Out . 11, 2024 19:55 Back to list

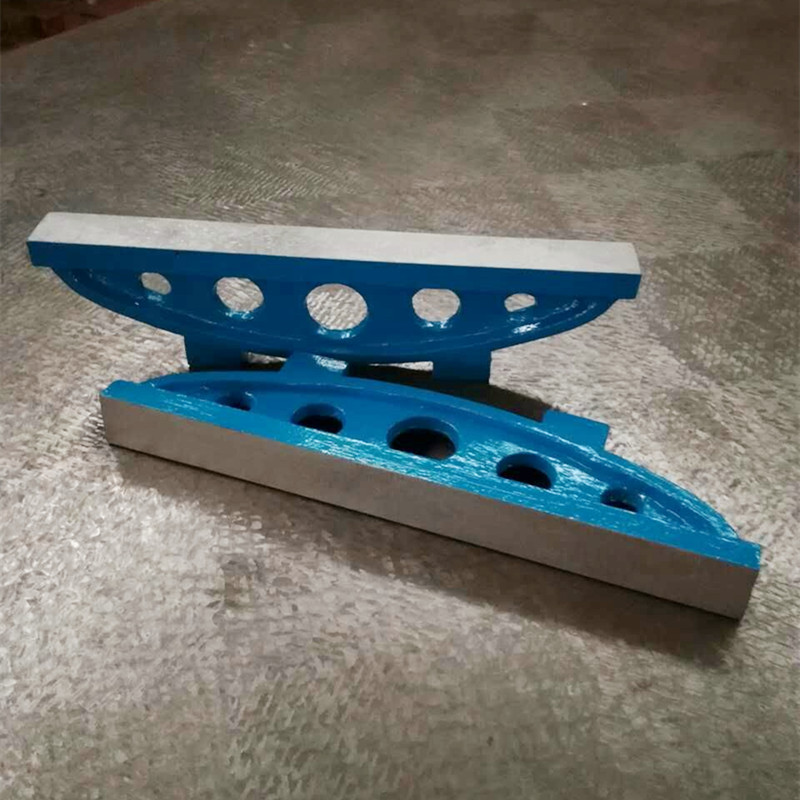

welding table clamps 5 8

Exploring Welding Table Clamps Essential Tools for Precision and Stability

Welding is an intricate process that requires precision, technique, and the right tools. Among these tools, welding table clamps play a crucial role in ensuring that your workpieces are securely held in place, allowing for accurate and effective welding. In this article, we will delve into the importance of welding table clamps, their types, and how to choose the right ones for your needs.

Welding table clamps are designed to secure metal pieces together while they are being welded. This is essential not just for maintaining the alignment of the pieces but also for ensuring safety during the welding process. By keeping the workpiece stable, these clamps prevent any movement that could lead to misalignment or defects in the welded joints.

Exploring Welding Table Clamps Essential Tools for Precision and Stability

Another popular option is the C-clamp, which is versatile and can be used in various applications beyond welding. C-clamps are ideal for securing irregularly shaped pieces because they can be easily adjusted to apply pressure on different areas. However, users should be cautious not to overtighten C-clamps, as this can distort the materials being worked on.

welding table clamps 5 8

Pipe clamps are specifically designed for holding cylindrical objects. They can accommodate various pipe sizes and are essential for projects that require welding pipes together. With their unique design, pipe clamps provide even pressure along the circumference of the pipe, ensuring a strong and stable weld.

For those involved in heavy-duty welding, specifically designed heavy-duty clamps are available. These clamps are built to withstand greater pressures and are perfect for large projects, ensuring that heavy materials remain firmly in place during the welding process.

When selecting welding table clamps, consider the size and weight of the materials you will be working with. It’s essential to choose clamps that can handle the specific dimensions and weight of your workpieces. Moreover, the material of the clamp itself is also important. Steel clamps are typically more durable and long-lasting, while aluminum clamps may be lighter but could lack the same level of strength.

In addition to the type and material of the clamps, think about the design and functionality. Look for clamps that are easy to operate and can accommodate quick adjustments. A good welding clamp should not only secure your workpieces effectively but also allow for a smooth workflow.

In conclusion, welding table clamps are indispensable tools that enhance the quality and safety of your welding projects. By understanding the different types of clamps available and selecting the right ones for your specific needs, you can ensure precise and stable work. Investing in quality clamps will ultimately lead to better results in your welding endeavors, making your projects more efficient and enjoyable. Remember, a well-held piece is half the battle won in the art of welding!

-

Types of Thread Gauge BSP Parallel DesignNewsAug.04,2025

-

Ring Gauge Cylindrical Check ApplicationNewsAug.04,2025

-

Machinist Gauge Pins GCr15 MaterialNewsAug.04,2025

-

Gate Valves for Sale Sewage System UseNewsAug.04,2025

-

Control Valve EPDM Seal MaterialNewsAug.04,2025

-

Cast Iron Y Type Strainer Flange Cover DesignNewsAug.04,2025

Related PRODUCTS