adherence to the manufacturer’s guidelines regarding orientation (horizontal or vertical), which can significantly affect operations. Regular maintenance checks are also essential; inspecting the valve for wear, corrosion, and debris build-up ensures that it operates within its intended parameters.

In conclusion, 6% check valves play a critical role in fluid control systems, safeguarding against backflow and ensuring system stability. Their design, material choice, and efficiency ratings make them indispensable in various applications, from industrial settings to everyday household systems. As industries continue to rely on the smooth operation of fluid transport systems, the significance of reliable components like the 6% check valve cannot be overstated. Understanding their functionality and maintaining their effectiveness will contribute to enhanced operational efficiency and longevity of the systems in which they are used.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

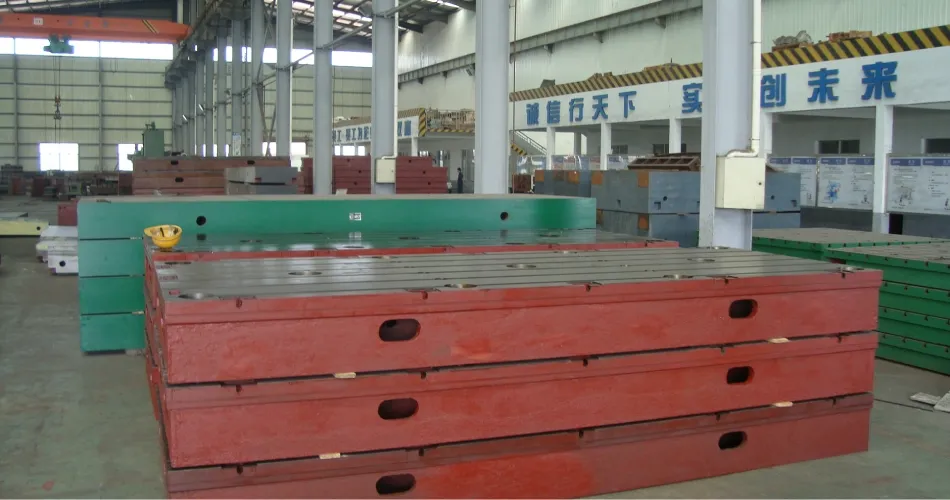

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS