Out . 31, 2024 01:01 Back to list

precision bore gauge

Precision Bore Gauge Ensuring Measurement Accuracy in Engineering

In the world of engineering and manufacturing, precision is of utmost importance. Components need to fit together seamlessly to ensure optimal functionality. This is where precision bore gauges come into play. These specialized tools are designed to measure the internal diameters of holes in various materials, ensuring that they meet stringent specifications required for high-quality production.

A bore gauge consists of a measuring device that accurately assesses the internal diameter of a cylindrical surface, such as a hole or a pipe. Unlike traditional calipers, which can only provide limited measurements, a bore gauge offers a more comprehensive view of the internal structure. The gauge is typically equipped with telescoping rods or expandable measuring tips that can adapt to the size of the bore being measured.

One of the most important features of a precision bore gauge is its ability to provide measurements with a high degree of accuracy. Precision gauges often have a resolution of 0.001 mm or better, making them ideal for industries where even the smallest deviations can lead to significant issues. For instance, in the aerospace industry, components must adhere to tight tolerances to ensure safety and performance; a slight miscalculation could potentially result in catastrophic failures.

precision bore gauge

Using a precision bore gauge is a straightforward process, but it does require skill and care to ensure accurate results. The user first inserts the gauge into the hole being measured and expands the measuring tips until they make contact with the inner wall. This is followed by taking readings through a micrometer scale or a digital display. It’s crucial to handle the gauge with precision, as any error in measurement technique can lead to incorrect data, which could compromise the entire manufacturing process.

In addition to its accuracy, a precision bore gauge is favored for its versatility. Many models come with interchangeable tips that can accommodate various sizes and shapes, making them useful for a wide range of applications. From automotive parts to HVAC systems, precision bore gauges can be used in numerous industries. This adaptability is a significant advantage, as manufacturers can invest in one tool rather than multiple devices.

Moreover, advancements in technology have led to the development of digital and electronic bore gauges, which offer even greater accuracy and ease of use. These modern tools can automatically calibrate themselves, store multiple measurements, and even interface with computer systems for data analysis. This introduction of automation has not only increased measurement precision but also streamlined the manufacturing process, reducing the time spent on quality control.

In conclusion, precision bore gauges are indispensable tools in the realm of engineering and manufacturing. Their ability to measure internal diameters with a high degree of accuracy and their versatility across different applications make them essential in maintaining quality standards. As industries continue to evolve and push the boundaries of technological advancement, the reliance on precision instruments like bore gauges will only intensify. Investing in high-quality measurement tools ultimately leads to better products, fewer errors, and enhanced overall efficiency in the production process. Thus, for any organization that values precision and quality, the precision bore gauge is a fundamental asset.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

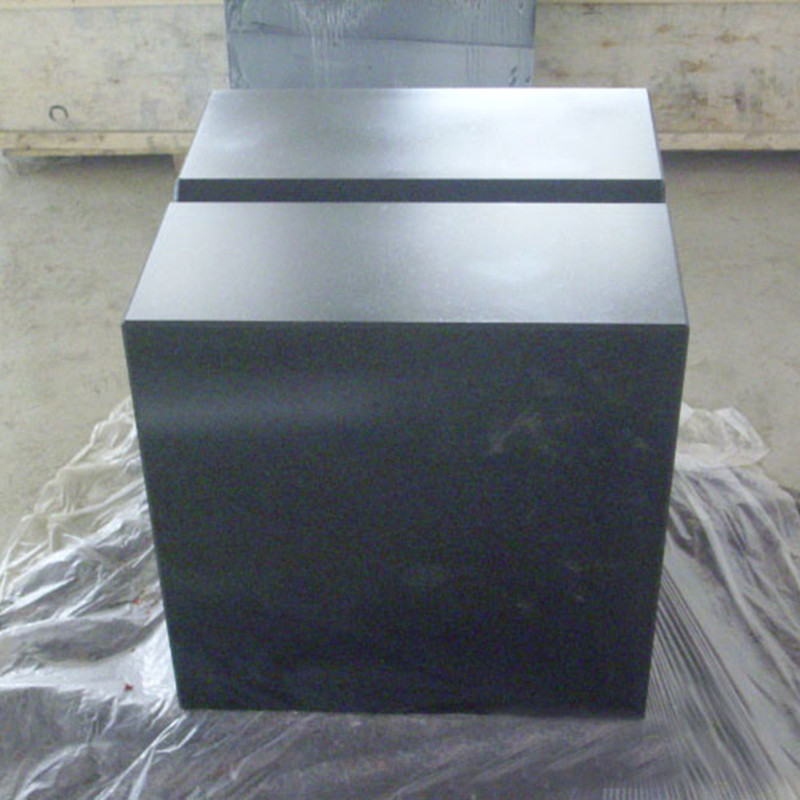

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS